6

F R O N T S U S P E N S IO N

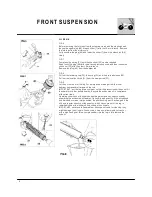

L e t s se e w h a t h a p p e n s in e a ch le g d u rin g R E B O U N D .

S p rin g re b o u n d a ctio n p u sh e s th e sta n ch io n d o w n w a rd s, th u s ca u sin g a n o il

n e e d in to th e ca rtrid g e (se e F IG . 4 ).

T h e co m p re ssio n o f th e o il vo lu m e in to th e ch a m b e r o ve r th e p u m p in g e le m e n t

(1 0 ) p u sh e s th e w a sh e rs (B ) a t th e p u m p in g e le m e n t p isto n b o tto m to o p e n . T o

ch a n g e th e fo rk d a m p in g n o w , th e w a sh e r se ttin g (B ) ca n b e ch a n g e d , a s

d e scrib e fo r th e p isto n (4 ).

A p a rt fro m flo w in g th ro u g h th e a b o ve p a ssa g e , th e o il is p u sh e d in to th e ro d (9 )

a n d ca n flo w o u t o f th e ch a m b e r a t th e p u m p in g e le m e n t b o tto m th ro u g h th e

a re a o u tlin e d b y th e p o sitio n o f th e co n ica l p in (1 3 ). T h e size o f th is a re a ca n b e

ch a n g e d b y tu rn in g th e re b o u n d s cre w a d ju ste r (1 1 ). T h e ch a m b e r a t th e

p u m p in g e le m e n t b o tto m is a lso fille d w ith th e o il flo w in g th ro u g h th e p isto n

slo ts (4 ). T h e o il flo w w in s o ve r th e a ctio n o f th e re tu rn sp rin g (2 1 ) a n d lifts th e

w a sh e r (2 2 ), th u s a llo w in g th e o il to flo w fro m th e o u te r ch a m b e r in to th e b o d y

in n e r ch a m b e r. (6 ).

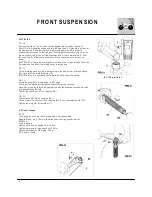

G E N E R A L R U L E S F O R A P R O P E R O V E R H A U L IN G

1 . A fte r a to ta l d isa sse m b ly, a lw a ys u se n e w se a ls d u rin g th e re a sse m b ly sta g e .

2 . A lw a ys fo llo w th e se q u e n ce 1 -2 -1 w h e n tig h te n in g tw o scre w s o r n u ts clo se

o n e to e a ch o th e r, i.e . a lw a ys tig h te n th e first scre w (1 ) a fte r tig h te n in g th e

se co n d scre w (2 ).

3 . U se n o n -in fla m m a b le a n d p o s sib ly b io d e g ra d a b le so lve n t w h e n cle a n in g .

4 . A lw a ys lu b rica te a ll p a rts in re la tive co n ta ct w ith fo rk o il b e fo re re a sse m b lin g .

5 . A lw a ys g re a se th e o il se a l lip s be fo re re a sse m b lin g .

6 . U se o n ly m e tric w re n ch e s a n d n o t in ch w re n ch e s. In ch w re n ch e s co u ld h a ve

size s, w h ich a re sim ila r to m illim e te r w re n ch e s b u t co u ld d a m a g e th e scre w s,

th u s

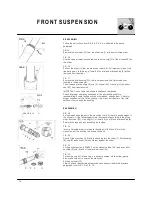

T R O U B L E

C A U S E

R E M E D IE S

O il le a ka g e fro m th e o il se a l

1 . O il se a l w e a r

1 . C h a n g e o il se a l

2 . S co re d sta n ch io n tu b e

2 . C h a n g e th e tu b e a n d th e o il se a l

3 . D irty se a l

3 . C le a n o r re p la ce

F o o t o il le a ka g e

1 . F o o t va lve O R d a m a g e d

1 . C h a n g e th e se a l

2 . L o o se fo o t va lve

2 . T ig h te n th e sc re w

3 . O R o f th e co m p re ssio n scre w

3 . C h a n g e th e se a l

4 . A d ju ste r d a m a g e d

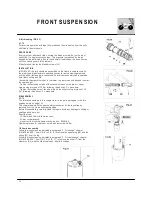

T h e fo rk is to o so ft u n d e r a n y a d ju st-

m e n t co n d itio n s

1 . L o w o il le ve l

1 . T o p u p

2 . B ro ke n sp rin g

2 . C h a n g e th e sp rin g

3 . T o o lo w o il visco sity

3 . U se a d iffe re n t o il visco sity

T h e fo rk is to o h a rd u n d e r a n y a d ju st-

m e n t co n d itio n s

1 . T o o h ig h o il le ve l

1 . R e sto re th e o il le ve l

2 . T o o h ig h o il visco sity

2 . U se a d iffe re n t o il visco sity

T h e fo rk h a s n o re a ctio n s w h e n a d ju st-

m e n t ch a n g e s a re m a d e

1 . In n e r ro d p in b lo cke d

1 . C le a n o r ch a n g e th e ro d

2 . B lo cke d co m p re ssio n

2 . D isa sse m b le a n d cle a n

3 . S cre w a d ju ste r

4 . O il w ith fo re ig n b o d ie s

4 . C le a n a n d ch a n g e o il

5 . F o re ig n b o d ie s

5 . D isa sse m b le a n d cle a n

6 . O cclu d in g d a m p e r va lve s

D e cre a se d le g stiffn e ss

S lid in g b u sh in g w e a r

C h a n g e slid in g b u sh in g

Содержание SM 610 2006

Страница 1: ...1 W orkshop Manual SM 610 TE 610 2006 Part N 8000 A4640 04 2005 ...

Страница 4: ...4 W here not otherwise specified data and instructions refer to all m odels SM 610 TE 610 ...

Страница 6: ...6 ...

Страница 7: ...1 GENERAL Section ...

Страница 15: ...1 Section MAINTENANCE ...

Страница 19: ...1 TROUBLESHOOTING Section ...

Страница 25: ...1 SETTINGS AND ADJUSTMENTS Section ...

Страница 41: ...1 GENERAL OPERATIONS Section ...

Страница 53: ...1 ENGINE DISASSEMBLY Section ...

Страница 74: ...22 ...

Страница 75: ...1 ENGINE OVERHAULING Section ...

Страница 100: ...26 ...

Страница 101: ...1 ENGINE REASSEMBLY Section ...

Страница 106: ...6 ENGINE REASSEMBLY ...

Страница 110: ...10 ENGINE REASSEMBLY A 28m m 1 1 in M AIN SHAFT B 25m m 0 98 in AUXILIARY SHAFT ...

Страница 129: ...1 FRONT SUSPENSION Section ...

Страница 144: ...16 ...

Страница 145: ...1 REAR SUSPENSION Section ...

Страница 153: ...9 REAR SUSPENSION ...

Страница 158: ...14 REAR SUSPENSION L 234 5 237 5 m m 9 23 9 35 in ...

Страница 163: ...1 BRAKES Section ...

Страница 171: ...9 BRAKES Periodically check the connecting hoses A and B if the hoses are worn or cracked their replacem ent is advised ...

Страница 172: ...10 ...

Страница 173: ...1 ELECTRIC SYSTEM Section ...

Страница 176: ...4 ELECTRIC SYSTEM ...

Страница 179: ...7 ELECTRIC SYSTEM ...

Страница 197: ...25 ELECTRIC SYSTEM Fig 1 Fig 2 Fig 3 Fig 4 Fig 5 Fig 1 Fig 7 Fig 8 Fig 9 Fig 10 Fig 6 Fig 12 Fig 11 ...

Страница 202: ...30 ELECTRIC SYSTEM TE SM L H COM M UTATOR ...

Страница 205: ...1 ENGINE COOLING SYSTEM Section ...

Страница 208: ...4 ...

Страница 209: ...1 LUBRICATION CIRCUIT Section ...

Страница 211: ...1 SPECIFIC TOOLS Section ...

Страница 219: ...1 FRAME AND W HEELS Section ...

Страница 229: ...1 NOTES FOR USA CDN AUS MODELS Section ...