USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Page 17 of 36

Super Pump VS Pump

IS2603VSP Rev-A

5.4.

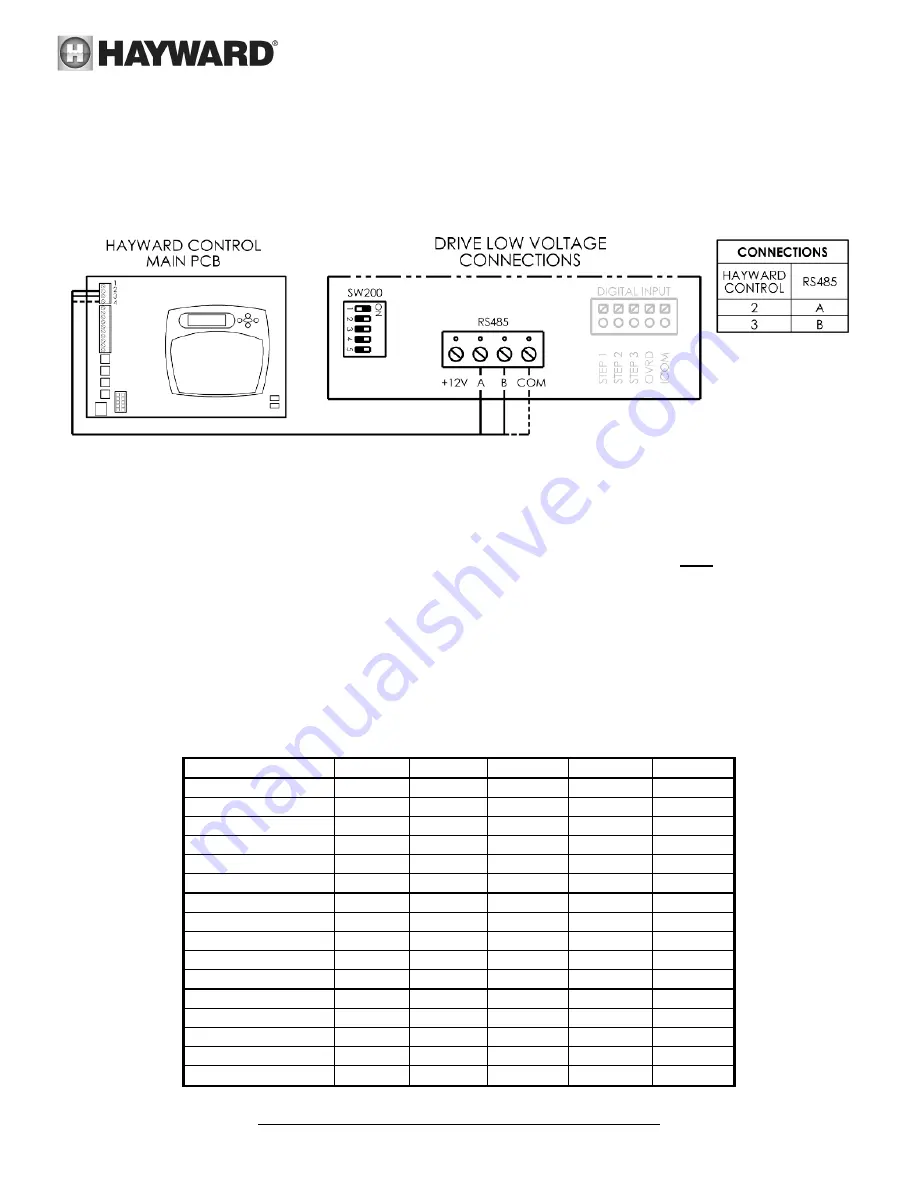

Hayward Automation Control Wiring (Optional, for remote control of pump

speed)

Note: For software compatible Hayward controls only. Existing user interface wiring connections must be

removed from 4-position terminal block connector and must be covered/secured inside wiring compartments

prior to making wiring connections shown below.

Figure 5.4 1

The Super Pump VS pump can communicate with and be controlled by Hayward pool controls such as OmniLogic™,

ProLogic®, E-Command® 4, and OnCommand®. Minimum software revision requirements: OmniLogic R1.0.0,

ProLogic 3.00, OnCommand 1.00, E-Command 2.65, E-Command 4 2.80, AquaLogic 2.65, and AquaPlus 2.65. To

determine Hayward control software revision, consult the appropriate Hayward pool control installation manual or visit

our website at www.haywardpool.com. Connection wire must be rated for a minimum of 300V, and may be up to 500

feet in length. Use removable 4-position terminal block connector for wiring connection to motor drive PCB, taking care

to note the wire colors and corresponding numbers next to the connectors.

Terminal block must be installed with

screws facing up to ensure proper connection.

When communicating with OmniLogic, the HUA (Hayward Unique Address) is used for communication. For all Hayward

controls other than OmniLogic, the pump address must be set using the SW200 DIP switch on the drive PCB. To

determine which address should be used, consult the appropriate Hayward Pro Logic pool control installation manual,

or visit our website at www.haywardpool.com. Pump addresses are set according to the table below.

Note:

If communication issues are encountered, a third wire may be connected between terminal “4” at the pool

control and terminal “COM” at the motor drive to help improve signal quality.

SW200 DIP SWITCH STATUS

PUMP ADDRESS

#1

#2

#3

#4

#5

Pool Filter OFF

OFF

OFF

OFF

OFF

Aux 1 / Spa Filter OFF

ON

OFF

OFF

OFF

Aux 2

OFF

OFF

ON

OFF

OFF

Aux 3

OFF

ON

ON

OFF

OFF

Aux 4

OFF

OFF

OFF

ON

OFF

Aux 5

OFF

ON

OFF

ON

OFF

Aux 6

OFF

OFF

ON

ON

OFF

Aux 7

OFF

ON

ON

ON

OFF

Aux 8

OFF

OFF

OFF

OFF

ON

Aux 9

OFF

ON

OFF

OFF

ON

Aux 10

OFF

OFF

ON

OFF

ON

Aux 11

OFF

ON

ON

OFF

ON

Aux 12

OFF

OFF

OFF

ON

ON

Aux 13

OFF

ON

OFF

ON

ON

Aux 14

OFF

OFF

ON

ON

ON

Lights Button

OFF

ON

ON

ON

ON