9

Leg

end:

Comp

- compressor

FMS

- self-contained f

an motor

FWV

- freez

e w

ater v

alv

e

HGV

- hot gas v

alv

e

HWV

- har

vest w

ater v

alv

e

LF/S

- lo

w

er float s

witch

PM

- pump motor

UF/S

- upper float s

witch

Components Ener

giz

ed when the Contr

ol Switc

h is in the

W

ASH P

osition

The

W

ASH position on the control s

witch is used when cleaning and sanitizing the machine

. When in

the

W

ASH position, po

w

er is supplied to the pump motor and the w

ash v

alv

e.

This allo

ws cleaner and

sanitiz

er to flo

w o

ver both the inside and outside of the e

vapor

ator plate assemb

ly

.

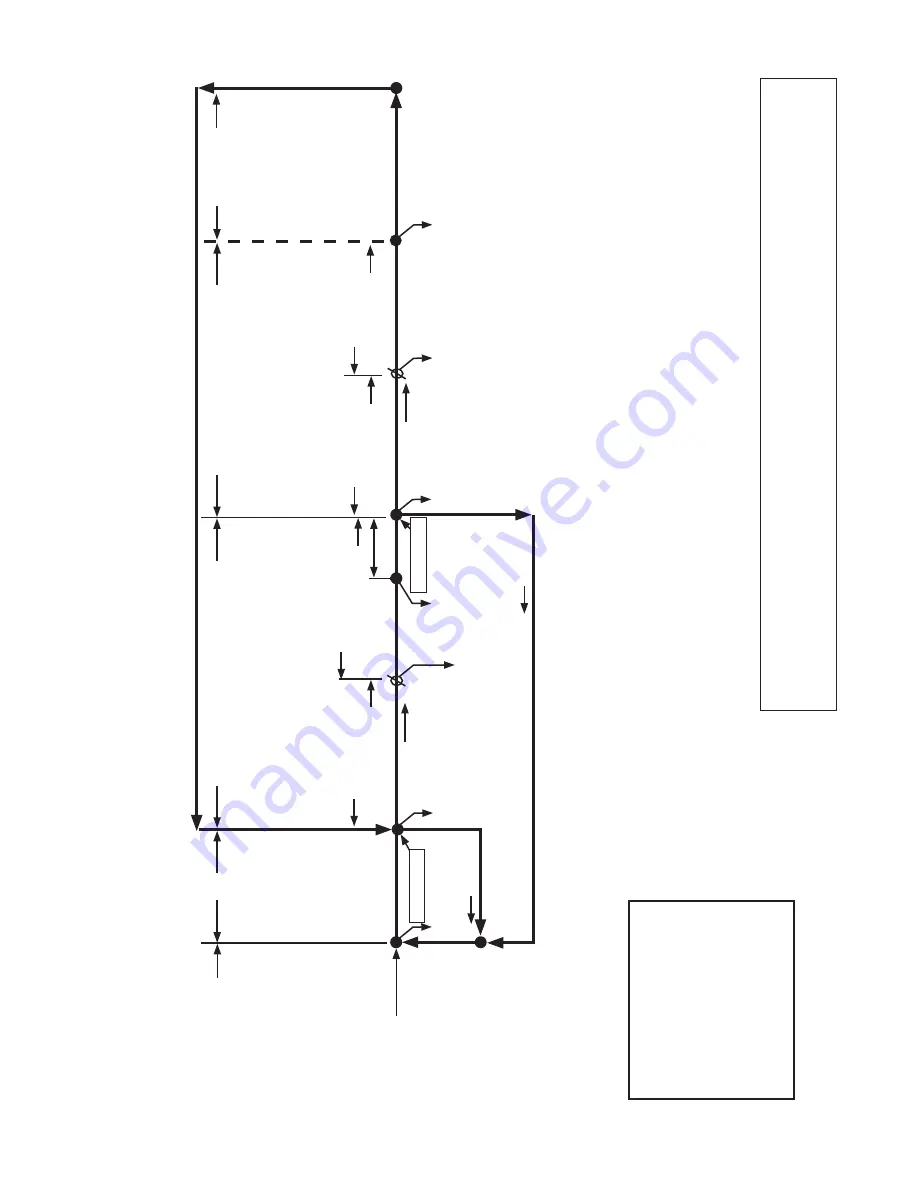

KM-251B

AH Sequence Flo

w Char

t and Component Operation

1.

One Min

ute

Fill Cyc

le

2.

Har

vest Cyc

le

3.

Freez

e Cyc

le

Pump motor stops

for 2 sec.

and then

runs f

or 10 sec.

Cyc

le Steps

FWV

Energiz

ed

LF/S

open

LF/S

closed

Comp

energiz

ed

HGV

energiz

ed

FWV

de-energiz

ed

HWV

energiz

ed

Ther

mistor temp

reaches 48

°F (9°C)

(3.9 k

Ω

or less)

Har

vest timer star

ts

LF/S

open

Comp

contin

ues

HGV

de-energiz

ed

HWV

de-energiz

ed

PM

contin

ues

FMS

energiz

ed

FWV

energiz

ed/

de-energiz

ed

f

or refills only

LF/S

closed

Freez

e cycle

oper

ation tur

ned

ov

er to

LF/S

Comp

contin

ues

HGV

energiz

ed

FMS

de-energiz

ed

LF/S

Chec

k

LF/S

Chec

k

• Maxim

um har

vest w

ater v

alv

e time:

6 min

utes

(HWV time is 6 min

utes or the length of

har

vest min

us 50 sec., whiche

ver is shor

ter

.

PM energiz

es and r

uns f

or the last 50 sec.

of

har

vest.)

• Maxim

um har

vest time:

20 min

utes

Ther

mistor in

control

1 to 3 min

ute timer

in control

• Minim

um freez

e time:

5 min

utes

•

Maxim

um

freez

e

time:

freez

e

timer

setting

• Upper float s

witch used to initiate and

complete w

ater tank refills (9 refills f

or

KM-251BAH)

5 min

ute timer

in control

Lo

w

er float

switch in

control

Initial star

tup alw

ays

begins here

"G" board will ha

ve

5 second dela

y

If

LF/S

is open, compressor stops and cycle retur

ns to 1 min

ute fill

End of 1st

freez

e and

ev

er

y 10th

cycle thereafter

50 sec.

PM

energiz

ed