21

a fully manual adjustable double pulse. These options

are available regardless of the material (mild steel,

stainless steel, silicon bronze, or aluminum) and wire

diameter. These pulse features work regardless of which

MIG gun you use; air-cooled, water-cooled, spool gun,

or push-pull gun all work equally well with these pulse

features.

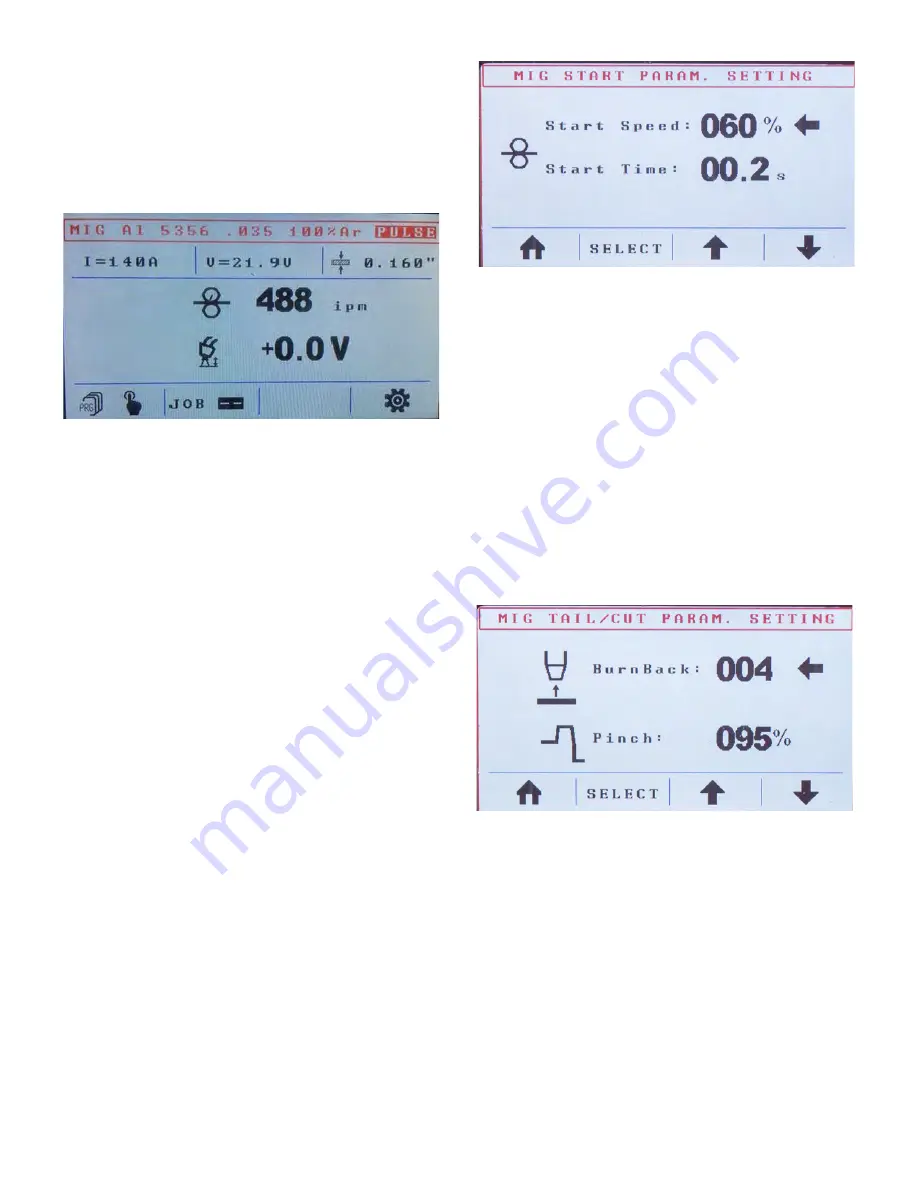

Fig. 23

Once you select a program, the program list disappears,

and the program is displayed (

Fig. 23

). The top line in

the display shows the name of the program, the wire

diameter, and the required gas/gas mixture. It also

indicates if it is a synergic or a pulse program. The line

below displays, starting from the left, the approximate

amperage (calculated based on the material, wire speed,

wire diameter, and other variables), arc voltage, and

material thickness. By turning left encoder

F

(

Fig. 4

),

you can adjust the material thickness; adjusting the

material thickness also adjusts, automatically, the wire

speed and the voltage.

In the center of the LCD, the wire speed is displayed in

IPM. Below that, the voltage deviation of the synergic

curve is displayed. This value is supposed to read 0.0 V

at most times, for most welding operations. You can

adjust this value by turning right encoder

G

(

Fig. 4

). If

an adjustment is made, the absolute arc voltage changes,

and the color in the display changes from black to red. A

deviation of the synergic arc does two things: it changes

the arc length and it makes the weld hotter or colder.

However, on a synergic machine, the main heat

adjustment is made with left encoder

F

(

Fig. 4

) by

setting the material thickness. The voltage deviation

made with encoder

G

is considered fine-tuning or a

personal preference adjustment.

You will find the function buttons (

Fig. 4; B, C, D, & E

)

on the bottom of the display. In this case (

Fig. 23

),

button

B

, if pressed and released once, brings up the

program list, or, if quickly pressed and released twice,

switches the machine into manual mode. Pressing button

C

accesses the Job menu, button

D

has no function at

this point, and pressing button

E

accesses the advanced

setup menu.

Fig. 24

By pressing and releasing button

E

(

Fig. 4

)

once, you

enter the setup menu (

Fig. 24

). The first screen in the

setup menu gives you the option to adjust the run-in

speed (Start Speed). Typically, numbers between 35%

and 70% are suitable for the run-in speed. Start Time

determines how long the machine runs at the slower run-

in speed once the arc is struck and before it switches to

100% wire speed. Start times between 0.1 and 0.3

seconds are common. Correct adjustment of the start

parameter allows for a spatter-free and smooth arc

initiation. To set the start speed, turn right encoder

G

(

Fig. 4

); to set the start time, press and release button

C

(

Fig. 4; the little arrow will move down from Start

Speed to Start Time

). Turning right encoder

G

now

adjusts the start time.

Fig. 25

To go to the next screen, press and release button

E

(

Fig.

4

). The new screen (

Fig. 25

) allows you to adjust what

the wire does upon weld completion. Burn back adjusts

how long the wire sticks out after you finish welding. A

low number allows the wire to stick out as it normally

does on a classic MIG welder, without any adjustments.

The higher the number, the shorter the stick-out

(

Attention:

High bur n back number s cr eate the risk

of burning the wire back into the contact tip. We

recommend starting out with very low numbers).

Different wires react differently. For example, aluminum

reacts differently than steel; when welding aluminum,

set burn back to 004. The pinch function clips wire

electrically. Right before you finish the weld, the

machine sends a burst of current that shapes the end of

Содержание Pro Pulse 300

Страница 6: ...6 Fig 1...

Страница 8: ...8...

Страница 31: ...31 Pro Pulse 300 Wiring Diagram...

Страница 32: ...32 Pro Pulse 300 Parts Diagram...