P7810A-D PRESSURETROL® CONTROLLER

65-0268—1

4

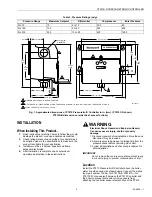

Controller next to the pressure gauge in the

manufacturer-provided fitting on the boiler. See Fig. 2 and 4.

Mount at a remote location to avoid excessive vibration, or

mount in a special mounting on a low water cutoff.

IMPORTANT

1. Locate the P7810 Pressuretrol® Controller where

ambient temperature does not exceed 140°F (60°C).

2. Use pipe compound sparingly to avoid clogging the

hole in the pipe or the sensor element fitting.

3. Do not hand tighten the controller connection by

holding the case. Use a wrench on the flats of the

sensor fitting to avoid leaks and damage to the case.

4. Level the controller for appearance.

5. Install the P7810 where the relative humidity never

reaches the saturation point. The P7810 is designed

to operate in a maximum 85 percent relative

humidity, continuous, noncondensing moisture

environment. Condensing moisture can cause a

shutdown.

6. Do not install the P7810 where it could be subjected

to vibration in excess of 0.5G continuous maximum

vibration.

7. The P7810 is not designed to be weather tight. If

installed outdoors, protect the P7810 with an

approved weather-tight enclosure.

CAUTION

Equipment Damage Hazard.

Incorrect installation of the L404 Pressure

Controller can damage the equipment and may

require boiler replacement.

Install the L404C Pressuretrol® as shown in Fig. 2 and

3 to prevent equipment damage.

Fig. 2. Connecting P7810A,B Pressuretrol® Controller to

steam boiler.

Fig. 3. Right and wrong mounting of steam trap (siphon

loop) for the L404 Pressuretrol® Controller, with

approximate dimensions in in. (mm).

Mounting

Make all pipe connections in accordance with applicable local

standards. Use parallel jaw wrench to tighten P7810

Controller hexagonal fitting to avoid leaks and damage to the

case.

Mounting P7810 Controller Next to Pressure Gauge

To mount the P7810 Pressuretrol® Controller next to the

pressure gauge:

1.

Remove the pressure gauge.

2.

Replace the gauge with a siphon loop with tee

connector on top.

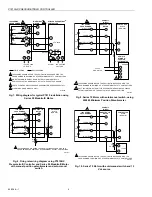

Fig. 4. Connecting P7810C,D Pressuretrol® Controller to

steam boiler.

P7810A,B

L404C

LIMIT

L91

GAUGE

MOD.

BOILER

M4879B

SIPHON

LOOP

4-1/2 TO 5-1/2

(114.3 TO 139.7)

BOILER

14026

STEAM TRAP

(SIPHON LOOP)

TEE

PRESSURE

GAUGE

PRESSURE

CONTROLLER

M8934A

1

1

1/4 IN. BLACK IRON PIPE WITH 1/4 - 18 NPT EXTERNAL

TRHEADS ON BOTH ENDS. BEND THE STEAM TRAP

(SIPHON LOOP) TO LEVEL THE CONTROLLER.

CORRECT

BOILER

2-1/4

(57.2)

DIA.

INCORRECT

P7810C,D

GAUGE

BOILER

M11891