Updating the firmware with the Ethernet port - Service only

Note: The drive uses a limited version of FTP protocol to communicate on the Ethernet interface. Use a simple, command-line FTP session, such as the DOS command

line, to communicate with the drive.

1. Obtain the current drive firmware from the web.

2. Connect an Ethernet patch cable to the drive's Ethernet interface and to a computer. To meet electromagnetic immunity requirements, a shielded Ethernet cable is

required.

3. Create an FTP session between the drive and the computer. The drive 's IP address: 169.254.0.3

4. At the user prompt, type

guest

and press Enter.

5. At the password prompt, press Enter. No response is needed.

6. Type

bin

to set the communication mode to binary.

7. Type

put <firmware name>

to transfer the firmware to the drive. Replace

<firmware name>

with the actual firmware name. The drive resets automatically

when the transfer is complete and the FTP session closes.

8. After the drive resets, the new firmware is loaded on the drive.

9. Remove the Ethernet patch cable from the drive's Ethernet interface and the computer.

Maintenance functions

Refer to this section for information on diagnosing and maintaining your tape drives.

The drive can:

Run diagnostics

Test write and read functions

Test a suspect tape cartridge

Update firmware

Complete other diagnostic and maintenance functions

The drive must be in Maintenance mode to complete these functions.

Attention: Maintenance functions cannot be run concurrently with read or write operations. While in maintenance mode, the tape drive does not accept host interface

commands from the server. The tape drive does accept LDI or RS-422 commands.

describes each diagnostic and maintenance function that the drive can complete, gives the function code that appears on the Single-character Display (SCD), and

directs you to the instructions for completing the function. Use a customer-supplied scratch (blank) data cartridge for diagnostic testing. The diagnostic and maintenance

functions are not supported on the WORM and partitioned data tape cartridges.

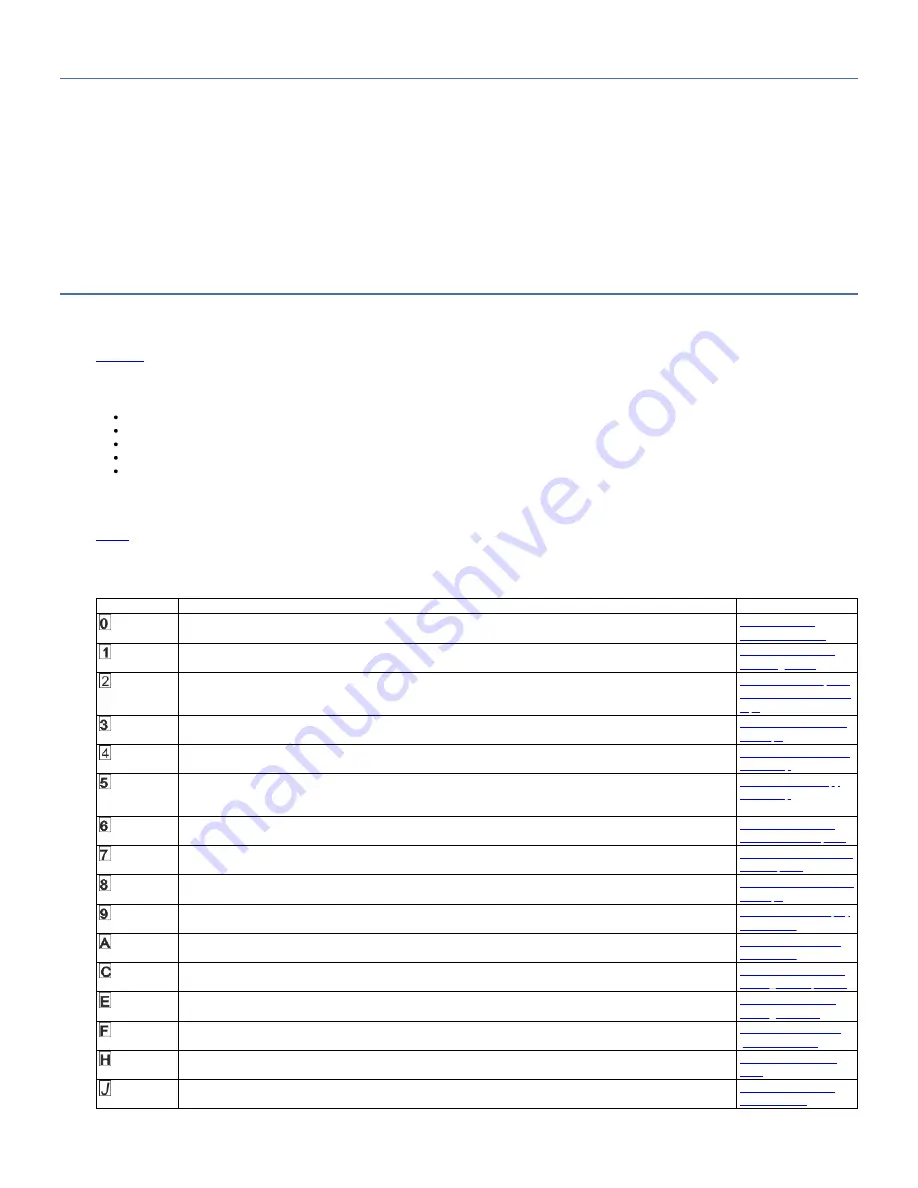

Table 1. Diagnostic and maintenance functions

Function Code

Diagnostic or Maintenance Function

Instructions Location

Exit Maintenance Mode: Causes the drive to become available for reading and writing data.

Function code 0:

Maintenance mode

Run Drive Diagnostics: Runs tests to determine whether the drive can properly load and unload cartridges, and read and

write data.

Function code 1: Run

drive diagnostics

Update Tape Drive Firmware from FMR Tape: Loads updated firmware from a field microcode replacement (FMR) tape.

Function code 2: Update

drive firmware from FMR

tape

Create FMR Tape: Copies its field microcode replacement (FMR) data to a customer-supplied scratch (blank) data cartridge.

Function code 3: Create

FMR tape

Force a Drive Dump: Completes a memory dump of data (also known as saving a microcode trace).

Function code 4: Force a

drive dump

Copy Drive Dump: Copies data from a drive memory dump (captured by using Function Code 4) to the beginning of a

customer-supplied scratch (blank) data cartridge, copies a drive memory dump to flash memory, or erases a memory dump

from flash memory.

Function code 5: Copy

drive dump

Run Host Interface Wrap Test: Checks the circuitry from and to the connector.

Function code 6: Run

host interface wrap test

Run RS-422 Wrap Test: This test causes the drive to run a check of the circuitry and connector for the RS-422 interface.

Function code 7: Run RS-

422 wrap test

Unmake FMR Tape: Erases the FMR data on a customer-supplied scratch (blank) data cartridge and rewrite the cartridge

memory on the tape. This action turns the cartridge into a valid customer-supplied scratch data cartridge.

Function code 8: Unmake

FMR tape

Display Error Code Log: Displays the last 10 error codes, one at a time (the codes are ordered; the most recent is presented

first and the oldest 10th) is presented last).

Function code 9: Display

error code log

Clear Error Code Log: Erases the contents of the error code log.

Function code A: Clear

error code log

Insert Cartridge into Tape Drive: This function cannot be selected by itself, but is a part of other maintenance functions

(such as Run Tape Drive Diagnostics and Create FMR Tape) that require a tape cartridge to be loaded.

Function code C: Insert

cartridge into tape drive

Test Cartridge & Media: Completes tests to ensure that a suspect cartridge and its magnetic tape are acceptable.

Function code E: Test

cartridge & media

Write Performance Test: Completes tests to ensure that the drive can read from and write to tape.

Function code F: Write

performance test

Test Head: Completes tests to ensure that the tape drive's head and tape-carriage mechanics are working correctly.

Fast Read/Write Test: Completes tests to ensure that the drive can read from and write to tape.

Function code J: Fast

read/write test

IBM TS22xx - TS2290, TS2280, and TS2270

93

Содержание TS2290

Страница 1: ...IBM TS22xx TS2290 TS2280 and TS2270 IBM...