Page 22

Installer’s Information Manual

Example

:

Assume it took 29 seconds for one cubic foot of gas to flow

and heating value of 1,000 Btu/cu.ft.

1,000 x 3,600

Gas Input =

= 124,138 Btu per hour

29

If you left no other pilots on, this is the furnace gas input.

8. If you left water heater, dryer or range pilots on, allow

for them in calculating correct fu rnace gas input. A

quick way is to allow 1,000 Btu per hour for a water

heater, 500 Btu per hour for dryer and 500 Btu per hour

for each range b urner pilot.

Example:

If you left gas water heater, dryer, two range burner pilots

and one oven pilot on, allow:

Water heater pilot

1,000 Btu per hour

Dryer pilot

500 Btu per hour

2 range burner pilots

1,000 Btu per hour

1 range oven pilot

500 Btu per hour

3,000 Btu per hour

Subtracting 3,000 Btu per hour from 124,138 Btu per hour

measured above equals 121,138 Btu per hour. This would

be the correct furnace gas input after allowing for pilots left

on.

9. Manifold pressure may be adjusted within the range of

3.2 inches W.C. to 3.8 inches W.C. to get rated input ±

2 percent. See Section 13, "Manifold Pressure

Adjustment." If you cannot get rated input with

manifold pressure within the allowable range, you must

change orifices. See Section 17, "Changing Main

Burner Orifices."

PROPANE (LP) GAS INPUT RATE

WARNING

: Propane (LP) gas installations do not

have gas meters to double-check input rate. Measure

manifold pressure with an accurate manometer. Failure to

accurately adjust pressure could cause heat exchanger

failure.

1. Make sure you have correct pilot orifice and main

burner orifices.

2. Gas supply pressure must be between 11 and 13

inches W.C. for propane (LP) gas. See Section 12,

"Gas Supply Pressure and Pilot Adjustment."

3. Start furnace following "Operating Instructions" on front

door.

4. Let furnace warm up for 6 minutes.

5. Adjust manifold pressure to 10.0 inches W.C. ± 0.3

inches W.C. See Section 13, "Manifold Pressure

Adjustment."

WARNING

: Do not set Propane (LP) manifold

pressure at 11.0 inches W.C. It could cause heat

exchanger failure.

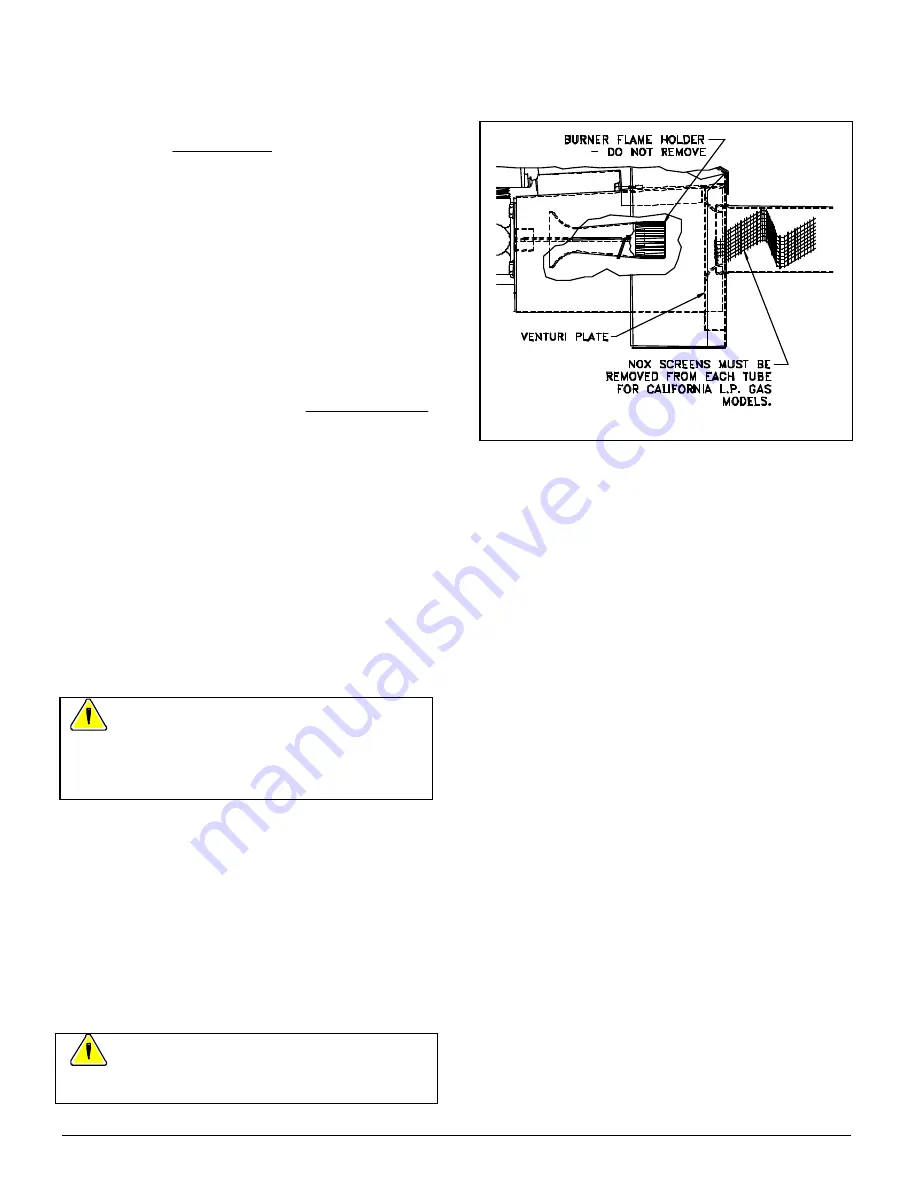

NOTE: NOx reducing screens must be removed from each

tube of California NOx furnaces when converting to

propane (LP) gas. See Figure 20.

Figure 20. California NOx Screen Removal.

SECTION 15. DERATING FOR HIGH

ALTITUDE

At higher altitudes, the density of the air is lower.

Therefore, for proper combustion, the quantity of gas

burned in the furnace must be reduced. This is called

derating. Furnaces must be derated when installed at

altitudes greater than 2,000 feet above sea level.

Derating the furnace by adjusting the manifold pressure

lower than the range specified in the Section 13, "Manifold

Pressure Adjustment" is considered to be an improper

procedure.

At elevations above 2,000 feet, the furnace must be

derated 4% for each 1,000 foot above sea level. It is the

installer’s responsibility to see that the fu rnace input rate is

adjusted properly. Derating must be achieved by reducing

the size of the main burner orifices. Choose the proper

orifices for your altitude and gas heating value from orifice

size Table 7 or 8. In Canada, high-altitude models may be

available that are rated for 2,000 to 4,500 feet above sea

level.

SECTION 16. DETERMINING

CORRECT ORIFICE SIZE

See Table 7 or Table 8 to determine correct orifice size for

your gas type, gas heating value, and altitude. Natural gas

and propane (LP) gas orifice kits are available through your

supplier. Individual orifices are also available in convenient

lot sizes. To ensure proper performance, use only

manufacturer supplied orifices. To determine which orifices

are installed in fu rnace, see rating plate --located on blower

door.