dIXEL

Operating Manual

1592020130

1592020130 XR03_04CX GB 16.01.07.doc

XR03CX – XR04CX

DIGITAL CONTROLLER

XR03CX – XR04CX

1. CONTENTS

1.

Contents __________________________________________________________________________ 1

2.

General warnings ___________________________________________________________________ 1

3.

General description __________________________________________________________________ 1

4.

Regulation_________________________________________________________________________ 1

5.

Defrost ___________________________________________________________________________ 1

6.

Front panel commands _______________________________________________________________ 1

7.

Parameters ________________________________________________________________________ 1

8.

Digital inputs _______________________________________________________________________ 2

9.

Installation and mounting _____________________________________________________________ 2

10.

Electrical connections ________________________________________________________________ 2

11.

How to use the hot key _______________________________________________________________ 2

12.

Alarm signalling_____________________________________________________________________ 2

13.

Technical data______________________________________________________________________ 2

14.

Connections _______________________________________________________________________ 3

15.

Default setting values ________________________________________________________________ 3

2. GENERAL WARNINGS

PLEASE READ BEFORE USING THIS MANUAL

1.

This manual is part of the product and should be kept near the instrument for easy and quick

reference.

2.

The instrument shall not be used for purposes different from those described hereunder. It

cannot be used as a safety device.

3.

Check the application limits before proceeding.

SAFETY PRECAUTIONS

•

Check the supply voltage is correct before connecting the instrument.

•

Do not expose to water or moisture: use the controller only within the operating limits avoiding

sudden temperature changes with high atmospheric humidity to prevent formation of

condensation

•

Warning: disconnect all electrical connections before any kind of maintenance.

•

Fit the probe where it is not accessible by the End User. The instrument must not be opened.

•

In case of failure or faulty operation send the instrument back to the distributor or to “Dixell

S.p.A.” (see address) with a detailed description of the fault.

•

Consider the maximum current which can be applied to each relay (see Technical Data).

•

Ensure that the wires for probes, loads and the power supply are separated and far enough from

each other, without crossing or intertwining.

•

In case of applications in industrial environments, the use of mains filters (our mod. FT1) in

parallel with inductive loads could be useful.

3. GENERAL DESCRIPTION

The XR03CX, in 32

×

74x50mm short format, is microprocessor based controller suitable for applications on

normal temperature refrigerating units. It provides two relay output: one for compressor and the other one for

alarm signalling or as auxiliary output. It provides an NTC probe input and a digital input for alarm signalling,

for switching the auxiliary output or for start defrost. The instrument is fully configurable through special

parameters that can be easily programmed through the keyboard or the by HOTKEY.

The XR04CX, in 32

×

74x50mm short format, is microprocessor based controller suitable for applications on

normal or low temperature refrigerating units. It provides two relay output: one for compressor and the other

one for defrost. It provides two NTC probe inputs, one for room temperature and other one to control defrost

termination. The instrument is fully configurable through special parameters that can be easily programmed

through the keyboard or the by HOTKEY.

4. REGULATION

The regulation is performed according to

the temperature measured by the

thermostat probe with a positive

differential from the set point: if the

temperature increases and reaches set

point plus differential the compressor is

started and then turned off when the

temperature reaches the set point value

again.

In case of fault in the thermostat probe the start and stop of the compressor are timed through

parameters “Cy” and “Cn”.

5. DEFROST

XR03CX

Defrost is performed through a simple stop of the compressor. Parameter “id” controls the interval

between defrost cycles, while its length is controlled by parameter “Md”.

XR04CX

Two defrost modes are available through the “td” parameter:

•

td=EL

→

defrost through electrical heater (compressor OFF)

•

td=in

→

hot gas defrost (compressor ON).

Other parameters are used to control the interval between defrost cycles (id) ), its maximum length

(Md) and two defrost modes: timed or controlled by the evaporator’s probe. At the end of defrost

dripping time is started, its length is set in the dt parameter. With dt=0 the dripping time is disabled.

6. FRONT PANEL COMMANDS

To display target set point, in

programming mode it selects a

parameter or confirm an

operation

To start a manual defrost

In programming mode it

browses the parameter codes

or increases the displayed

value

AUX

In programming mode it

browses the parameter codes

or decreases the displayed

value

KEYS COMBINATION

+

To lock or unlock the keyboard

+

To enter in programming mode

+

To return to room temperature display

LED

MODO

SIGNIFICATO

On

Compressore enabled

Flashing

Anti short cycle delay enabled (AC parameter)

On

Defrost in progress

Flashing

Dripping in progress

On

Measurement unit

Flashing

Programming mode

On

Measurement unit

Flashing

Programming mode

HOW TO SEE THE SET POINT

1.

Push and immediately release the SET key, the set point will be showed;

2.

Push and immediately release the SET key or wait about 5s to return to normal visualisation.

HOW TO CHANGE THE SETPOINT

1.

Push the SET key for more than 2 seconds to change the Set point value;

2.

The value of the set point will be displayed and the “°C” or “°F” LED starts blinking;

3.

To change the Set value push the o or n arrows within 10s.

4.

To memorise the new set point value push the SET key again or wait 10s.

HOW TO START A MANUAL DEFROST

Push the DEF

key for more than 2 seconds and a manual defrost will start

HOW TO CHANGE A PARAMETER VALUE

To change the parameter’s value operate as follows:

1.

Enter the Programming mode by pressing the SET+

keys for 3s (“°C” or “°F” LED starts

blinking).

2.

Select the required parameter. Press the “SET” key to display its value

3.

Use or to change its value.

4.

Press “SET” to store the new value and move to the following parameter.

To exit: Press SET+ or wait 15s without pressing a key.

NOTE: the set value is stored even when the procedure is exited by waiting the time-out to expire.

HIDDEN MENU

The hidden menu includes all the parameters of the instrument.

HOW TO ENTER THE HIDDEN MENU

1.

Enter the Programming mode by pressing the SET+

keys for 3s (“°C” or “°F” LED starts

blinking).

2.

Released the keys, then push again the SET+

keys for more than 7s. The L2 label will be

displayed immediately followed from the Hy parameter.

NOW YOU ARE IN THE HIDDEN MENU.

3.

Select the required parameter.

4.

Press the “SET” key to display its value

5.

Use or to change its value.

6.

Press “SET” to store the new value and move to the following parameter.

To exit: Press SET+ or wait 15s without pressing a key.

NOTE1: if none parameter is present in L1, after 3s the “nP” message is displayed. Keep the keys

pushed till the L2 message is displayed.

NOTE2: the set value is stored even when the procedure is exited by waiting the time-out to expire.

HOW TO MOVE A PARAMETER FROM THE HIDDEN MENU TO THE FIRST

LEVEL AND VICEVERSA.

Each parameter present in the HIDDEN MENU can be removed or put into “THE FIRST LEVEL” (user

level) by pressing SET+ . In HIDDEN MENU when a parameter is present in First Level the decimal

point is on.

TO LOCK THE KEYBOARD

•

Keep pressed for more than 3s the and keys.

•

The “OF” message will be displayed and the keyboard will be locked. If a key is pressed more

than 3s the “OF” message will be displayed.

TO UNLOCK THE KEYBOARD

Keep pressed together for more than 3s the and keys till the “on” message will be displayed.

7. PARAMETERS

REGULATION

Содержание OWZA

Страница 2: ...ii ...

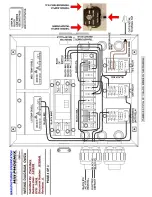

Страница 15: ...APPENDIX A DOMESTIC WIRING DIAGRAM ...

Страница 16: ......

Страница 17: ......

Страница 18: ......

Страница 19: ......

Страница 20: ...APPENDIX B EXPORT WIRING DIAGRAM ...

Страница 21: ......

Страница 22: ......

Страница 23: ......

Страница 24: ......

Страница 25: ...APPENDIX C CONTROLLER INFORMATION ...

Страница 29: ...APPENDIX D USER SET POINTS ...

Страница 30: ......