AS14100MP-CL

Page

16

The ideal location for the unit is above and not more

than 6.1m (20ft) from the drain. For such installations,

using the appropriate adaptor fitting (supplied),

connect 20mm (3/4”) plastic tubing to the drain line

connection located on the top of the valve.

If the unit is located more than 6.1m (20ft) from the

drain, use 25mm tubing for runs up to 12.0m. You

may elevate the line up to 1.8m providing the run

does not exceed 4.5m and the water pressure at the

conditioner is not less than 280kPa (40psi.) You may

elevate an additional 500mm for each additional

70kPa. (10psi) of water pressure.

When the drain line is elevated and empties into a

drain which is below the level of the control valve,

form a 170mm (7 inch ) loop at the drain end of the

line so that the bottom of the loop is level with the

drain line connection. This provides an adequate

siphon trap.

If the drain empties into an overhead sewer line, a

sink-type trap must be used.

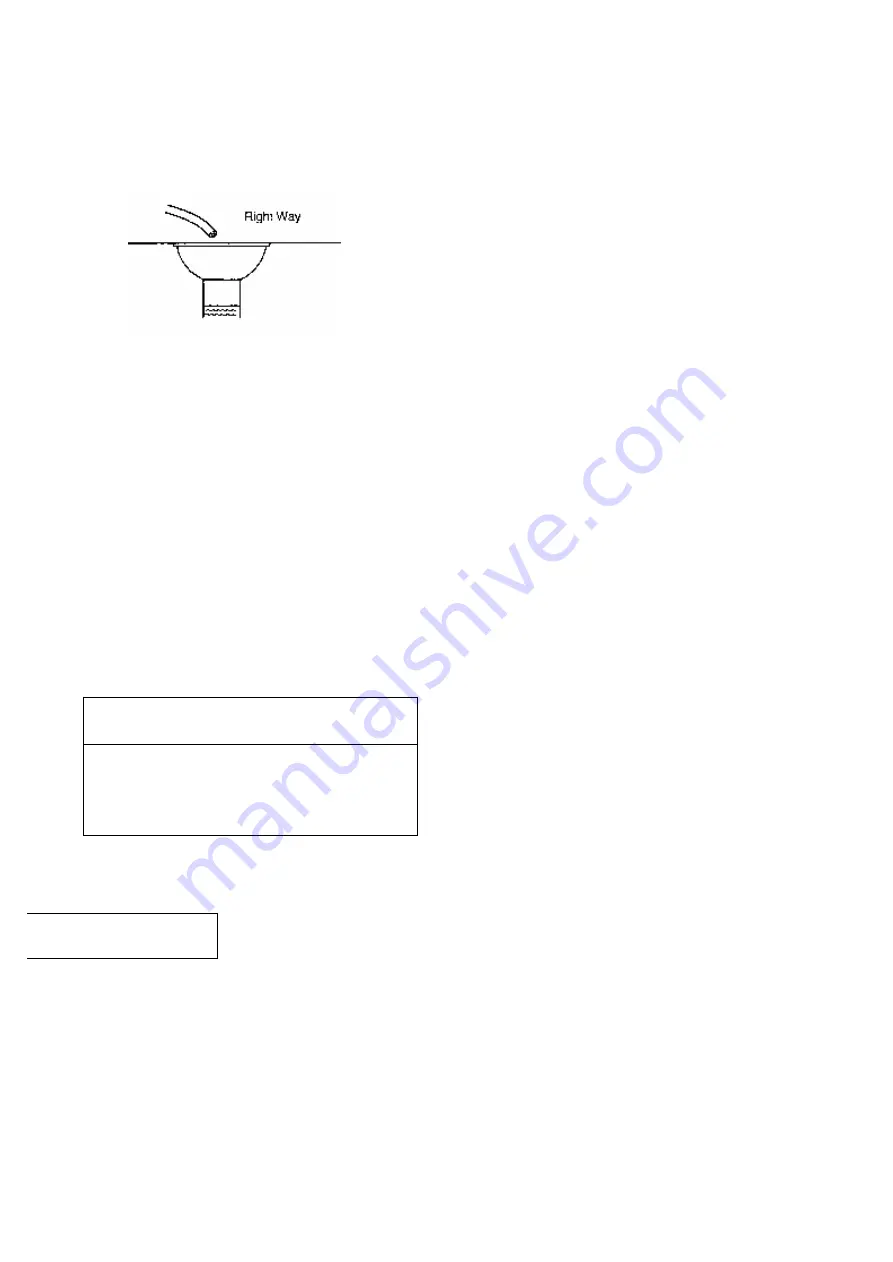

Caution

Never connect the drain line into a drain,

sewer line or trap. Always allow an air gap

between the drain line and the wastewater

to prevent the possibility of sewage being

back-siphoned into the conditioner.

Important Installation Details

The control valve, fittings and/or bypass are designed

to accommodate minor plumbing misalignments but

are not designed to support the weight of the system

or the plumbing.

Do no use Vaseline, oils, other hydrocarbon lubricants

or spray silicone anywhere. A silicone lubricant may

be used on black o-rings but is not necessary.

Avoid

any type of lubricants, including silicone, on the

clear lip seals.

The nuts and caps are designed to be unscrewed or

tightened by hand or with the special plastic wrench.

Do not use a pipe wrench to tighten or loosen nuts or

caps. Do not place a screwdriver in the slots on caps

and/or tap with a hammer.

Do not use pipe dope or other sealant on threads.

Use teflon tape on threaded inlet, outlet and drain

fittings.Teflon tape is not necessary on the nut

connection or caps because of o-ring seals.

After completing any valve maintenance involving

the drive assembly of the drive camp assembly

and pistons, press and hold NEXT and REGEN

buttons for 3 seconds or unplug power source

jack from the printed circuit board (black wire)

and plug back in

. This resets the electronics and

establishes the service piston position. The display

should flash all wording, then flash the software

version and then reset the valve to the service

position.

All plumbing should be done in accordance with local

plumbing codes. The pipe size for the drain line

should be a minimum of 20mm.

Solder joints near the drain must be done prior to

connecting the drain line flow control fitting. Leave at

least 150mm (6”) between the drain line control fitting

and solder joints when soldering pipes that are

connected on the drain line control fitting. Failure to

do this could cause interior damage to the drain line

flow control fitting.

When assembling the installation fitting package (inlet

and outlet), connect the fitting to the plumbing system

first and then attach the nut, split ring and o-ring.

Heat from soldering or solvent cements may damage

the nut, split ring and o-ring. Solder joints should be

cool and solvent cements should be set before

installing the nut, split ring or o-ring. Avoid getting

primer and solvent cement on any part of the o-rings,

bypass valve or control valve.

Position the softener within 1 ½ metres of a 10 amp

GPO. The transformer is connected into the plug

socket on the back of the valve control panel. Do not

Figure 5 - Air Gap Installation

Not In Bypass In Bypass

Содержание AS14100MP-CL

Страница 3: ...AS14100MP CL Page 3...

Страница 10: ...AS14100MP CL Page 10 MODEL AS14100MP WATER SOFTENER WITH CONTROL VALVE SERIES MODEL WS1EI...

Страница 18: ...AS14100MP CL Page 18...

Страница 19: ...AS14100MP CL Page 19 WS1EI Screen Display Information And Programming Instructions...

Страница 21: ...AS14100MP CL Page 21 General Regeneration Error Screens Status...

Страница 28: ...AS14100MP CL Page 28 SPARE PARTS AND SERVICING INSTRUCTIONS...

Страница 37: ...AS14100MP CL Page 37 10 V3156 O ring 214 2 Flow Diagrams Service and Backwash flow diagram service...

Страница 38: ...AS14100MP CL Page 38 flow diagram backwash Flow Diagram Downflow...

Страница 39: ...AS14100MP CL Page 39 flow diagram downflow brine Flow Diagrams Rinse and Fill...

Страница 40: ...AS14100MP CL Page 40 flow diagram rinse flow diagram fill WS1 Wrench Order No V3193 01...

Страница 48: ...AS14100MP CL Page 48 INJECTOR PERFORMANCE CURVES...

Страница 49: ...AS14100MP CL Page 49...

Страница 51: ...AS14100MP CL Page 51...