37

All HANBELL screw compressors are put through strict quality and performance testing prior to shipping from

the factory.

Provided that terms of payment are observed, a

two year

(

24-month) warranty

against factory defects

is offered

from the date of installation or 27 months from date of shipment.

It is a two-year warranty on the compressor until the first occurrence. The validity of the second year of

the warranty is subject to the maintenance of the compressor unit during the first year. Customers

should send a maintenance report to validate this service.

All given inspection and replacement intervals can only be guidelines.

Hanbell compressors sold by MCS, which are controlled by an MCS micro controller with software and

configuration written and tested by MCS, shall be covered under a three-year (36 months) warranty

agreement on the compressor only.

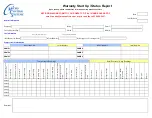

Warranty Start-up/Status Report Form(s) for each compressor(s) must be completed at time of startup

and returned within 4 weeks from shipment date of compressor(s) before the warranty will be granted.

MCS may at its option, repair or replace defective products that are under warranty.

Compressor Warranty is based on having an Over/Under Voltage Phase Protection Device installed on

the equipment.

1.1.

Warranty Maintenance

The technicians should be familiar with the Hanbell compressor before attempting any maintenance on the unit.

Periodical check and regular maintenance are very important for the long and trouble-free compressor life and

for maintaining the warranty. The content here is to help the operator and service people to know how the regu-

lar maintenance can be done and when the suitable time is for each item. Operators and service people should

follow the instructions on these pages when working on the maintenance.

Besides the regular maintenance, Technicians should check the system’s working status by noting down its

working parameters on a set schedule. Most of the time abnormal system conditions can be found via comparing

its working parameters with its daily operating data.

Compressor unit should be stopped before doing the maintenance job.

Disconnect power from unit before doing the maintenance job.

Close all the isolation valves before doing the maintenance job.

Wear safety equipment when doing the maintenance job.

Ensure adequate ventilation before doing the maintenance job.

Take safety precautions for the refrigerant used and work with care.

1.2.

Short Term Maintenance

During commissioning period or after a few hundred hours of compressor running, the following checks and

replacement shall be done in order to protect the compressor and understand the compressor’s working status.

1.2.1

Suction Strainer

The Suction strainer plays a very important role to long compressor life. In the initial commissioning, debris

24 Month Warranty

Suggestive Guidelines for Preventive Maintenance

Supersedes all other warranties

Содержание RC2-100

Страница 9: ...COMPRESSOR INSTALLATION START UP GUIDE REVISION M 9 Figure 5 A Motor Wiring ...

Страница 15: ...15 COMPRESSOR INSTALLATION START UP GUIDE REVISION M ...

Страница 16: ...16 COMPRESSOR INSTALLATION START UP GUIDE REVISION M ...

Страница 17: ...17 COMPRESSOR INSTALLATION START UP GUIDE REVISION M ...