--- 16 ---

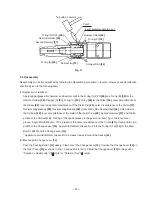

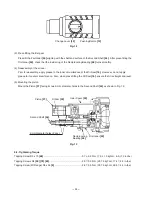

Slip mechanism

The slip mechanism in the Model DH 24PB2 consists of a coil spring which applies a pre-set amount of

pressure to ensure the interlocking of three claws provided on the flange of the cylinder (the final rotating

shaft) and three matching claws provided on the face of the second gear, by which rotation is transmitted to

the cylinder. The second gear is fitted to the cylinder with a certain amount of play.

If an excessively large torque is applied to the tool shaft (cylinder), the force of the torque will exceed the

pressure of the coil spring and cause the claws on the second gear to disengage from and ride over the claws

on the cylinder so that the second gear idles and does not transmit rotation. Even should the drill bit come in

contact with a reinforcing bar within the concrete, causing sudden excessive torque, the slip mechanism

functions to prevent damage to the gears, and possible loss of control of the tool by the operator.

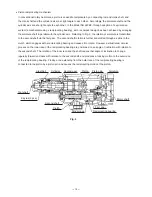

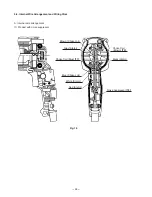

Sealed and dustproof construction

The gear cover is totally enclosed by oil seals, O-rings and other devices to prevent leakage of lubricating

grease, and to keep dust and dirt out of the internal mechanisms. The drill bit chuck portion is protected by a

rubber front cap to keep out dust and chips which could cause improper fitting of the drill bit and/or other faulty

operation of the chuck portion. The speed control switch is also a fully dust-proofed type to prevent dust and

chips from entering the handle section and causing possible operational trouble or a break down of the

insulation.

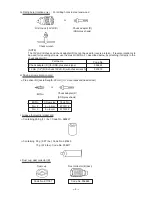

Speed control

The Model DH 24PB2 is equipped with a variable speed control switch which permits free change of the

rotation speed and hamemring force. When drilling in fragile materials, pull the switch trigger gently for low

rotation speed (hammering force) to achieve optimum results. Note that the switch trigger cannot be pulled to

the full but up to the half in the reverse drilling, and the speed is about half of the forward drilling. In addition,

the switch stopper cannot be used in the reverse drilling.

Содержание DH24PB2

Страница 39: ......