MODU-FIRE® Forced Draft Gas-Fired Boiler

18

3.5.3.2.3 Interior Component Installation Clearances

All vent system components shall be installed so as to maintain the vent manufacturer’s required minimum clear-

ances to combustibles and non-combustibles.

3.5.3.3 Flue Connection

The boiler vent should not be connected into any portion of another me-

chanical draft system without consulting the vent manufacturer. This boiler operates under a positive

vent pressure. The boiler shall not be connected to any part of a vent system serving a Category I or

II appliance, nor shall a Category I or II appliance be connected to any part of the vent system serving

this appliance. Improper interconnection of venting systems may result in leakage of flue gases into

occupied spaces.

NOTICE! Make sure that the weight of the vent is not supported by the boiler vent collar. The col-

lar is not designed to support the weight of the vent. The vent system shall be supported in ac-

cordance with the manufacturer’s instructions. Horizontal vent sections shall be supported in a man-

ner to prevent sags or low spots where condensate can collect. Structural supports must be con-

nected to building elements of sufficient strength to withstand the weight of the vent system and any

bending forces imposed by the venting system.

The 750,000 Btu & 1,000,000 Btu boilers have 6” OD connections for the vent. If venting design permits, this con-

nection may be reduced to 4” or 5” diameter.

The 1,500,000 Btu & 2,000,000 Btu boilers have 8” OD connections for the vent. If venting design permits, this

connection may be reduced to 6” diameter.

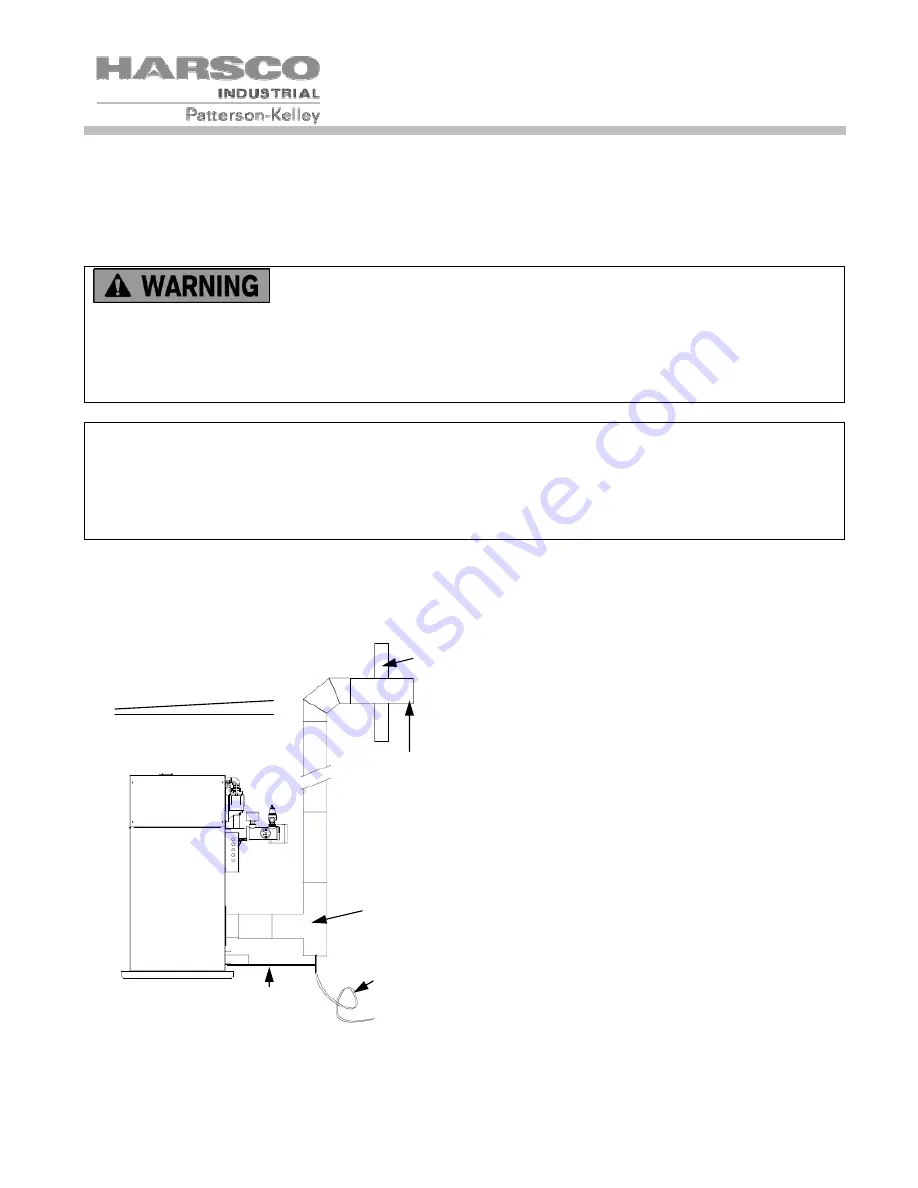

The connection from the boiler to the vent should

be made using an adapter that is designed to fit

the OD of the boiler outlet. The vent

manufacturer’s adapter must be sealed to the

boiler outlet with sealant listed for use with the

vent material. The connection from the boiler to

the vent should be as direct as possible and the

upward slope of any horizontal breaching should

be at least ¼ inch per linear foot. Provisions must

be made for supports to prevent contact of the

vent with combustible surfaces.

The complete exhaust with drain system is shown

in the figure. The appliance connector should

incorporate provisions to drain condensate formed

in the vent system. The first turn from horizontal

to vertical should be made with either a standard

tee with condensate drain cap or an elbow

with

an

“inline” drain installed immediately above the

elbow. The condensate drain line from the boiler

must be connected to the stack drain upstream of

the stack trap using a material that will withstand

condensate corrosion and a maximum

temperature of 400°F. The stack trap shall have a

minimum height of 4 inches. The condensate must be routed to a suitable drain that complies with all local codes.

Boiler Outlet

Building

Sidewall

See 3.5.3.4 for

termination details

Pitch Towards Boiler

¼” per foot min

Tee

w/Drain

Stack Drain

w/Trap

4” min height

Boiler Condensate Drain

(Stainless Steel or Hi Temp

Silicone Tubing)

Содержание MODU-FIRE FORCED DRAFT N750

Страница 45: ...MODU FIRE Forced Draft Gas Fired Boiler 45 6 1 5 Main Control Panel Point to Point Left Side Alarm Flame Enable...

Страница 46: ...MODU FIRE Forced Draft Gas Fired Boiler 46 6 1 6 Main Control Panel Point to Point Right Side...

Страница 47: ...MODU FIRE Forced Draft Gas Fired Boiler 47 6 1 7 Junction Box Point to Point and Customer Connections...

Страница 48: ...MODU FIRE Forced Draft Gas Fired Boiler 48 6 1 8 Customer Connections Details...