14

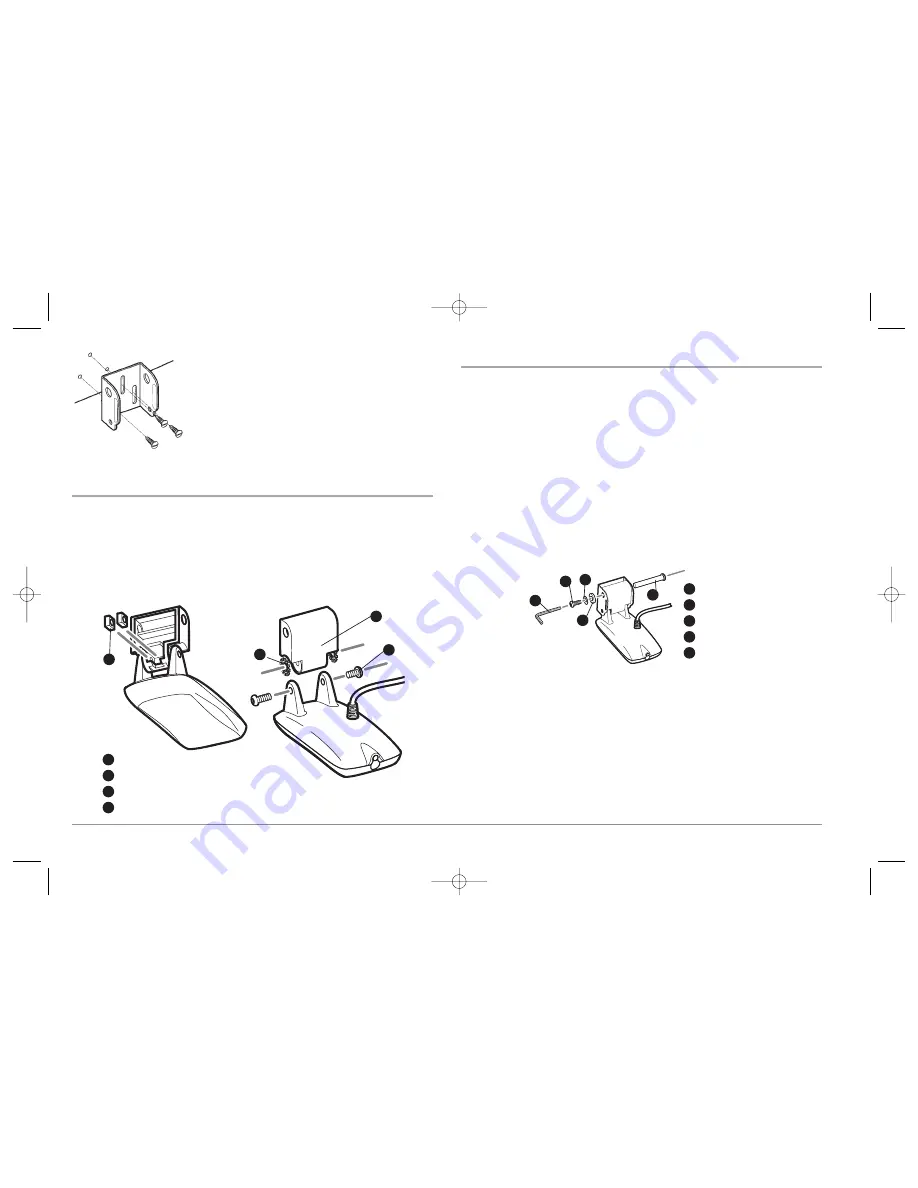

5. Align the metal mounting bracket with the mounting

holes. The center slot should be above the two outer

slots. (This bracket and all other hardware supplied is top

quality stainless steel for maximum strength and

corrosion protection.) Insert the three 1" (25 mm) flat

head wood screws into the drilled holes, but do not

completely tighten.

To attach the pivot to the transducer:

1. Attach the pivot to the transducer body, using the two 1/4"-20 x 5/8" (16 mm)

machine screws, toothed washers, and square nuts. The toothed washers must

fit on the inside of the transducer ears, between the pivot and the ears. The

square nuts will be prevented from rotating by the pocket in the back of the

pivot. An Allen wrench is provided which fits all the 1/4"-20 screws, but do not

fully tighten the screws at this time.

To mount the transducer pivot assembly to the bracket:

1. Slide the assembled transducer into the metal bracket from the bottom,

aligning the large hole at the top of the bracket with the hole in the pivot.

2. Insert the headed pin through the pivot holes in the bracket and pivot. The

headed pin can be inserted from either side of the bracket.

3. Place the nylon washer over the opposite end of the headed pin. Place the

stainless washer over the 1/4"-20 x 5/8" (16 mm) screw threads, then insert into

the opposite end of the headed pin and finger tighten only. The screw has a

thread locking compound on the threads to prevent loosening, and should not

be fully tightened until all adjustments are made.

NOTE:

The running position of the transducer is now completely adjustable. Subsequent

adjustment may be necessary to tweak the installation after high speed testing.

Screw

1

Headed Pin

2

Allen Wrench

3

Nylon Washer

4

Stainless Washer

5

3

1

5

4

2

Attach the Pivot

2

3

4

1

Insert the square nuts

1

Toothed Washer

2

Pivot

3

Machine Screw

4

Attaching the Bracket

98x_Manual_531376-1_A.qxd 2/23/2005 11:39 AM Page 20

![Предварительный просмотр 6 страницы Humminbird ] 981 Installation & Operation Manual](http://thumbs.mh-extra.com/thumbs/humminbird/981/981_installation-and-operation-manual_2183846-06.webp)

![Предварительный просмотр 7 страницы Humminbird ] 981 Installation & Operation Manual](http://thumbs.mh-extra.com/thumbs/humminbird/981/981_installation-and-operation-manual_2183846-07.webp)

![Предварительный просмотр 8 страницы Humminbird ] 981 Installation & Operation Manual](http://thumbs.mh-extra.com/thumbs/humminbird/981/981_installation-and-operation-manual_2183846-08.webp)

![Предварительный просмотр 9 страницы Humminbird ] 981 Installation & Operation Manual](http://thumbs.mh-extra.com/thumbs/humminbird/981/981_installation-and-operation-manual_2183846-09.webp)

![Предварительный просмотр 10 страницы Humminbird ] 981 Installation & Operation Manual](http://thumbs.mh-extra.com/thumbs/humminbird/981/981_installation-and-operation-manual_2183846-10.webp)

![Предварительный просмотр 11 страницы Humminbird ] 981 Installation & Operation Manual](http://thumbs.mh-extra.com/thumbs/humminbird/981/981_installation-and-operation-manual_2183846-11.webp)

![Предварительный просмотр 12 страницы Humminbird ] 981 Installation & Operation Manual](http://thumbs.mh-extra.com/thumbs/humminbird/981/981_installation-and-operation-manual_2183846-12.webp)

![Предварительный просмотр 13 страницы Humminbird ] 981 Installation & Operation Manual](http://thumbs.mh-extra.com/thumbs/humminbird/981/981_installation-and-operation-manual_2183846-13.webp)

![Предварительный просмотр 14 страницы Humminbird ] 981 Installation & Operation Manual](http://thumbs.mh-extra.com/thumbs/humminbird/981/981_installation-and-operation-manual_2183846-14.webp)

![Предварительный просмотр 15 страницы Humminbird ] 981 Installation & Operation Manual](http://thumbs.mh-extra.com/thumbs/humminbird/981/981_installation-and-operation-manual_2183846-15.webp)

![Предварительный просмотр 16 страницы Humminbird ] 981 Installation & Operation Manual](http://thumbs.mh-extra.com/thumbs/humminbird/981/981_installation-and-operation-manual_2183846-16.webp)

![Предварительный просмотр 17 страницы Humminbird ] 981 Installation & Operation Manual](http://thumbs.mh-extra.com/thumbs/humminbird/981/981_installation-and-operation-manual_2183846-17.webp)

![Предварительный просмотр 18 страницы Humminbird ] 981 Installation & Operation Manual](http://thumbs.mh-extra.com/thumbs/humminbird/981/981_installation-and-operation-manual_2183846-18.webp)

![Предварительный просмотр 19 страницы Humminbird ] 981 Installation & Operation Manual](http://thumbs.mh-extra.com/thumbs/humminbird/981/981_installation-and-operation-manual_2183846-19.webp)

![Предварительный просмотр 20 страницы Humminbird ] 981 Installation & Operation Manual](http://thumbs.mh-extra.com/thumbs/humminbird/981/981_installation-and-operation-manual_2183846-20.webp)

![Предварительный просмотр 21 страницы Humminbird ] 981 Installation & Operation Manual](http://thumbs.mh-extra.com/thumbs/humminbird/981/981_installation-and-operation-manual_2183846-21.webp)

![Предварительный просмотр 22 страницы Humminbird ] 981 Installation & Operation Manual](http://thumbs.mh-extra.com/thumbs/humminbird/981/981_installation-and-operation-manual_2183846-22.webp)

![Предварительный просмотр 23 страницы Humminbird ] 981 Installation & Operation Manual](http://thumbs.mh-extra.com/thumbs/humminbird/981/981_installation-and-operation-manual_2183846-23.webp)

![Предварительный просмотр 24 страницы Humminbird ] 981 Installation & Operation Manual](http://thumbs.mh-extra.com/thumbs/humminbird/981/981_installation-and-operation-manual_2183846-24.webp)

![Предварительный просмотр 25 страницы Humminbird ] 981 Installation & Operation Manual](http://thumbs.mh-extra.com/thumbs/humminbird/981/981_installation-and-operation-manual_2183846-25.webp)

![Предварительный просмотр 26 страницы Humminbird ] 981 Installation & Operation Manual](http://thumbs.mh-extra.com/thumbs/humminbird/981/981_installation-and-operation-manual_2183846-26.webp)

![Предварительный просмотр 27 страницы Humminbird ] 981 Installation & Operation Manual](http://thumbs.mh-extra.com/thumbs/humminbird/981/981_installation-and-operation-manual_2183846-27.webp)

![Предварительный просмотр 28 страницы Humminbird ] 981 Installation & Operation Manual](http://thumbs.mh-extra.com/thumbs/humminbird/981/981_installation-and-operation-manual_2183846-28.webp)

![Предварительный просмотр 29 страницы Humminbird ] 981 Installation & Operation Manual](http://thumbs.mh-extra.com/thumbs/humminbird/981/981_installation-and-operation-manual_2183846-29.webp)

![Предварительный просмотр 30 страницы Humminbird ] 981 Installation & Operation Manual](http://thumbs.mh-extra.com/thumbs/humminbird/981/981_installation-and-operation-manual_2183846-30.webp)

![Предварительный просмотр 31 страницы Humminbird ] 981 Installation & Operation Manual](http://thumbs.mh-extra.com/thumbs/humminbird/981/981_installation-and-operation-manual_2183846-31.webp)

![Предварительный просмотр 32 страницы Humminbird ] 981 Installation & Operation Manual](http://thumbs.mh-extra.com/thumbs/humminbird/981/981_installation-and-operation-manual_2183846-32.webp)

![Предварительный просмотр 33 страницы Humminbird ] 981 Installation & Operation Manual](http://thumbs.mh-extra.com/thumbs/humminbird/981/981_installation-and-operation-manual_2183846-33.webp)

![Предварительный просмотр 34 страницы Humminbird ] 981 Installation & Operation Manual](http://thumbs.mh-extra.com/thumbs/humminbird/981/981_installation-and-operation-manual_2183846-34.webp)

![Предварительный просмотр 35 страницы Humminbird ] 981 Installation & Operation Manual](http://thumbs.mh-extra.com/thumbs/humminbird/981/981_installation-and-operation-manual_2183846-35.webp)