--- 13 ---

8. REFERENCE MATERIAL

8-1. Lubrication

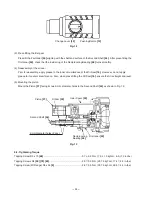

It is not necessary to replenish the grease lubricant unless the tool is disassembled or there is grease leakage

due to a defective seal. Special grease is used in the striking section. Should the striking section (within the gear

cover) be disassembled, carefully remove the old grease from all parts and, on reassembly, insert 50 g (1.8 oz) of

new grease into the gear cover and 10 g (0.4 oz) into the groove of the inner cover. Be careful not exceed the

designed amount of grease. Excessive grease will reduce striking efficiency.

Apply Molub Alloy No. 777-1 grease to the outer circumference of the clutch groove and the pin portion of the

change lever.

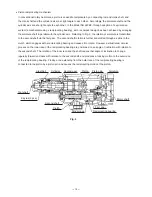

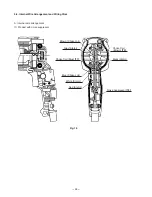

8-2. Tool Structure

While the structure is essentially the same as the Model DH 24PB, the descriptions below are included to

enhance your understanding of the tool and its mechanisms.

Transmission of rotation

Unlike conventional rotary hammers, the armature shaft in the Model DH 24PB2 is in parallel with the tool

shaft - the same structure that is employed in most impact drills. This structure was adopted in order to make

the Model DH 24PB2 more compact for easier handling and operability. Thus, the appearance of the Model

DH 24PB2 is similar to that of an impact drill. The rotation of the armature is transmitted to the second shaft

via the first gear, and causes it to rotate. The second pinion provided on the second shaft engages the second

gear mounted on the outer circumference of the cylinder. The cylinder is coupled to the second gear by

means of a slip mechanism, and they rotate together. The end of the cylinder also functions as the drill bit

retainer. The cylinder is key-connected to the inserted drill bit by means of two key rails, and transmits rotation

to the drill bit. A steel ball is used to prevent the bit from falling.

Содержание DH24PB2

Страница 39: ......