P7810A-D PRESSURETROL® CONTROLLER

11

65-0268—1

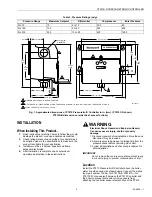

Table 8. LED Fault Codes and Recommended Troubleshooting.

CHECKOUT

WARNING

Electrical Shock Hazard and Explosion Hazard.

Can cause severe injury, death or property

damage.

1. Live voltage is present at the P7810 and all

controller circuits. Use extreme care during

checkout.

2. This checkout procedure disables the Safety High

Limit function.

IMPORTANT

1. Do not put the system into service until all applicable

tests described in the Checkout section of the

instructions for the primary safety control and any

additional tests required by the burner or boiler

manufacturer are satisfactorily completed.

2. Close all manual fuel shutoff valves when trouble

occurs.

After installation and wiring, check out the P7810

Pressuretrol® Controller with the system in operation.

Checkout

1.

Allow the system to stabilize.

2.

Observe the operation of the P7810 while raising and

lowering the setpoint. Pressure increases when the

setpoint is increased and decreases when the setpoint

is decreased.

3.

Check the make and break points of the P7810. If they

do not agree with a separate, accurately calibrated

pressure gauge, make a slight adjustment according to

the scale. Use accurate pressure testing equipment

when checking out the P7810. Do not rely on

inexpensive gauges. The P7810 is carefully calibrated

at the factory.

Test the P7810 Pressuretrol® Controller as follows:

NOTE: Make sure the P7810 is operating properly by

checking the LED indicators. If the P7810 LEDs

indicate a lockout condition, press the manual reset

button.

NOTE: This procedure simulates pressure changes using

knob setpoint adjustments. Make knob adjustments

very slowly because of filtering delays within the

P7810 (20 to 25 seconds for full scale change).

Inaccuracy can result if knob adjustments are not

made very slowly. To observe actual P7810 control

accuracy, set the knobs to normal operating values.

Compare the knob settings to the boiler pressure

readings where P7810 actions occur.

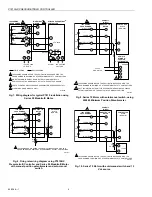

To check the control setpoint of the P7810A,B,C,D:

1.

Note the boiler pressure by checking the boiler pressure

gauge. To properly perform these tests, the boiler

pressure should be near the middle of the P7810

pressure range.

2.

Turn the P7810 limit setpoint knob fully clockwise to

make sure this limit does not interfere during steps

4

and

5

. This setting must return to the proper operating

position when returning the system to normal operation.

3.

Check the control setpoint and control differential.

4.

Set the control differential knob to the center of its

range.

5.

Turn the control setpoint knob fully counterclockwise

and make sure the P7810 control circuit is open and the

green LED is off (no call for heat).

6.

Read the boiler pressure gauge and add this number to

the control differential setting.

7.

Turn the control setpoint knob slowly clockwise and

make sure the control circuit closes and the P7810 indi-

cates a call for heat (green LED on) when the P7810

control setpoint passes through the value determined in

step

6

.

8.

Turn the control setpoint knob slowly counterclockwise

and make sure the control circuit opens and the P7810

no longer indicates a call for heat (green LED off) when

the control setpoint passes through the boiler pressure

gauge value.

Check the modulation setpoint and modulation range of the

P7810B,C as follows:

1.

Set the P7810 modulation range knob to the center of

the range.

2.

Turn the modulation setpoint knob fully clockwise and

make sure the firing rate motor travels to the fully open

position (boiler is firing).

3.

Turn the modulation setpoint knob slowly

counterclockwise and make sure the firing rate motor

starts moving toward the closed position when the

modulation setpoint passes through the boiler pressure

gauge value. (Alternately, make sure the current starts

decreasing toward 4 mA.)

Fault Code

System Failure

Recommended Troubleshooting

11

High Limit Setpoint Exceeded.

When pressure in vessel returns to normal, P7810 can be reset.

12-32,

71-90, 92

Internal fault

Reset P7810; if same fault occurs again, replace P7810.

51, 54, 61

Internal fault—internal relays

welded

Verify loads do not exceed rating of P7810 contacts, then replace P7810.

52-69, 91

Relay fault

Verify that no voltage potential exists on Output terminal.

If code repeats after normal operation, look for back feed of voltage greater

than 50V (ac or dc) any time during boiler sequence.

Replacing P7810 will only result in same lockout on new control.