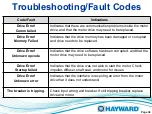

Troubleshooting/Fault Codes

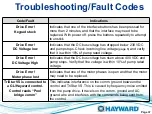

Code/Fault

Indications

Drive Error!

Drive is Overheated

Indicates that the internal components of the drive have

become overheated. Motor airflow path should be checked.

Check fan and shroud for blockage.

Drive Error!

Processor failed

Indicates that there is a problem with the processor in the motor

drive, and that the motor drive may need to be replaced.

Drive Error!

Drive Overload

Indicates that the motor is drawing excessive current. Check

impeller, diffuser and shaft seals for issues.

Page 36

This guide will cover only those problems with the VSC and Motor. All other pump problems, including

seals, gaskets, impellers, etc., along with priming problems are addressed in the owners manual.

Do not attempt to remove the drive from motor, or service the motor.

The EcoStar display is not compatible with the TriStar VS.

For each code or fault, always reboot the pump to attempt to clear the error code or fault

first.