Chapter 3

3-5

Gauging and Making Connections

Preventive Maintenance

Preventive Maintenance

The best techniques for maintaining the integrity of the devices in this

kit include:

• routine visual inspection

• cleaning

• proper gauging

• proper connection techniques

Failure to detect and remove dirt or metallic particles on a connector

mating plane surface can degrade repeatability and accuracy, and can

damage any connector mated to it.

Improper connections, resulting from pin depth values being out of the

“Observed Pin Depth Limits” (see

through

), or from

using poor connection techniques, can also damage these devices.

Visual inspection, cleaning and proper connection techniques, along

with proper gauging for pin depth, are all described in this chapter.

Содержание HP 85060B

Страница 5: ...1 1 1 General Information ...

Страница 17: ...Chapter 1 1 13 General Information Safety and Regulatory Information ...

Страница 18: ...2 1 2 Specifications and Characteristics ...

Страница 36: ...3 1 3 Gauging and Making Connections ...

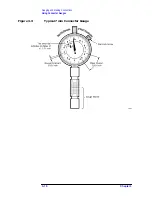

Страница 50: ...Chapter 3 3 15 Gauging and Making Connections Using Connector Gauges Figure 3 2 Typical 3 5 mm Connector Gauge ...

Страница 51: ...3 16 Chapter3 Gauging and Making Connections Using Connector Gauges Figure 3 3 Typical 7 mm Connector Gauge ...

Страница 52: ...Chapter 3 3 17 Gauging and Making Connections Using Connector Gauges Figure 3 4 Typical Type N Connector Gauge ...

Страница 61: ...3 26 Chapter3 Gauging and Making Connections Gauging Techniques Figure 3 8 Using a 3 5 mm Connector Gauge ...

Страница 65: ...3 30 Chapter3 Gauging and Making Connections Making Type F Connections Figure 3 9 Type F Female Connectors ...

Страница 67: ...4 1 4 Replaceable Parts ...