8

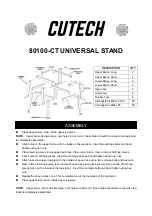

Step 3:

Install the riser covers or optional Riser Electrical Panels using (8) # 8 x .375 self-threading

screws. Align the riser covers holes with the holes in the riser box and thread #8 x .375

screws into each hole. Tighten at this time. For optional Riser

Electrical Panels install 1.5”

plastic bushing into the holes located in the rear of the riser boxes. Then run the power

cord(s) from the inside of the riser bo

x through the 1.5” plastic bushing. Align the Riser

Electrical Panel holes with the holes in the riser box and thread #8 x .375 screws into each

hole. Tighten at this time. Install plastic caps where needed

.

Note: For SESIS Panels

CAUTION: Risk of Electric Shock. Do NOT plug into another

Relocatable power tap.

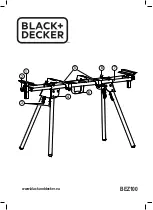

STEP 4

Carefully turn instrument shelf over and from the backside of the bench align the U shaped flanges at the

bottom of the riser boxes with the bench worksurface. Carefully slide the U shaped flanges over the

worksurface until the back of the riser box is approximately 1/8” from the back of the worksurface. Look under

the worksurface to align the slots in the U shaped flanges with the inserts in the worksurface. When both riser

boxes are aligned with the inserts attach them with 1/4-

20 x .75 hex head bolts and 1/4” flat washers as

shown. Tighten hardware at this time.