6 - Maintenance

87

Nozzle Tubes and Fittings

Poor sealings are usually caused by:

•

Missing O-rings or gaskets

•

Damaged or incorrectly seated O-rings

•

Dry or deformed O-rings or gaskets

•

Foreign objects

In case of leaks:

DO NOT overtighten. Disassemble, check condition and position of O-

ring or gasket. Clean, lubricate and reassemble.

The O-ring must be lubricated ALL THE WAY ROUND, before fitting it on

to the nozzle tube. Use non-mineral lubricant.

For AXIAL connections, a little mechanical leverage may be used.

For RADIAL connections, only tighten by hand.

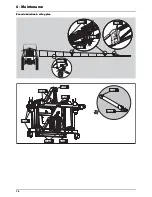

Adjustment of 3-Way Valve

The large ball valve (type s93) can be adjusted, if it is too tight to

operate - or if it is too loose (=liquid leakage).

•

Correct setting is when the valve can be operated smoothly by one

hand.

Use a suitable tool and adjust the toothed ring inside the valve as shown

on the drawing.

μ

ATTENTION! The small ball valves (type s67) cannot be adjusted.

Retighten the Frame

The frame are two sections bolted together. Also the drawbar is bolted to the frame. These bolts need to be tightened

correctly. Check regularly if bolts are tightened according to the specified torques below.

180 Nm

250 Nm

250 Nm

250 Nm

180 Nm

180 Nm

Содержание NAVIGATOR FORCE

Страница 4: ...1 EU Declaration 4 ...

Страница 12: ...2 Safety Notes 12 ...

Страница 54: ...4 Sprayer setup 54 ...

Страница 76: ...6 Maintenance 76 Boom lubrication oiling plan ...

Страница 112: ...8 Technical specifications 112 ...

Страница 116: ...Index 116 ...

Страница 118: ...HARDI INTERNATIONAL A S Herthadalvej 10 DK 4840 Nørre Alslev DENMARK ...