INSTALLATION AND OPERATION INSTRUCTIONS

8

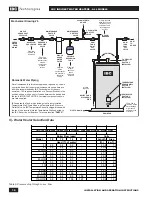

IBC INDIRECT WATER HEATERS - ALL MODELS

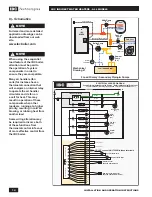

3) - Piping

A. Domestic water piping - See Section 8, Mechanical Drawing # 6

1. Drain the domestic water system.

• Shut off the cold water supply at the main shutoff valve.

• Open one or more faucets to relieve the pressure. Open the system drain,

leaving the faucets open.

2. Position the water heater in the final location.

3. Connect the cold water supply piping.

• Install piping onto cold inlet connection -

• Connect to cold water supply connection using the following suggested

components where applicable: A union, a heat trap, a shut-off valve, an

expansion tank, a back flow preventer, a vacuum breaker and a filter

(recommended to prevent sediment buildup).

4. Connect the domestic hot water piping.

• Install piping on to hot water supply connection using a union, a heat trap,

and a shut-off valve.

• Pipe the relief valve discharge so that the discharge from the valve will exit

only within 6 inches above, or at any distance below, the structural floor, and

cannot contact any live electrical part. The discharge opening must not be

blocked or reduced in size under any circumstances.

5. Fill the water heater tank.

• Open all faucets to allow air to purge from the tank and piping. Remove

screens on faucets.

• Open the domestic hot water shut-off valve.

• Slowly open the cold water inlet shut-off valve.

• Purge all of the air from the domestic water system. Allow water to run so the

tank is completely purged of any debris. Run the water long enough so that it

runs clear and to change at least one tank volume change past full. Close all

faucets. Reinstall all of the screens in the faucets.

• Check the system for leaks. Repair as required.

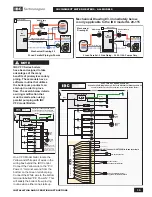

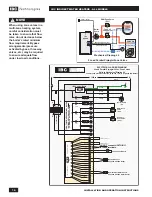

B. Boiler water piping. See Figures in Section 8.

1. Determine where the boiler, the space heating, and the water heater

connections should be made based on the type of piping system that is either

in place, or is to be installed for a new hydronic system installation. See

Schematic drawings in Section 8 for direction.

2. It is recommended that minimum size 1” pipe be used on the water heater

zone to ensure adequate flow, larger sizes (80 and 115 models) min 1 1/4”.

Zone Circulator System

For space heating systems that use Zone Circulators only;

refer to Mechanical

Drawings #1, #2 and #3 in Section 8 of this manual.

The water heater connection

labeled “BOILER SUPPLY” should be piped to the boiler supply piping after

the air purger and before the space heating takeoffs - for primary/secondary

systems,

see Mechanical Drawing #1

- parallel piping,

see Mechanical drawings

#2 and #3.

Mount the water heater circulator as close as is practicable to the

water heater, and make sure the flow arrow points toward the water heater. The

use of shut-off valves is recommended for future service convenience.

NOTE

Installers should inquire of

local water purveyors as to

the suitability of their supply

for use in hydronic heating

systems.

If water quality is questionable,

a local water treatment expert

must be consulted for testing,

assessment and, if required,

treatment.

Alternatively, water or hydronic

fluid of known quality can be

brought to the site.

WARNING

Do not use automotive-type

ethylene or other types of

automotive glycol antifreeze,

or undiluted antifreeze

of any kind on the boiler

water side of the system.

This may result in severe

boiler or tank damage. It

is the responsibility of the

Installer to ensure that glycol

solutions are formulated to

inhibit corrosion in hydronic

heating systems of mixed

materials. Improper mixtures

and chemical additives may

cause damage to ferrous and

non-ferrous components as

well as non-metallic, wetted

components, normally found

in hydronic systems.

Ethylene glycol is toxic, and

may be prohibited for use

by codes applicable to your

installation location. For

environmental and toxicity

reasons, IBC recommends

only using non-toxic

propylene glycol, and non-

toxic boiler water additives of

any kind.