P7810A-D PRESSURETROL® CONTROLLER

9

65-0268—1

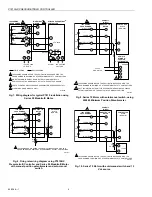

Table 5. Reset Switch Function, P7810C,D.

Table 6. Setting Maximum Fixed Stop Limit Value—

Current Readings.

Changing the Maximum Fixed Stop Limit

Value Setting (if Run Time is less than one

hour)

1.

Remove power from the P7810C,D.

2.

Press and hold the Reset Switch, then apply power to

the P7810C,D.

3.

When the green LED blinks rapidly, release the Reset

Switch.

4.

Follow the steps in Setting the Maximum Fixed Stop

Limit Value, above.

NOTE: If both LEDs turn on, the configuration timer (one

hour) has expired. Release the Reset button and

continue normal operation. Changing the Maximum

Fixed Stop Limit Value Setting is no longer allowed.

Checking the Maximum Fixed Stop Limit

Value (Stored in Memory)

NOTE: The P7810C,D must be powered and in the Run

mode.

Reset Switch

Action

P7810C,D Modes of Operation

Lockout

Unconfigured

(Run) Normal

Operation

Power-up

(Configuration

Time Expired)

Power-up

(Configuration

Time Not Expired)

Press and

Continuously Hold.

Blink existing fault

code until the reset

switch is released.

Both LEDs turn on

after three seconds,

indicating the

Maximum Fixed

Stop Limit Value has

been stored. Wait

for up to 30 seconds

for a release. Enter

lockout after 30

seconds.

The green LED

turns off and the

yellow LED turns

on, waiting until the

reset switch is

released.

Both LEDs turn on.

Wait for up to 30

seconds for a

release. Lockout

after 30 seconds. If

released within 30

seconds, enter

normal operation.

Enter unconfigured

mode of operation.

Press and release. Clear the fault code

and reset the

P7810.

Press and release

of the Reset button

within three

seconds is ignored.

If the Reset button

is pressed for more

than three seconds,

both LEDs turn on

and the Maximum

Fixed Stop Limit

Value is stored into

non-volatile (NV)

memory. Upon

release, the device

will recycle and

enter normal

operation.

Resets the control.

Enter normal

operation.

Enter unconfigured

mode of operation.

15 psi

150 psi

300 psi

4-20 mA Output

0

0

0

4.00

1

10

20

5.07

2

20

40

6.13

3

30

60

7.20

4

40

80

8.27

5

50

100

9.33

6

60

120

10.40

7

70

140

11.47

8

80

160

12.53

9

90

180

13.60

10

100

200

14.67

11

110

220

15.73

12

120

240

16.80

13

130

260

17.87

14

140

280

18.93

15

150

300

20.00