47

C08UE001-1912

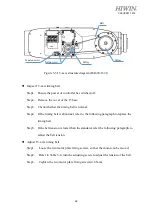

J5 -axis zero position setting

Step1: Operate J5 at low speed to align the pinhole of J6 base with the pinhole of J5 base.

Step2: Insert the calibration tool for J5 to the pinhole to calibrate zero position.

Step3: Complete the calibration and remove the calibration tool.

Step4: Clear encoder by HRSS.

Step5: Resetting zero position of J5 -axis is completed.

Figure 4-6Illustration of J5-axis zero position setting

J6-axis zero position setting

Step1: Operate J6 at low speed to align the keyway of EE with the keyway of J6 base.

Step2: Insert the calibration tool for J6 to the keyway to calibrate zero position.

(Previous version refer to Figure 4-7(b), align the calibration mark with the keyway.)

Step3: Complete the calibration and remove the calibration tool.

Step4: Clear encoder by HRSS.

Step5: Resetting zero position of J6-axis is completed.

4-7(a) 4-7(b)

Figure 4-7 Illustration of J6 -axis zero position setting

Mark for calibration

Calibration tool

Содержание RA620-1621

Страница 1: ...www hiwin tw User Manual Articulated Robot RA620 Original Instruction...

Страница 35: ...34 C08UE001 1912 Figure 2 3 Outer dimension and motion range RA620 1621 J1 0 deg...

Страница 37: ...36 C08UE001 1912 Figure 2 5 Wrist load diagram RA620 1621...

Страница 54: ...53 C08UE001 1912 Table 5 3 Inspection schedule...