HAMWORTHY HEATING LTD. PUREWELL PERMANENT IGNITION 500001090/B

30

APPENDIX ‘A’ TO INSTALLER’S GUIDE

INFORMATION RELATING TO PROPANE FIRING

NOTE!

LPG FUELS - IT IS STRONGLY RECOMMENDED THAT, ON LPG INSTALLATIONS, GAS DETECTION

EQUIPMENT BE FITTED. THIS EQUIPMENT SHOULD BE POSITIONED NEAR THE BOILER AND AT LOW

LEVEL. IT IS ALSO IMPORTANT THAT THE SPACE HOUSING THE BOILER IS ADEQUATELY

VENTILATED AT HIGH AND LOW LEVEL. REFER TO MAIN INSTALLER’S GUIDE.

1.0 INTRODUCTION

The operation of the Purewell range of boilers on

LPG-Propane (3

rd

family)I

3P

is similar to that on

Natural Gas (2

nd

family)I

2H

and the design and

installation details described in the main body of the

installer’s guide should be followed. There are

however, differences in the construction and setting

of the propane fired boiler which are as follows: -

a) The pilot injector marked 56/42A for Natural Gas

is replaced with an injector for Propane, marked

0.23P (perm/pilot only).

b) The main gas injectors (located in the gas

manifold) are replaced with those detailed the

Performance and General Data Information table

below.

c) The nominal gas inlet pressure for propane

should be 37mbar.

d) Relevant labels are replaced to indicate the

appropriate gas for which the boiler is set up to fire.

The following tables and paragraphs, using the

same numbering system as the main installer’s

guide, highlight the different values and procedures

to be used when firing propane, and should be

used in conjunction with the Main Installer’s Guide.

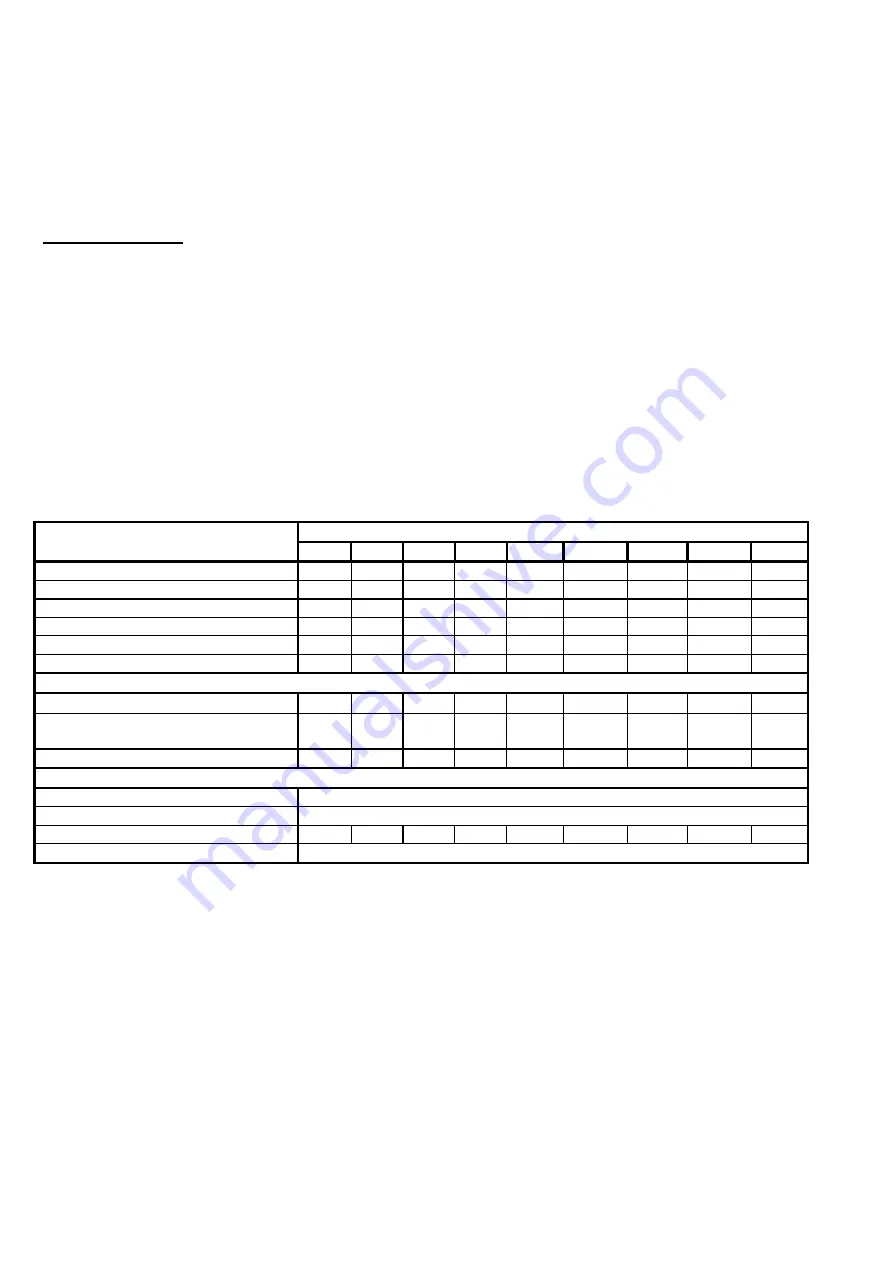

Performance and General Data Information

Model

GENERAL DATA

40

50

60

70

80

95

100

105

120

Boiler Input kW (Gross)

49.3

63.4

74.5

88.4

101.0

120.0

126.0

132.0

150.0

Boiler Input kW (Net)

45.4

58.4

68.6

81.4

93.0

110.5

116.0

121.6

138.1

Boiler Output kW

40

50

60

70

80

95

100

105

120

Gas flow rate

m

3

/h

1.9

2.4

2.8

3.3

3.8

4.5

4.7

5.0

5.7

kg/h

3.5

4.6

5.3

6.3

7.2

8.6

9.0

9.5

10.7

Gas manifold pressure

mbar

15

15

15

15

17

29

23

25

24

FLUE DATA

Approx. flue gas temp

q

C

180

190

190

200

210

200

200

210

190

Approx. flue gas vol. @

68

83

81

97

110

132

147

147

175

9% CO

2

& NTP. m

3

/h

CO

2

%

8.0

9.0

11.0

11.0

11.0

11.0

10.0

11.5

10.0

GAS DATA

Nominal gas inlet pressure

mbar

37

Maximum gas inlet pressure

mbar

45

Injector marking/ Dia.

mm

2.1

2.3

2.6

2.8

2.9

2.4

2.7

2.7

2.9

Pilot burner(Perm/Pilot)

Q349A-1034 (with 0.23P injector)

11.5 BOILER CHECKS PRIOR TO LIGHTING

Ensure that the gas supply is connected but turned

to the ‘OFF’ position. Remove the cover on the low

gas pressure switch and connect a multi-meter

across terminals ‘C & NO’ - to measure circuit

continuity.

Connect a manometer suitable for 50mbar to the

pressure tapping on the switch body and gradually

turn ‘ON’ the gas supply. The switch should operate

at approximately 20mbar - noted on the multi-

meter.

Turn ‘OFF’ the gas supply and undo the pressure

test point on the gas valve inlet and allow the gas

pressure to fall. The switch should operate at

approximately 20mbar - noted on the multi-meter.

11.5.1 Gas Pressure Adjustment

After approximately 30 minutes of normal firing,

connecting a manometer to test point on the

manifold should check the manifold gas pressure.

Minor adjustments to the appliance governor may

be necessary to correct for site gas pressure

conditions.

NOTE:

The above is a first order check. Final

setting must be made using a gas meter.