516 01 3604 04

Specifications subject to change without notice.

29

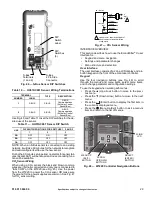

Fig. 46 — S-Bus Sensor DIP Switches

Use Fig. 46 and Table 11 to set the DIP switches for the de

-

sired use of the sensor.

NOTE: When an S-Bus sensor is connected to an existing

network, it will take 60 minutes for the network to recognize

and auto-configure itself to use the new sensor.

During the 60 minute setup period, no alarms for sensor fail

-

ures (except SAT) will be issued and no economizing func

-

tion will be available.

CO

2

Sensor Wiring

When using a CO

2

sensor the black and brown common

wires are internally connected and only one is connected to

“IAQ COM” on the W7220 (see Fig. 45). Use the power

from the W7220 to power the CO

2

sensor OR make sure

the ground for the power supplies are common. See Fig. 47

for CO

2

sensor wiring.

Fig. 47 — CO

2

Sensor Wiring

INTERFACE OVERVIEW

This section describes how to use the EconoMi$er

®

X user

interface for:

• Keypad and menu navigation

• Settings and parameter changes

• Menu structure and selection

User Interface

The user interface consists of a 2-line LCD display and a 4-

button keypad on the front of the economizer controller.

Keypad

Use the four navigation buttons (see Fig. 48) to scroll

through the menus and menu items, select menu items,

and to change parameter and configuration settings.

To use the keypad when working with menus:

• Press the ▲ (Up arrow) button to move to the previ

-

ous menu.

• Press the ▼ (Down arrow) button to move to the next

menu.

• Press the

(Enter) button to display the first item in

the currently displayed menu.

• Press the (Menu Up/Exit) button to exit a menu’s

item and return to the list of menus.

Fig. 48 — W7220 Controller Navigation Buttons

Table 10 — HH57AC081 Sensor Wiring Terminations

TERMINAL

TYPE

DESCRIPTION

NUMBER

LABEL

1

S-BUS

S-BUS

S-BUS

Communications

(Enthalpy Control

Sensor Bus)

2

S-BUS

S-BUS

S-BUS

Communications

(Enthalpy Control

Sensor Bus)

Table 11 — HH57AC081 Sensor DIP Switch

USE

DIP SWITCH POSITIONS FOR SWITCHES 1, 2, AND 3

1

2

3

DA

OFF

ON

OFF

RA

ON

OFF

OFF

OA

OFF

OFF

OFF

DIP

Switch

Label

DIP

Switches

(3)

S-Bus

2 Pin Side

Connector

S-Bus

Terminals

(1 and 2)

CO

2

SENSOR

24V

ANALOG

OUT

L1

(HOT)

L2

RED

BLACK

YELLOW

BROWN

ORANGE

GREEN

+

–

POWER SUPPLY. PROVIDE DISCONNECT

MEANS AND OVERLOAD PROTECTION

AS REQUIRED.

1

1

2 LINE

LCD

MENU UP

(EXIT)

BUTTON

SCROLL

UP/DOWN

BUTTONS

SELECT

(ENTER)

BUTTON