MFI2406LS

Page 20

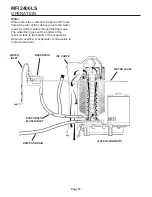

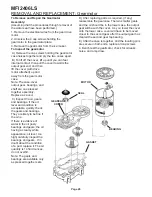

CONTROL SYSTEM DIAGNOSTICS

The control system consists of:

·

Control Board

·

Water Sensor

·

Ice Sensors

If the unit is OFF, check the

control board:

1. Is the Power OK light on? If not check power to

the unit. If it has power, and the Power OK light is

NOT on, check the high pressure and low pressure

cut outs. If they are both closed, replace the board.

If the Power OK light is ON, go to the next step.

2. Is the Water OK light on? If it is, go to the next

step. If not, check the water level in the reservoir. If

there is water in the reservoir, check that the water

sensor is plugged in. To check the

water sensor:

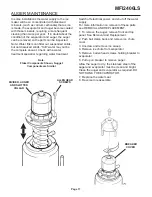

A. Unplug water sensor.

B. Pull water sensor from reservoir.

C. Place one ohmmeter lead on the sensor's plug

and the other on the sensor's tip. The meter should

show nearly zero resistance. If it reads infinite

resistance, check the tip for corrosion. If it is clean

and still reads open, replace the sensor.

OR connect a copper wire to the wire where the

water sensor plugs into and place the other end in

the water. The water OK light should go ON. If it

does not, replace the control board.

3.

Ice sensor check.

Is the Bin Full light Off? If it is

OFF and the Service light is Off, and the unit is not

running, replace the control board.

If it is OFF and the auger motor is running but the

compressor is not, check the compressor contactor

coil.

If it is on, the ice sensors may be blocked. Remove

them and check for mineral scale. Scotsman's test

box can also be used to determine if the ice sensors

or board are defective.

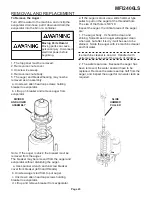

Using the tester:

A. Disconnect the ice sensors at the connection by

the ice chute. Connect the LED and PHOTO TRANS

wires to the control board's wires.

B. With the On - Off (mode) switch in either position,

move the Bin Full switch on the tester to Bin Full -

the tester's light will blink and after a few seconds

the bin full light on the control board will come on. If

not, replace the board.

Move the Bin switch on the tester to Bin Empty. The

light on the tester will go out, and after a few

seconds the Bin Full light on the board will go out. If

master switch is ON, the unit should start.

Содержание MFI2406LS Series

Страница 29: ...MFI Series Wiring Diagram 2406LS Page 27...