9

−

3

111

Cutting speed and choice of tools

Choice of blade

When using band saws to cut metals, an important factor is the choice of pitch,

i.e. the number of teeth per inch (25.4 mm.), which must be suitable for the

workpiece material. The following recommendations may be taken as general

guidelines:

thin-walled materials, such as sheet steel, tubes and profiles require a fine

pitch frequency 3 to 6 teeth should be engaged in the breadth of the material

at any one time;

large section cutting requires a coarse pitch to cope with the higher volume of

swarf and optimal tooth penetration;

soft materials (aluminium alloys, soft bronze etc.) also require a coarse tooth

pitch.

Saw tooth pitch

The choice of teeth per inch, therefore, depends on various factors:

the size of the section;

the hardness of the material;

workpiece wall breadth.

Very large dimensions require coarse teeth, while small dimensions require finer

teeth. Whatever the case, ensure that there are always at least six teeth engaged

in the cut, with reference to the thinnest vertical walls positioned transversally to

the blade.

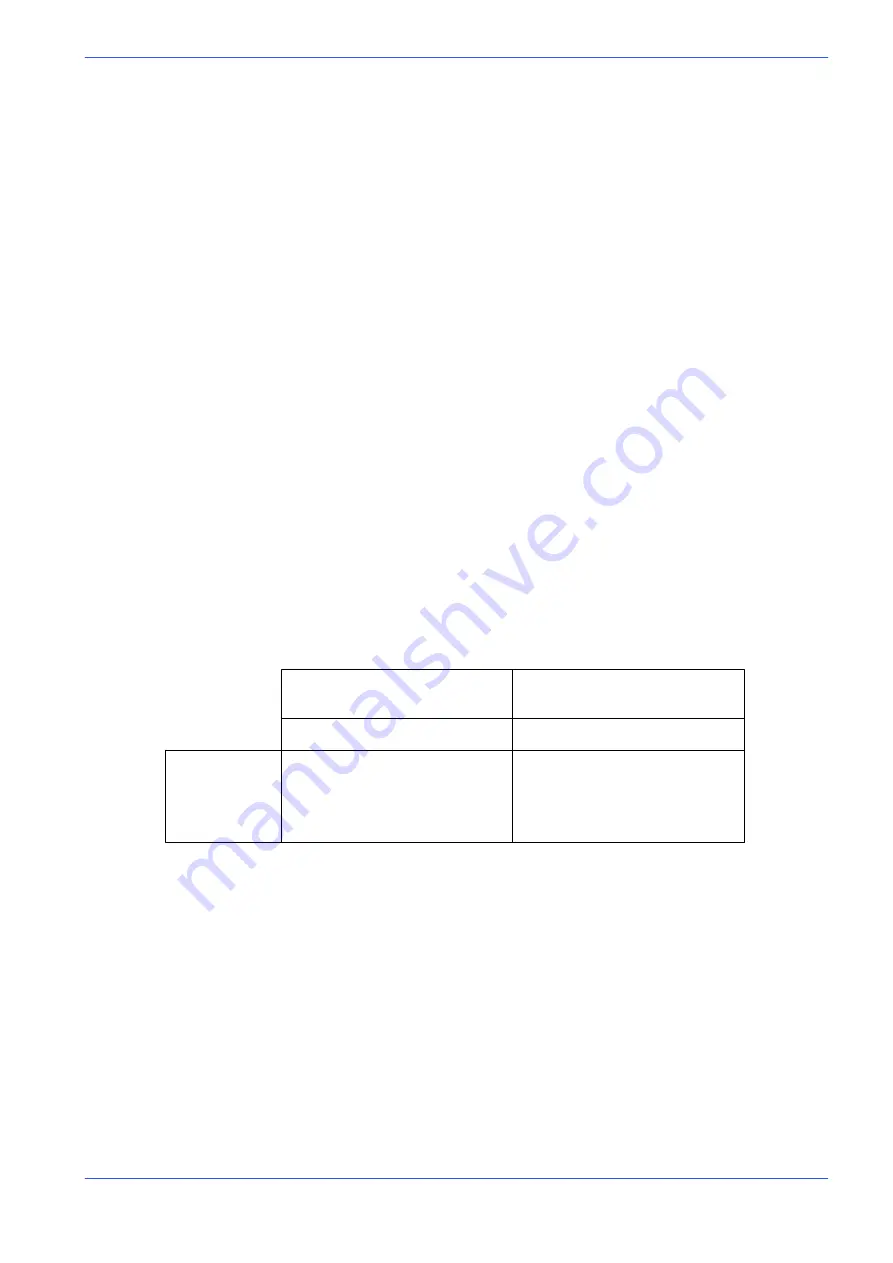

Concerning the type of Shark machine, a first broad distinction can be made

according to the hardness of materials:

< 61 HRB

> 65 HRB

< 55 kg/mm

2

> 65 kg/mm

2

3 / 4

4 / 6

8 / 12

5 / 8

6 / 10

10 / 14

Mild steels

MINIMUM

OPTIMUM

MAXIMUM

Hard steels

NR. TEETH/INCH

NR. TEETH/INCH

Содержание DM-1215

Страница 1: ...USE AND MAINTENANCE MANUAL YEAR OF MANUFACTURE ______________ DM 1215 EN ...

Страница 2: ......

Страница 4: ......

Страница 34: ......

Страница 53: ...6 7 52 Diagrams exploded views and replace Standardised Wiring Diagrams ...

Страница 54: ...6 8 53 Use and maintenance manual DM 1215 ...

Страница 55: ...6 9 54 Diagrams exploded views and replace ...

Страница 56: ...6 10 55 Use and maintenance manual DM 1215 F6 F7 F8 F3 F4 F5 RT4 ...

Страница 57: ...6 11 56 Diagrams exploded views and replace F1 F2 F9 ...

Страница 58: ...6 12 57 Use and maintenance manual DM 1215 S4 KSTO S8 S4 K01 ...

Страница 59: ...6 13 58 Diagrams exploded views and replace KSTO KSTO RT4 ...

Страница 60: ...6 14 59 Use and maintenance manual DM 1215 F10 F11 HL1 GD1 F12 HL2 SL1 SL1 F13 SLM YV1 S V SPRAY MIST SYSTEM ...

Страница 61: ...6 15 60 Diagrams exploded views and replace ...

Страница 62: ...6 16 61 Use and maintenance manual DM 1215 ...

Страница 63: ...6 17 62 Diagrams exploded views and replace ...

Страница 64: ...6 18 63 Use and maintenance manual DM 1215 ...

Страница 65: ...6 19 64 Diagrams exploded views and replace ...

Страница 66: ...6 20 65 Use and maintenance manual DM 1215 ...

Страница 67: ...6 21 66 Diagrams exploded views and replace ...

Страница 68: ...6 22 67 Use and maintenance manual DM 1215 ...

Страница 69: ...6 23 68 Diagrams exploded views and replace ...

Страница 70: ...6 24 69 Use and maintenance manual DM 1215 ...

Страница 71: ...6 25 70 Front flywheel assembly ...

Страница 74: ...6 28 73 Use and maintenance manual DM 1215 Motor flywheel assembly ...

Страница 77: ...6 31 76 Cutting head cover ...

Страница 79: ...6 33 78 Vice assembly ...

Страница 81: ...6 35 80 Base assembly ...

Страница 83: ...6 37 82 Control panel ...

Страница 85: ...6 39 84 Fixed work table and turntable ...

Страница 88: ...6 42 87 Use and maintenance manual DM 1215 Cylinder unit ...

Страница 90: ...6 44 89 Use and maintenance manual DM 1215 Laser and lamp group ...

Страница 92: ......

Страница 132: ......

Страница 136: ......