7 - Fault finding

87

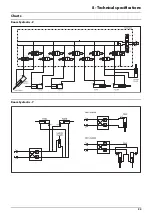

Hydraulic system - Z model

Hydraulic system - Y model

FAULT

PROBABLE CAUSE

CONTROL/REMEDY

No boom movements when activated.

Insufficient hydraulic pressure.

Check oil pressure.

Check tractor hydraulic oil level.

Insufficient oil supply.

Oil flow must be min. 25 l/min. and max. 130 l/min.

Check tractor hydraulic oil level.

Blown fuse(s).

Check / replace fuse in junction box.

Bad / corroded electrical connections.

Check / clean connections, multi plugs etc.

Insufficient power supply.

Voltage on activated solenoid valve must be more

than 8 volts.

Use wires of at least 4 mm for power supply.

Defect relay / diodes in junction box.

Check relays, diodes and soldering at PCB in junction

box. LED diodes indicate boom functions.

Clogged restrictors in bypass block.

Remove and clean restrictors in bypass block (See

hydraulic diagram). Change hydraulic oil + filter.

Wrong polarity.

Check polarity. Red positive (+) Black negative (-).

ParaLift lock does not lock.

Boom lift raises to max. position when tractor

hydraulics are engaged.

Back pressure in return line exceeds 15 bar.

Connect the return line with free flow to hydraulic oil

reservoir.

Divide return line in two and lead return oil back to

reservoir via two spool valves.

Oil heats up in Closed Centre systems.

Bypass valve does not close properly.

Check / close (screw in) by-pass valve.

Internal leaks in flow regulator.

Replace flow regulator O-rings and backup rings.

Replace flow regulator.

Individual ram does not move.

Clogged restrictor.

Dismantle and clean restrictor.

FAULT

PROBABLE CAUSE

CONTROL/REMEDY

Boom slow/eradic.

Air in system.

Loosen ram connection and activate hydraulics until

oil flow has no air in it (not whitish).

Regulation valve incorrectly set.

Open or close until desired speed is achieved

(clockwise = less speed).

Remember oil must be at operating temperature.

Insufficient hydraulic pressure.

Check output pressure of tractor hydraulics. Minimum

for sprayer is 170 bar.

Insufficient amount of oil in tractor reservoir.

Check and top if needed.

Ram not functioning.

Restrictor or regulation valve blocked.

Secure boom. Dismantle and clean.

Hydraulic system fold/tilt functions will not operate. Power supply.

Check for proper 12V power supply.

One function (fold or tilt) will not operate.

Various.

Check for defective switch(s).

Check continuity of cables.

Check for operation of applicable solenoid (coil not

activating or plunger stuck).

Check for short circuit in wiring junction box at rear of

sprayer.

Dirt in the restrictor port of the cylinder.

Multiple hydraulic functions with one switch

activated.

Various.

Check for correct solenoid electric/hydraulic hook-up.

Check for short circuit in wiring in the junction box at

rear of sprayer.

Содержание RANGER EAGLE

Страница 8: ...1 EC Declaration 8 ...

Страница 12: ...2 Safety notes 12 ...

Страница 26: ...3 Description 26 ...

Страница 40: ...4 Sprayer setup 40 ...

Страница 60: ...5 Operation 60 ...

Страница 62: ...6 Maintenance 62 Trailer lubrication oiling plan P T O lubrication oiling plan Serie 100 type P T O shaft C 50 ...

Страница 84: ...6 Maintenance 84 ...

Страница 95: ...8 Technical specifications 95 Charts Boom hydraulic Z Boom hydraulic Y ...

Страница 96: ...8 Technical specifications 96 ...

Страница 100: ...HARDI INTERNATIONAL A S Helgeshøj Allé 38 DK 2630 Taastrup DENMARK ...