l

Do NOT connect together and attempt to test multiple lengths of ControlNet trunk cable.

Doing so will invalidate the test and will not ensure accurate results.

l

Both ends of every ControlNet trunk cable section must be tested.

l

Keep the TDR batteries (if used) fully charged.

l

The cables connectors must be installed using the correct tools. If it appears the

connection was made with pliers, channel-locks, or vice-grips,

reject the cable.

l

Look for folds or kinks in the cable sheathing, indicating that the minimum bend-radius

was exceeded;

reject the cable.

l

Do not compromise on the accuracy of the test terminator. This test procedure depends

on the delta difference between the terminator and the cable section under test.

6.3.1

To test each length of cable

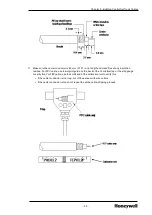

1. With no cable connected, verify that your TDR screen appears as shown.

Settings are:

l

X10 & .5ft/Div

l

0 dB & 0 dB Loss

2. Connect one end of your cable to the cable jack on the TDR; do NOT terminate the loose end. You

screen should appear as shown in one of the following figures.

If your settings are:

l

2 m (6.5 ft) example

l

X10 & .5ft/Div

l

0 dB & 0 dB Loss

l

No Terminator

- 44 -

Chapter 6 - Testing ControlNet Trunk Cables