HAMWORTHY HEATING LTD. PUREWELL AUTOMATIC IGNITION 500001035/G

5

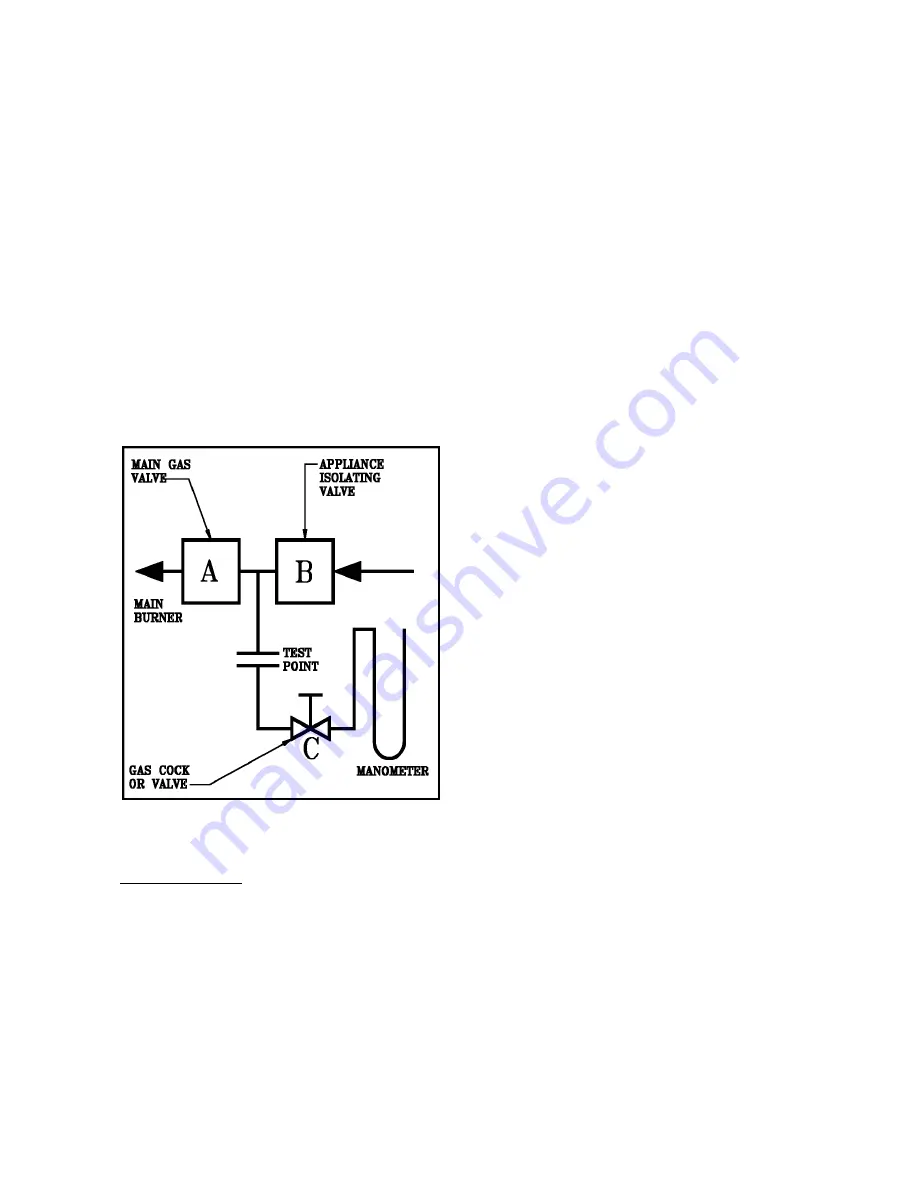

To Check Valve B

1) Turn off the electrical power and gas to the appliance.

2) Connect the manometer to gas valve test point.

3) With A, B closed open C and monitor manometer

over a 2 minute period, a rise indicates a leak on valve

B.

To Check Valve A

1) Open C.

2) Open B to produce the main gas supply pressure

between A and B.

3) Close B

4) System may be considered sound if over a period of

2 minutes any drop in pressure is less than 0.5 mbar

(0.2" wg.).

NOTE:

Allow a manometer stabilisation period of

approximately 1-minute before each 2 minute check

period. Following soundness tests close valve B and

remove manometer connections and tighten test points.

Figure No. 3 - Gas Valve leak check procedure

Note: -

Main gas supply pressure; G20 – 20mbar

G31 – 37mbar

6.0 FLUE SYSTEM

Detailed recommendations for flue systems are given in

BS 6644

, British Gas Publication

IM/11,

“Flues for

Commercial and Industrial Gas-Fired Boilers and Air

Heaters”.

The following notes are intended to give general guidance

only.

6.1

General Requirements

The Hamworthy Purewell series of boilers are designed

to be used with natural draught flues. Flue systems

should be designed in accordance

with current regulations and with reference to the British

Gas publication

IM/11

“Flues for Commercial and

Industrial Gas Fired Boilers and Air Heaters”. The

following points should be noted: -

1)

Each boiler

MUST

have its correct draught diverter

fitted in an unmodified condition before connection to

the flue system.

2)

The bottom of the flue header should be at least 500

mm above the draught diverter skirt bottom.

3)

The flue system must be self-supporting in the correct

position to avoid compression of the draught diverter

and enable its removal for boiler cleaning.

4)

Boilers should be located as near the chimney as

possible the nearest being not more than 2m (6ft) away.

5)

The flue system should be designed to achieve a

negative suction at all times at the draught diverter outlet

on all modules in a bank. For optimum performance,

draught conditions should be between -0.05 to -0.125

mbar. In the case of a single boiler installation the

minimum vertical flue height is 2m above the draught

diverter skirt. For multiple boiler installations consult

Hamworthy Heating Technical Department. In some

instances, mechanical assistance may be necessary.

The boilers are suitable for connection to a fan diluted

flue system, refer to British Gas publication

IM/11

“Flues

for Commercial and Industrial Gas Fired Boilers and

Air Heaters”.

6)

Purewell boilers are suitable for installation in a

balanced compartment in accordance with the

requirements of

BS 6644.

Consult Hamworthy Heating

Technical Department for help or assistance if in doubt.

6.2

Design Waste Gas Volume and Temperature

It is recommended that the volume and temperature of

the waste gases used for design of the flue system be

as shown in Figure No. 1.

6.3

Flue Condensation

Care should be taken to ensure that the flue is installed

in such a way that any condensation produced on start

up will drain away naturally.

6.4 Materials

Materials used for the flue system must be mechanically

robust, resistant to internal and external corrosion, non-

combustible and durable under the conditions to which

they are likely to be subjected.

6.5

Disconnection

Draught diverter models are designed to enable the

primary flue to be lifted clear of the boiler to ease

disconnection. The flue must be correctly reconnected

when servicing is complete ensuring locating bolts are

securely fitted. See

Section 13: SERVICING

for further

information.

Содержание Purewell

Страница 4: ...HAMWORTHY HEATING LTD PUREWELL AUTOMATIC IGNITION 500001035 G ii THIS PAGE LEFT INTENTIONALLY BLANK ...

Страница 19: ...HAMWORTHY HEATING LTD PUREWELL AUTOMATIC IGNITION 500001035 G 13 Figure No 7a Exploded View of Casing Set ...

Страница 28: ...HAMWORTHY HEATING LTD PUREWELL AUTOMATIC IGNITION 500001035 G 22 Figure No 10 General Layout Front View ...

Страница 40: ...HAMWORTHY HEATING LTD PUREWELL AUTOMATIC IGNITION 500001035 G 34 THIS PAGE LEFT INTENTIONALLY BLANK ...