7

INSTALLATION AND OPERATION INSTRUCTIONS

IBC INDIRECT WATER HEATERS - ALL MODELS

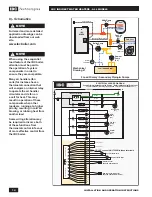

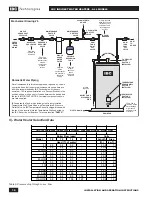

D. Additional recommended components

1. Shut-off valves. Allows the isolation of the water heater from the boiler

system during service.

2. Unions. Allows for easy locating or removal.

3. Vacuum breaker. Protects the water heater from collapse if a hot tank is

valved off to service other components in the system.

4. Thermal expansion tank. If the water heater is installed in a closed water

supply system, such as a system having a back flow preventer in the cold

water supply line, the installation of a thermal expansion tank is required.

5. Refer to drawing #6 in this manual for suggested external components.

E. Removing the Existing Domestic Water Heating System

If the IBC water heater is being installed in an older hydronic system that does

not use an IBC boiler:

• External Tankless Heater - Disconnect all lines to the boiler and plug the

boiler fittings. Disconnect the external heater from the boiler piping, and the

domestic piping systems.

• Internal Tankless Heaters - Disconnect the domestic piping. Do not plug the

cold water or the hot water fittings in the internal tankless coil. Leave the coil

in the boiler with the cold and hot water fittings open to prevent pressure

build-up in the coil.

If the IBC water heater is being installed to replace an electric or direct fired

gas or oil water heater: Disconnect the water piping and either strip back to

the nearest main line and cap off, or re-use for the new tank, whichever is

appropriate.

• Electric Water Heater - Disconnect the electrical supply wiring and remove

back to the breaker panel or terminate in an approved junction box. Work

must conform to all applicable electrical codes.

• Direct Fired Gas Water Heater - Disconnect the gas supply line to the heater,

strip back to the nearest mains piping and cap off. Remove vent connector

back to the common venting system and seal off or abandon as applicable.

Work must conform to all applicable codes.

• Direct Fired Oil Water Heater - Disconnect the oil supply line to the heater,

strip back to the tank or nearest mains piping and cap off. If oil heating

system is to be abandoned completely, ensure proper removal and disposal

of old oil tank and remaining fuel oil. Remove vent connector back to the

common venting system and seal off or abandon as applicable. Work must

conform to all applicable codes.

F. Water Quality

Improper water quality will reduce the expected life of the water heater. Hard

water, sediment, high or low Ph, and high levels of chlorides in the domestic

water should be avoided. Sediment and hard water will eventually coat the

heating coil inside the water heater and reduce the rate of hot water production

and may, eventually cause a failure. High or low Ph and/or high chloride

concentrations will cause corrosion and eventually failure. A filter is strongly

recommended where sediment is present in the water. A water softening system

is recommended for areas with hard water.

In an area where the water quality is not known, a water quality test should be

performed.

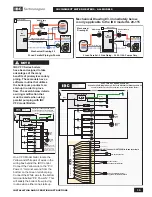

CAUTION

Do not operate the IBC water

heaters in areas where the

Ph is above 8.0 or below

6.0, and/or with chloride

concentrations greater than

80 parts per million (ppm).

IBC’s standard warranty does

not cover problems caused

by improper water Ph or

excessive levels of chlorides.

WARNING

There are a number of

conditions, including

improper control settings,

which could result in elevated

tank temperatures from

ANY type of water heater.

An overheating hazard can

result, potentially causing

serious personal injury and/or

property damage.

IBC Highly recommends

as a minimum precaution,

the installation of a point of

source ASSE 1017 approved

thermostatic mixing valve on

the outlet of the water heater.

Local jurisdictions may

require more comprehensive

protective measures

depending on the place of

installation (ie. schools,

nursing homes, etc.). Check

with local Authorities for

direction.

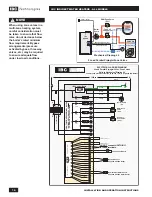

CAUTION

When removing any fuel

burning appliance from a

common venting system, the

opening must be properly

sealed off and; if there are

remaining appliances still

using the common venting

system, the vent must be

examined to ensure that it is

not over-sized as a result of

having removed the old water

heater.