25

25

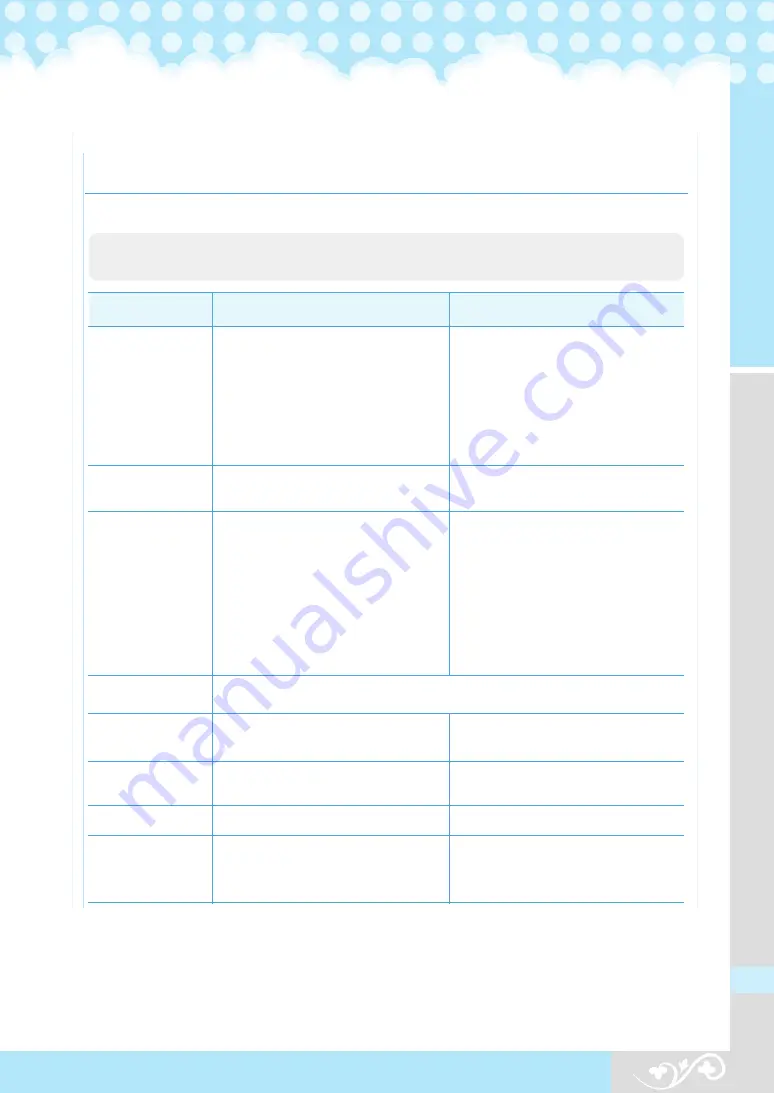

Before Calling Service

If the ice maker operation is not in good status, check the following items.

If the symptom still persists, contact the purchased site.

Operation Status

1. The ice maker does

not operate.

1. Power is supplied?

2. The power switch is turned off?

3. The supplied power is within

115

V

±

10%.

4. After power and water supply, the ice

detection sensor operates?

5. The ice damper is open?

6. The ambient temperature of the ice maker decreases.

7. The ice making level is appropriate?

8. The ice maker is contaminated?

1. The water supply valve is closed?

2. The water supply hose is properly installed?

3. The agency blocked water supply?

1. The water supply hose is closed?

2. Water is not supplied.

3. The compressor properly operates?

4. Ventilation is not properly done due to dust in

the filter on the front panel?

5. The fan motor in the condenser operates?

6. Is there any heat generator near the product?

7. The position of the drain hose is too low to supply enough water?

8. The ice made is too thin or thick?

9. The water in the water tank is not sufficient?

1. The ambient temperature of the installed place

is below 5

℃

?

2. The supplied water is insufficient?

1. The installed floor is not stable or weak to

stand the product?

1. Any foreign materials are in the drain hose?

1. Water is supplied into the water bowl?

1. Water flows into the ice box in some degree for ice flexibility. So it is not a failure.

2. While the ice maker operates, a little vibration can follow. It is not a failure.

1. Supply power.

2. Set the toggle switch to "ICE."

3. Check the power and use the dedicated outlet.

4. Remove ice.

5. Let the damper freely rotate for vertical movement.

6. The ambient temperature must be 5

℃

or above.

7. Adjust the plotter level.

8. Perform cleaning and sterilization.

1. Open the water supply valve.

2. Make correction after checking.

3. Wait for water supply from the agency.

1. Remove foreign materials in the water supply hose.

2. After checking the pump motor status, contact the

after-sales center.

3. After checking, contact the a qualified technician.

4. Remove dust from the filter on the front panel and

perform cleaning.

5. After checking, contact the a qualified technician.

6. Keep the product away from the heat generator.

7. Adjust the height of the drain hose.

8. Adjust the control bolt of the ice thickness sensor.

9. Adjust the plotter level.

1. Under 5

℃

or below, do not use the product.

2. When water is insufficient, supercooling may follow.

1. Adjust the floor level to be even.

1. Remove foreign materials in the drain hose.

1. After installation, provide water for initial operation.

2. After cleaning, provide water for operation.

3. To operate the product again after restoring water

block, provide water for operation.

2. Water is not supplied.

3. The ice maker

operates but ice is not

made well.

(Ice non-forming)

4. The following cases

are not failures.

5. The ice is too much

frozen.

6. Too big noise or

stange sound is heard.

7. Water is not drained

in the ice box.

8. The ice making is not

performed.

Check Item

Solution

■

Manufacturer :

www.icetro.com

78BL/ 3LT 2nd Namdong

Insdustrial Complex

Namdong-gu Incheon,

Korea

■

Sales Agency :

●Manufacture:

●Manufacture: