• Maintain power tools and accessories. Check for

misalignment or binding of moving parts, breakage

of parts and any other condition that may affect the

power tool’s operation. If damaged, have the power

tool repaired before use. Many accidents are caused

by poorly maintained power tools.

• Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

• Have your power tool serviced by a qualified repair

person using only identical replacement parts. This

will ensure that the safety of the power tool is

maintained.

Assembly

Introduction

WARNING: Read and understand the safety

chapter before you assemble the product.

WARNING: To prevent injury, disconnect the

power cord and remove the drill bit before

assembly.

To attach the product to a drill stand

CAUTION: Read the operator's manual for

the drill stand carefully.

• To attach the product to a drill stand, refer to the

manual for the drill stand.

• Use only with approved Husqvarna drill stands.

Refer to

Accessories on page 19

.

Operation

To do before you operate the product

1. Read the operator's manual carefully and make sure

that you understand the instructions.

2. Read the operator's manual for the drill stand

carefully and make sure that you understand the

instructions.

3. Use personal protective equipment. Refer to

Personal protective equipment on page 10

.

4. Make sure that the nominal voltage in the mains

socket is the same as the voltage of the product.

5. Make sure that the work area is clean and bright.

6. Make sure that the product is installed correctly. The

drill bit and the drill stand must be attached correctly.

(Fig. 10)

7. When you do inverted drilling, make sure that you

comply to the applicable instructions. Refer to

To

prepare the product for inverted drilling on page 12

.

8. Make sure that the water system is not damaged

and that it is connected to the product.

9. Do the daily maintenance. Refer to

Maintenance

schedule on page 14

.

10. Make sure that the PRCD is started. Refer to

PRCD

on page 11

and

To examine the PRCD on page 11

.

To use embedded connectivity

Note: This part is applicable only for products supplied

with embedded connectivity.

Note: Radio transmission by the Bluetooth

®

function will

be enabled on the first time of connection to a power

outlet, and stay on after that.

1. Download the Husqvarna Fleet Services iOS or

Android app Husqvarna Fleet Services.

2. Go to Husqvarna Fleet Services website https://

fleetservices.husqvarna.com for more information.

To prepare the product for inverted

drilling

WARNING: Always use a slurry ring with a

sealing disc and a rubber washer during

inverted drilling. Water that enters the

product increases the risk of electrical

shock.

1. Clean the top of the slurry ring. All grease and dirt

must be removed.

2. Attach 2-sided adhesive tape or use spray glue

around the top opening of the slurry ring (A). Put the

sealing disc on the top opening as a cover (B).

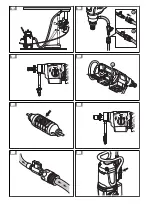

Attach it tightly. (Fig. 11)

3. Look for the dimension of the core drill on the top of

the drill. (Fig. 12)

4. Cut a hole in the sealing disc in the nearest smaller

dimension as the core drill. (Fig. 13)

5. Attach the rubber washer to the quick-release

washer on the drill spindle. (Fig. 14)

6. Connect the slurry collector to the connection of the

slurry ring. (Fig. 15)

12

1188 - 008 - 14.09.2020

Содержание 970445607

Страница 1: ...DM400 DM430 EN Operator s manual 6 20 ES MX Manual del usuario 21 38 FR CA Manuel d utilisation 39 57 ...

Страница 2: ...1 9 10 7 3 8 11 15 4 12 13 5 14 6 2 1 2 3 4 5 6 7 8 ...

Страница 3: ...9 10 11 A B 12 13 14 15 16 C D ...

Страница 4: ...17 18 A B 19 20 A 21 22 23 24 ...

Страница 5: ...25 26 27 ...