03/20

Model H1001.8/H1001.8HPS

Page 2 of 7

RECOMMENDED TOOLS

: Hack saw, pipe joint sealant, screwdriver, level, 12" adjustable

wrench, 10" pipe wrench, 3/32” and 5/32 “ hex key wrench, 9/16”, 1/2", 7/16” socket wrench

or open end wrench.

LOCATION OF UNIT:

The Model H1001.8/H1001.8HPS Cooler is a wheelchair accessible

drinking facility. The height dimensions shown, meet current ADA requirements. When

installing this unit, local, state or federal codes should be adhered to. If height other than

shown is required, then dimensions must be adjusted accordingly.

SUPPLY LINE

: The minimum recommended line size is 1/2

“IPS with 30-90 psi (2-6 ATM)

flowing pressure. Where sediment or mineral content is a problem, an inlet filter is

recommended.

PLUMBING CONNECTIONS:

Inlet is 3/8” O.D. tube. Waste outlet is 1-1/4” O.D. tube.

ELECTRICAL CONNECTIONS

: 115VAC, 60HZ, 4.7 AMPS. Chiller wired direct to incoming

line, by others.

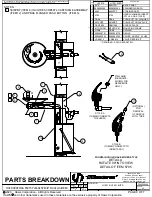

PARTS LIST

MODEL PACKAGE

QUANTITY

ITEMS INCLUDED

MTGFR.SM

1

Mounting Frame (Required - Sold

Separately

3

#10 Sheet Metal Screws

HCR8

1

Chiller

H1001.8/H1001.8HPS

1

Bowl Assembly

1

Package supply tubing and two (2)

fittings

1

Grille

1

Package of two each-grille attachment

clips, clip nuts, #10 sheet metal screws

and 6-32 screws

4

5/16 -18 retainer nuts

4

5/16

– 18 x 1 hex head screws

1

Waste elbow 1-

1/4” O.D.

SHOULD YOU EXPERIENCE DIFFICULTY WITH THE INSTALLATION OF THIS

MODEL PLEASE CALL:

TECHNICAL SUPPORT:

1-800-766-5612

FOR CUSTOMER SERVICE:

1-888-640-4297