❑

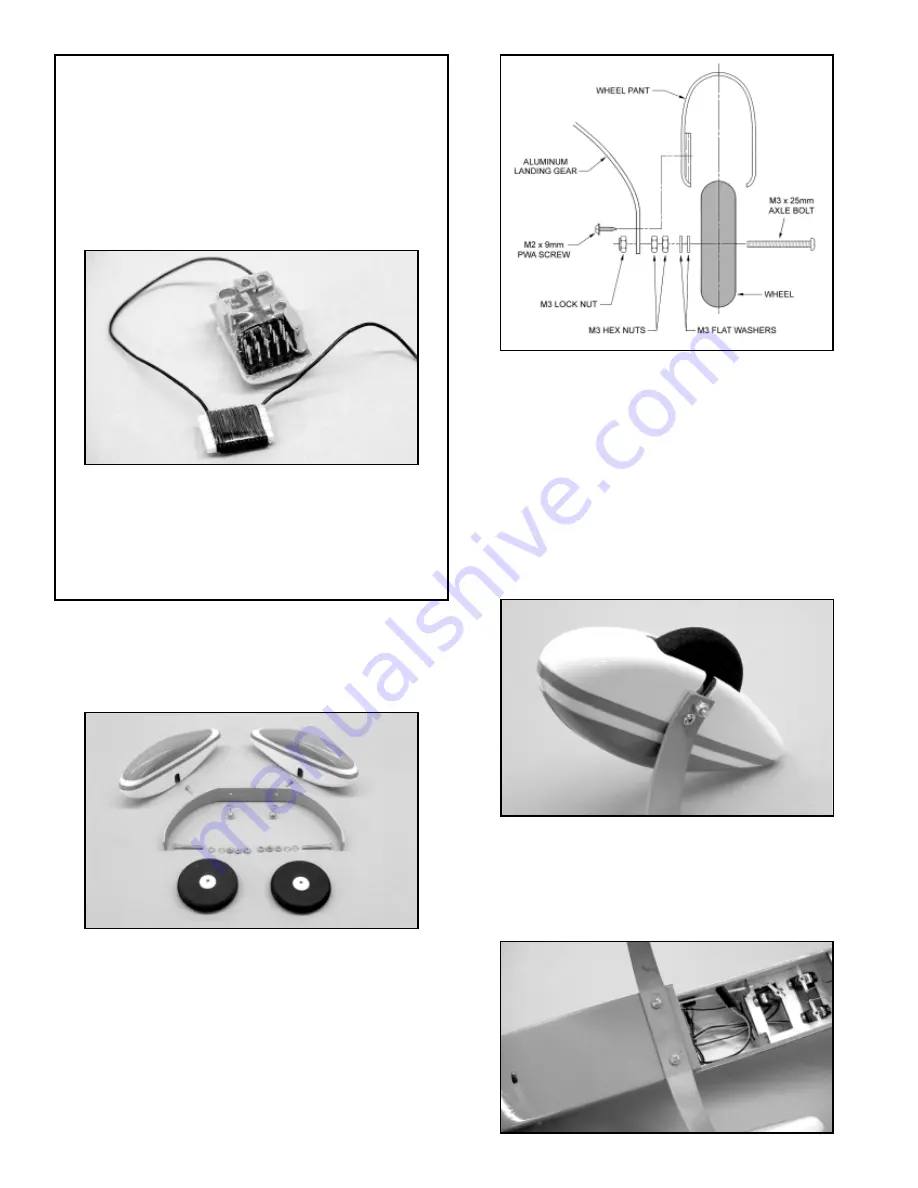

2) The Wheel Pants are now installed to the aluminum main

landing gear. Note that in side view, the landing gear is tapered

on one edge. The front or leading edge of the landing gear is the

untapered edge. Prepare the mounting holes in each wheel pant

by drilling a small diameter pilot hole (.052, #55 bit) through the

factory mark in the pant and the plywood pad inside. Mount the

pant to the landing gear using a 9mm PWA screw. Mount the

remaining pant in the same manner. After establishing the threads

with the mounting screws, we suggest removing the screws and

"hardening" the threads in each wheel pant with a small drop of

thin CA glue. After the glue sets, re-establish the threads once

again with the screws. This protects the threads from fuel damage

and makes them more resistant to stripping.

❑

3) The main landing gear assembly is now mounted to the

bottom of the fuselage, using the two M3 x 10mm PWA bolts

and the two M3 Split Ring washers provided.

It is highly

recommended that you first apply a small amount of non-

permanent thread locking compound, such as Loctite

®

#242

"Blue", to the bolt threads.

LANDING GEAR AND WHEEL PANTS:

From the kit contents, locate the bag containing the two Wheel

Pants and the bag containing the aluminum Main Landing Gear,

the Main Wheels, and the smaller bag of Mounting Hardware.

❑

1) Slide one of the M3 x 2mm Axle Bolts through one of the

main wheels. One the other side of the wheel, slide two M3 Flat

Washers in place. Thread one of the M3 Hex Nuts in place almost

up to the wheel hub. Thread a second M3 Hex Nut in place up to

the first nut. Use pliers or a metric box end wrench to hold one of

the M3 nuts while firmly tightening the second nut to it - make sure

the wheel turns freely. Slide the exposed end of the M3 Axle Bolt

through the bottom hole in the aluminum Main Landing Gear.

Start to thread one of the M3 Lock Nuts onto the Axle Bolt. Hold

the nut firmly with pliers or a wrench and use a screwdriver to

tighten the axle bolt assembly firmly in place to the landing gear.

Repeat this process with the remaining wheel.

12

MODELER'S TIP (continued): We made our "bobbin" from a

piece of 3/32" x 3/4" x 1-1/4" balsawood. From the receiver,

measure the antenna out to 4-1/2" - no closer. This is the point

to start neatly wrapping the antenna wire around the bobbin. Do

not cross the wrapped antenna wire, simply lay it neatly next to

each strand. Wrapping the antenna wire 12 - 14 times around

a bobbin this size shortens its overall length by about 11". Hold

the now wrapped antenna wire to the bobbin with a length of

clear tape. Now when you install the receiver into the fuselage,

you will have a much more reasonable length of antenna wire to

work with at the rear.

What will this procedure do to the range of your receiver? The

answer is that you will lose some amount of range but not

enough to effect the overall safe operation of the model. This is

because a small R/C model is rarely flown to extreme distances

for the simple reason that you can no longer see it. Since you

would never do this, some loss of range is more than acceptable

for a small model.