dIXEL

Operating Manual

1592020130

1592020130 XR03_04CX GB 16.01.07.doc

XR03CX – XR04CX

Hy Differential:

(0,1°C

÷

25°C) Intervention differential for set point. Compressor Cut IN is SET

POINT + differential (Hy). Compressor Cut OUT is when the temperature reaches the set point.

LS Minimum

SET

POINT: (-55°C÷SET/-58°F÷SET): Sets the minimum value for the set point..

US Maximum SET POINT: (SET÷99°C/ SET÷99°F). Set the maximum value for set point.

ot First probe calibration: (-9.9÷9.9°C) allows to adjust possible offset of the first probe.

P2 Evaporator probe presence: n= not present; y= the defrost stops by temperature. (Only

XR04CX)

oE Second probe calibration: (-9.9÷9.9°C) allows to adjust possible offset of the second probe.

(Only XR04CX)

od Outputs activation delay at start up: (0÷99min) This function is enabled at the initial start up of

the instrument and inhibits any output activation for the period of time set in the parameter.

AC Anti-short cycle delay: (0÷50 min) minimum interval between the compressor stop and the

following restart.

Cy Compressor ON time with faulty probe: (0÷99 min) time during which the compressor is active

in case of faulty thermostat probe. With Cy=0 compressor is always OFF.

Cn Compressor OFF time with faulty probe: (0÷99 min) time during which the compressor is OFF

in case of faulty thermostat probe. With Cn=0 compressor is always active.

CH Kind of Action (Only XR03CX): cL= cooling action; Ht = heating action;

DISPLAY

CF Measurement

unit:

(°C÷°F) °C =Celsius; °F =Fahrenheit. WARNING: When the measurement

unit is changed the SET point and the values of the parameters Hy, LS, US, oE, o1, AU, AL

have to be checked and modified if necessary).

rE Resolution (only for °C):(dE ÷ in) dE= decimal between -9.9 and 9.9°C; in= integer

Ld Default

display:

(P1 ÷ P2) P1= thermostat probe; P2= evaporator probe. SP=Set point (Only

XR04CX)

dy Display

delay:

(0

÷

15 min.) when the temperature increases, the display is updated of 1 °C/1°F

after this time.

DEFROST

td Defrost

type:

(EL – in) EL= electrical heater, compressor OFF; in= hot gas, compressor ON;

dE Defrost termination temperature (Only XR04CX): (-50÷50°C) if P2=Y it sets the temperature

measured by the evaporator probe, which causes the end of defrost.

id Interval between defrost cycles: (0÷99 ore) Determines the time interval between the

beginning of two defrost cycles.

Md Maximum length for defrost: (0÷99 min. with 0 no defrost) when P2=n, (not evaporator probe:

timed defrost) it sets the defrost duration, when P2 = y (defrost end based on temperature) it sets

the maximum length for defrost.

dd Start defrost delay: ( 0÷99min) This is useful when different defrost start times are necessary to

avoid overloading the plant.

dF Display

during

defrost:

(rt / it / St / dF) rt= real temperature; it= start defrost temperature; SP=

SET-POINT; dF= label dF.

dt Drip time: (0÷99 min) time interval between reaching defrost termination temperature and the

restoring of the control’s normal operation. This time allows the evaporator to eliminate water

drops that might have formed due to defrost.

dP Defrost at power –on: (y÷n) y= at power on defrost starts; n= defrost doesn’t start at power-on

ALARMS

AU Maximum temperature alarm: (AL÷99°C) when this temperature is reached the alarm is

enabled, after the “Ad” delay time.

AL Minimum temperature alarm: (-55÷AU°C) when this temperature is reached the alarm is

enabled, after the “Ad” delay time.

Ad Temperature

alarm

delay: (0÷99 min) time interval between the detection of an alarm condition

and alarm signalling.

dA Exclusion of temperature alarm at startup: (0÷99 min) time interval between the detection of

the temperature alarm condition after instrument power on and alarm signalling.

tb Silencing

buzzer

(n-y):(Only XR03CX) n= silencing disabled, alarm relay stays on till alarm

conditions lasts; y= silencing enabled: alarm relay is switched OFF by pressing a key during an

alarm;

o1 Auxiliary relay configuration (dF/Fn/AL/AU/db): (Only XR03CX) dF= defrost; Fn= Fans; AL=

Alarm; AU= auxiliary; db= neutral zone;

AP Alarm relay polarity (cL-OP): (Only XR03CX) cL= when active is closed; OP= when active is

opened

DIGITAL INPUT (Only XR03CX)

iP Digital input polarity: (oP ÷ cL) oP= activated by closing the contact; cL= activated by opening

the contact;

iF Digital input configuration: (EA/bA/do/dF/Au/Hc) EA= external alarm: “EA” message is

displayed; bA= serious alarm “CA” message is displayed; do= door switch function; dF= defrost

activation; Au =not used; Hc= inversion of the kind of action;

di Digital input delay: (0÷99 min) with iF=EA or bA delay between the detection of the external

alarm condition and its signalling. . With iF=do it represents the delay to activate the door open

alarm.

dC Compressor and fan status when open door: (no/Fn/cP/Fc): no= normal; Fn = Fans OFF; cP

=Compressor OFF; Fc = Compressor and fans OFF;

rd Regulation with door open: (n÷y) n = no regulation if door is opened; Y= when di is elapsed

regulation restarts even if door open alarm is present;

OTHER

d1 Thermostat probe display (read only)

d2 Evaporator probe display (read only) (Only XR03CX)

Pt Parameter code table

rL Software release

8. DIGITAL INPUTS

The free voltage digital input is programmable in different configurations by the “iF” parameter.

DOOR SWITCH (iF=do)

It signals the door status and the corresponding relay output status through the “dC” parameter: no =

normal (any change); Fn = Fan OFF; CP = Compressor OFF; FC = Compressor and fan OFF.

Since the door is opened, after the delay time set through parameter “di”, the door alarm is enabled,

the display shows the message “dA” and the regulation restarts if rd = y. The alarm stops as soon

as the external digital input is disabled again. With the door open, the high and low temperature alarms

are disabled.

EXTERNAL ALARM (iF=EA)

As soon as the digital input is activated the unit will wait for “di” time delay before signalling the “EA”

alarm message. The outputs status don’t change. The alarm stops just after the digital input is de-

activated.

SERIOUS ALARM (iF=bA)

When the digital input is activated, the unit will wait for “di” delay before signalling the “CA” alarm

message. The relay outputs are switched OFF. The alarm will stop as soon as the digital input is de-

activated.

SWITCHING SECOND RELAY ON (iF=Au)

When o1=Au it switches on and off the second relay.

START DEFROST (iF=dF)

It starts a defrost if there are the right conditions. After the defrost is finished, the normal regulation will

restart only if the digital input is disabled otherwise the instrument will wait until the “dd” safety time is

expired.

INVERSION OF THE KIND OF ACTION: HEATING - COOLING (iF=Hc)

This function allows to invert the regulation of the controller: from cooling to heating and viceversa.

9. INSTALLATION AND MOUNTING

Instrument XR03CX and XR04CX shall be mounted on vertical

panel, in a 29x71 mm hole, and fixed using the special bracket

supplied.

The temperature range allowed for correct operation is 0

÷

60 °C.

Avoid places subject to strong vibrations, corrosive gases,

excessive dirt or humidity. The same recommendations apply to

probes. Let air circulate by the cooling holes.

10. ELECTRICAL CONNECTIONS

The instrument is provided with screw terminal block to connect cables with a cross section up to 2,5

mm

2

. Before connecting cables make sure the power supply complies with the instrument’s

requirements. Separate the probe cables from the power supply cables, from the outputs and the

power connections. Do not exceed the maximum current allowed on each relay, in case of heavier

loads use a suitable external relay.

1.1

PROBES

The probes shall be mounted with the bulb upwards to prevent damages due to casual liquid

infiltration. It is recommended to place the thermostat probe away from air streams to correctly

measure the average room temperature. Place the defrost termination probe among the evaporator

fins in the coldest place, where most ice is formed, far from heaters or from the warmest place during

defrost, to prevent premature defrost termination.

11. HOW TO USE THE HOT KEY

1.2

HOW TO PROGRAM THE HOT KEY FROM THE INSTRUMENT (UPLOAD)

1.

Program one controller with the front keypad.

2.

When the controller is ON, insert the “Hot key” and push key; the "uP" message appears

followed a by flashing “Ed”

3.

Push “SET” key and the “Ed” will stop flashing.

4.

Turn OFF the instrument remove the “Hot Key”, then turn it ON again.

NOTE: the “Er” message is displayed for failed programming. In this case push again o key if you want

to restart the upload again or remove the “Hot key” to abort the operation.

1.3

HOW TO PROGRAM AN INSTRUMENT USING HOT KEY (DOWNLOAD)

1.

Turn OFF the instrument.

2.

Insert a programmed “Hot Key” into the 5 PIN receptacle and then turn the Controller ON.

3.

Automatically the parameter list of the “Hot Key” is downloaded into the Controller memory, the

“do” message is blinking followed a by flashing “Ed”.

4.

After 10 seconds the instrument will restart working with the new parameters.

5.

Remove the “Hot Key”..

NOTE: the “Er” message is displayed for failed programming. In this case push again o key if you want

to restart the upload again or remove the “Hot key” to abort the operation.

12. ALARM

SIGNALLING

Mess. Cause

Outputs

"P1"

Room probe failure

Compressor output according to “Cy” e “Cn”

"P2"

Evaporator probe failure

Defrost end is timed (Only XR04CX)

"HA"

Maximum temperature alarm

Outputs unchanged

"LA"

Minimum temperature alarm

Outputs unchanged

“EA” External

alarm

Outputs

unchanged

“CA”

Serious external alarm

All outputs OFF.

“dA”

Door Open

Compressor and fans restarts

1.4

ALARM RECOVERY

Probe alarms P1” and “P2” start some seconds after the fault in the related probe; they automatically

stop some seconds after the probe restarts normal operation. Check connections before replacing the

probe. Temperature alarms “HA” and “LA” automatically stop as soon as the temperature returns to

normal values.

Alarms “EA” and “CA” (with iF=bA) recover as soon as the digital input is disabled.

13. TECHNICAL

DATA

Housing: self extinguishing ABS.

Case: frontal 32x74 mm; depth 60mm;

Mounting: panel mounting in a 71x29mm panel cut-out

Содержание OWZA

Страница 2: ...ii ...

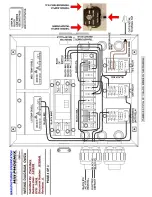

Страница 15: ...APPENDIX A DOMESTIC WIRING DIAGRAM ...

Страница 16: ......

Страница 17: ......

Страница 18: ......

Страница 19: ......

Страница 20: ...APPENDIX B EXPORT WIRING DIAGRAM ...

Страница 21: ......

Страница 22: ......

Страница 23: ......

Страница 24: ......

Страница 25: ...APPENDIX C CONTROLLER INFORMATION ...

Страница 29: ...APPENDIX D USER SET POINTS ...

Страница 30: ......