Contents

Introduction..................................................................... 6

Safety..............................................................................7

Assembly...................................................................... 12

Operation...................................................................... 12

Maintenance................................................................. 14

Troubleshooting............................................................ 15

Transportation and storage...........................................16

Technical data.............................................................. 17

Accessories.................................................................. 19

Service..........................................................................19

Registered trademarks................................................. 20

Introduction

Owner responsibility

WARNING: Processing of concrete and

stone by methods such as cutting, grinding

or drilling, especially during dry operation,

generates dust that comes from the material

being processed, which frequently contains

silica. Silica is a basic component of sand,

quartz, brick clay, granite and numerous

other minerals and rocks. Exposure to

excessive amount of such dust can cause:

Respiratory disease (affecting your ability to

breathe), including chronic bronchitis,

silicosis and pulmonary fibrosis from

exposure to silica. These diseases may be

fatal;

Skin irritation and rash.

Cancer according to NTP* and IARC* */

National Toxicology Program, International

Agency for Research on Cancer.

Take precautionary steps:

Avoid inhalation of and skin contact with

dust, mist and fumes.

Wear and ensure that all bystanders wear

appropriate respiratory protection such as

dust masks designed to filter out

microscopic particles. (See OSHA 29 CFR

Part 1926.1153)

To minimize dust emissions, use water to

bind the dust, when feasible. If dry operation

is necessary, use an appropriate dust

extractor.

It is the owner’s/employer’s responsibility that the

operator has sufficient knowledge about how to use the

product safely. Supervisors and operators must have

read and understood the Operator’s Manual. They must

be aware of:

• The product’s safety instructions.

• The product’s range of applications and limitations.

• How the product is to be used and maintained.

National/Local regulations could restrict the use of this

product. Find out what regulations are applicable where

you work before you start using the product.

Product description

This Husqvarna Drill Motor is a transportable diamond

core drill to be used with an approved drill stand.

The diamond drill bit is a hollow drill that has diamond

segments. Water goes through the ball valve, hose and

the diamond drill bit. The water flushes the drilled

material out off the slot and decreases the temperature

in the drill bit.

This product has Smartstart

™

. Refer to

To use

Smartstart

™

on page 13

.

Some models of this product have embedded

connectivity. Refer to

Embedded connectivity on page

6

.

Embedded connectivity

The cloud asset management solution Husqvarna Fleet

Services

™

gives the fleet manager an overview of all

products that are connected via either embedded or

aftermarket sensors. The position of the gateway or

smartphone can be used to indicate the location of

connected products. The sensors record data like

runtime, service intervals and more. For more

information about the cloud asset management solution

Husqvarna Fleet Services

™

, download the iOS or

Android app Husqvarna Fleet Services at https://

apps.apple.com/se/app/husqvarna-fleet-services/

id1334672726 or https://play.google.com/store/apps/

details?id=com.husqvarna.hfsmobile&hl=en.

Some types of this product are connected via the

embedded Husqvarna Fleet Services

™

sensor that has

the Bluetooth Low Energy (BLE) function. For more

information regarding how to use it, refer to

To use

embedded connectivity on page 12

. For information

about the BLE technology radio spectrum, refer to

Embedded connectivity on page 18

. For compliance

reservations regarding Husqvarna Fleet Services

™

,

refer to

Compliance reservations on page 7

.

6

1188 - 008 - 14.09.2020

Содержание 970445607

Страница 1: ...DM400 DM430 EN Operator s manual 6 20 ES MX Manual del usuario 21 38 FR CA Manuel d utilisation 39 57 ...

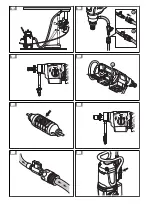

Страница 2: ...1 9 10 7 3 8 11 15 4 12 13 5 14 6 2 1 2 3 4 5 6 7 8 ...

Страница 3: ...9 10 11 A B 12 13 14 15 16 C D ...

Страница 4: ...17 18 A B 19 20 A 21 22 23 24 ...

Страница 5: ...25 26 27 ...