20

Specifications subject to change without notice.

516 01 3604 04

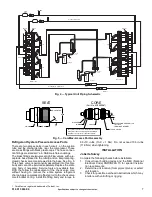

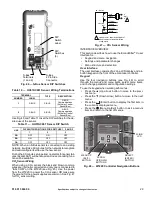

Fig. 34 — Typical Low-Voltage Control Connections

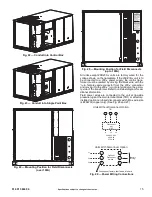

CENTRAL TERMINAL BOARD

The Central Terminal Board (CTB) is a pass through con

-

nection point. The CTB provides the capability to add facto

-

ry-installed options and field-installed accessories to the

units by cutting jumper wires without having to change or re

-

route wires through the structure of the unit. The CTB does

not provide any microprocessor control; it is simply a basic

multifunction wiring terminal configuration.

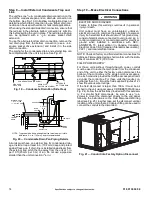

COMMERCIAL DEFROST CONTROL

The Commercial Defrost Control Board (DFB) coordinates

thermostat demands for supply fan control, 1 or 2 stage

cooling, 2 stage heating, emergency heating and defrost

control with unit operating sequences. The DFB also pro

-

vides an indoor fan off delay feature (user selectable). See

Fig. 35 for board arrangement.

The DFB is located in the RHH unit’s main control box (see

Fig. 2 and 36). All connections are factory-made through

harnesses to the unit’s CTB, to IFC (belt-drive motor) or to

ECM (direct-drive motor), reversing valve solenoids and to

defrost thermostats. Refer to Table 6 for details of DFB In

-

puts and Outputs.

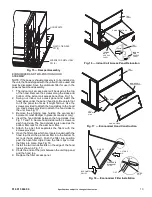

Fig. 35 — Defrost Control Board Arrangement

Reversing valve control

The DFB has two outputs for unit reversing valve control.

Operation of the reversing valves is based on internal logic;

this application does not use an “O” or “B” signal to deter

-

mine reversing valve position. Reversing valves are ener

-

gized during the cooling stages and the defrost cycle and

de-energized during heating cycles. Once energized at the

start of a cooling stage, the reversing valve will remain ener

-

gized until the next heating cycle demand is received. Once

de-energized at the start of a Heating cycle, the reversing

valves will remain de-energized until the next cooling stage

is initiated.

Compressor control

The DFB receives inputs indicating Stage 1 Cooling,

Stage 2 Cooling and Stage 1 Heating from the space ther

-

mostat or unit control system; it generates commands to

start compressors with or without reversing valve operation

to produce Stage 1 Cooling (one compressor runs), Stage 2

Cooling (both compressors run) or Stage 1 Heating (both

compressors run).

Auxiliary (Electric) Heat control

The RHH unit can be equipped with one or two auxiliary

electric heaters, to provide a second stage of heating. The

DFB will energize this Heating System for a Stage 2 Heating

Command (heaters operate concurrently with compres

-

sor(s) in the Stage 1 Heating cycle), for an Emergency

Heating sequence (compressors are off and only the elec

-

tric heaters are energized) and also during the Defrost cycle

(to eliminate a “cold blow” condition in the space).

X

C

G

W2

R

C

W2

G

W1

O/B/Y2

Y2

W1

R

Y1

Y1

Typical

Thermostat

Connections

T

H

E

R

M

O

S

T

A

T

(Note 1)

(Note 2)

1. Typical multi-function marking. Follow manufacturer’s configuration

instructions to select Y2. Do not configure for O output.

2. W2 connection not required on units without electric heating.

Field Wiring

Central

Terminal

Board

NOTES:

DIP

SWITCHES

SPEED-UP

JUMPERS