GENERAL

5

Mexico Slimline CF440 -

Installation & Servicing

!

This position MUST also permit the provision of a

satisfactory flue and an adequate air supply.

!

For the minimum clearances required for safety and

subsequent service see Frame 2.

GAS SUPPLY

The local gas supplier should be consulted, at the installation

planning stage, in order to establish the availability of an

adequate supply of gas. An existing service pipe must NOT be

used without prior consultation with the local gas supplier.

The boiler is to be installed only on a gas supply with a

governed meter.

A gas meter can only be connected by the local gas supplier or

by a local regional contractor.

Check that the appliance is suitable for the proposed gas

supply. An existing meter should be checked, preferably by the

gas supplier, to ensure that the meter is adequate to deal with

the rate of gas supply required. A

minimum

gas pressure of

20mbar MUST be available at the boiler inlet, with the boiler

operating.

Installation pipes MUST be fitted in accordance with BS. 6891.

In IE refer to I.S. 813:2002. Pipework from the meter to the

boiler MUST be of an adequate size. Do not use pipes of a

smaller size than the boiler gas connection.

The complete installation MUST be tested for gas soundness

and purged as described in the above code.

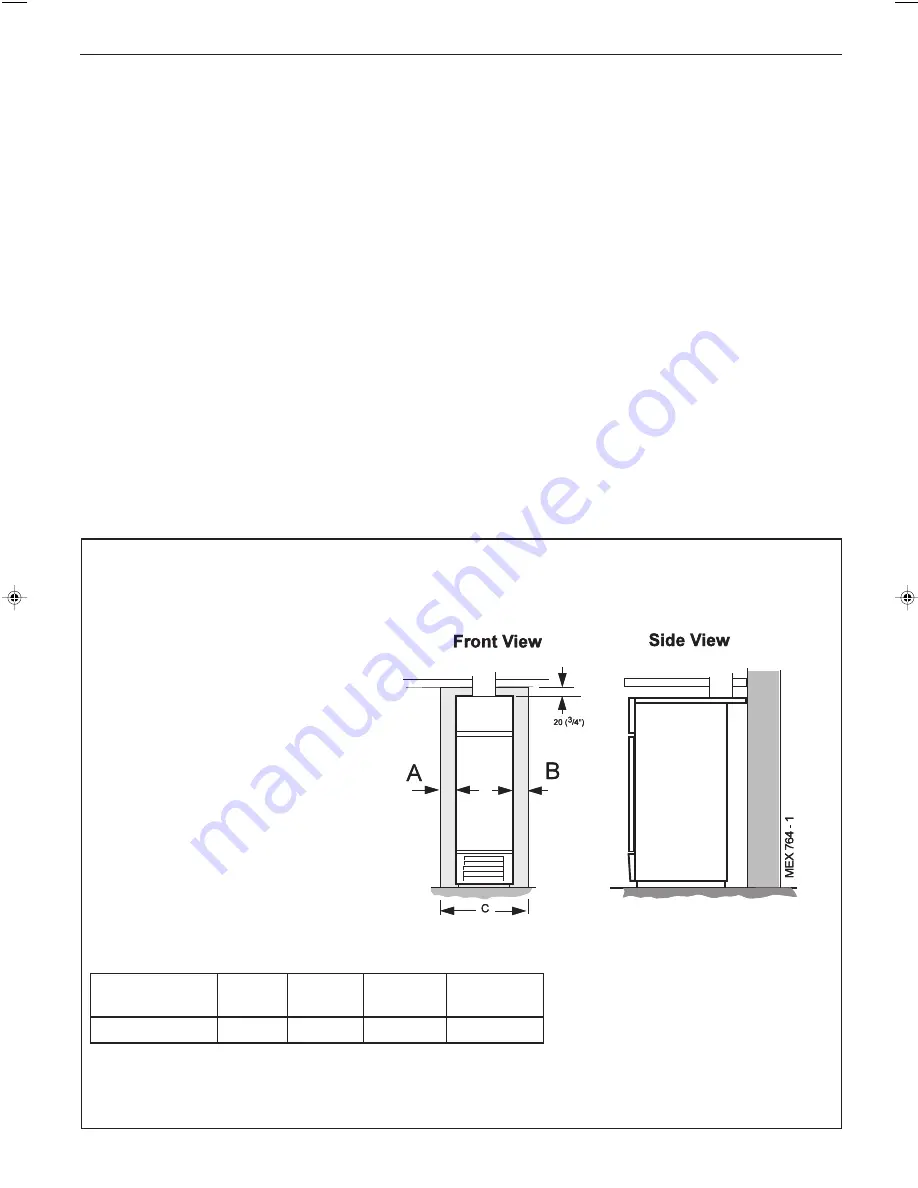

2 FLOOR MOUNTING AND BOILER CLEARANCES

Flammable materials must not be placed in

close proximity to the appliance. Materials

giving off flammable vapours must not be

stored in the same room as the appliance.

LOCATION OF BOILER

The boiler must be installed on a flat and level floor, capable of

adequately supporting the weight of the boiler and any ancillary

equipment.

The boiler may be fitted on a combustible floor.

Insulation is not necessary, unless required by the local authority.

The boiler must not be fitted outside.

The boiler must not be installed in a bedroom or in a room

containing a bath or shower.

Timber Framed Buildings

If the boiler is to be fitted in a timber framed building it should be

fitted in accordance with the Institute of Gas Engineering

document IGE/UP/7:1998.

Compartment Installations

A compartment used to enclose the boiler MUST be designed

and constructed specially for this purpose.

An existing cupboard or compartment may be used, providing it

is modified for the purpose.

Details of essential features of cupboards/compartment design,

including airing cupboard installation, are to conform to the

following:

!

!

!

!

!

BS. 6798.

!

!

!

!

!

The position selected for installation MUST allow

adequate space for servicing in front of the boiler

and for air circulation around the boiler.

FLOOR MOUNTING

1.

The floor must be flat, level and of

suitable load bearing capacity.

2.

The back of the boiler may be fitted

up to the wall.

BOILER CLEARANCES

The minimum overall dimensions of the space in which the

boiler is to operate and to facilitate servicing are as follows:

IMPORTANT.

A MINIMUM clearance of 25mm (1") MUST also be maintained

between the flue pipe and any adjacent combustible material.

In addition a MINIMUM clearance of 533 mm (21") MUST

be available at the front of the boiler, for servicing.

Boiler Clearances

Top

One side

Aggregate

Total

'A' or 'B'

'A' + 'B'

Width C

CF440

20 (

3/4"

)

25 (1")

100 (4

"

)

350 (14

"

)

200946-1.p65

3/9/2004, 3:30 PM

5