20

Hampton H35 Direct Vent Freestanding Gas Stove

*As specified in CGA

B149 Installation Code.

Local codes or regula-

tions may require dif-

ferent clearances.

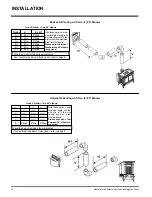

Diagram 2

INSTALLATION

DURA-VENT VENTING

COMPONENTS

The Simpson Dura-Vent Direct Vent System

offers a complete line of component parts for

installation of both horizontal and vertical instal-

lation. Many items are offered in decorative

black, as well as galvanized finish. The galva-

nized pipe and fittings are used for concealed

locations such as attics or where corrosion is

a factor, such as above the roof line. Decora-

tive brass trim kits are available for both wall

thimbles and ceiling support boxes.

Part #

Description

971

Horiz. Termination Kit includes: 90

o

black

elbow, wall thimble cover, horiz. square

termination cap, 24" black pipe, 11" -14"

5/8" adjustable black pipe

970

Basic Horiz. Termination Kit includes:

90

o

black elbow, wall thimble cover,

horiz. square term. cap

978

Vert. Termination Kit includes 0/12 - 6/

12 pitch adjustable flashing, storm col-

lar, low profile term. cap

908B

6" Pipe Length-Black

907B

9" Pipe Length-Black

906

12" Pipe Length Galv.

906B

12" Pipe Length-Black

904

24" Pipe Length Galv.

904B

24" Pipe Length-Black

903

36" Pipe Length Galv.

903B

36" Pipe Length-Black

902

48" Pipe Length Galv.

902B

48" Pipe Length-Black

911B

11"-14 5/8" Adj. Pipe Length-Black

917B

17"- 24" Adj. Pipe Length Black

945

45

O

Elbow Galv.

945B

45

O

Elbow-Black

945G 45

O

Elbow-Swivel Galv.

945BG 45

O

Elbow-Swivel-Black

990

90

O

Elbow Galv.

990B

90

O

Elbow-Black

990G 90

O

Elbow-Swivel Galv.

990BG 90

O

Elbow-Swivel-Black

991

High Wind Term. Cap (Vertical)

980

Vertical Term. Cap

984

Horiz. Sq. Term. Cap

985

Horiz. Sq. High Wind Termination

Cap

982

Snorkel-14" Rise Term.Cap

981

Snorkel-36" Rise Term.Cap

940

Wall Thimble-Support/Box

941

Cathedral/Ceiling-Support/Box

3951

Brass Trim-WallThimble/Ceiling Support

963

Firestop Spacer

943

Flashing 0/12-6/12

943S

Flashing 7/12-12/12

953

Storm Collar

950

Vinyl Siding Standoff

988

Wall Strap

942

Wall Thimble

Diagram 1:

Hint: Apply

silicone to

female end.

DURA-VENT

HORIZONTAL

INSTALLATIONS

1)

Set the unit in its desired location. Check to

determine if wall studs or roof rafters are

in the way when the venting system is

attached. If this is the case, you may want

to adjust the location of the unit.

2)

Direct Vent pipe and fittings

are designed with special

twist-lock connections to

connect the venting sys-

tem to the appliance flue

outlet. A twist-lock appli-

ance adapter is installed

on the unit at the factory.

Assemble the

desired combi-

nation of pipe

and elbows to

the appliance

adapter with

pipe seams

oriented to-

b)

Horizontal runs of vent must be sup-

ported every three feet. Wall straps are

available for this purpose.

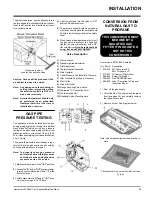

c) Snorkel Terminations:

For installations requiring a vertical rise

on the exterior of the building, 14-inch

and 36-inch tall Snorkel Terminations

and the Riser Vent as shown in Dia. 2

& 2a are available. Follow the same

installation procedures as used for

standard Horizontal Termination. NEV-

ER install the snorkel upside down.

Parts not supplied by Dura-Vent

946-506/P Vent Guard (Optional)

640-530

Riser Vent Terminal (Optional)

948-128

Vinyl Siding Shield for Riser

Vent Terminal

946-228

Horizontal Square Termination Cap

You will require the following components with

your new Direct Vent Freestanding Gas Stove.

Please review your product to make sure you

have everything you need. In the event that you

are missing any part, contact your dealer.

Note: These are the minimum pieces

required. Other parts may be re-

quired for your particular installa-

tion. See above for a list of vent

parts.

If installing termination on a siding covered wall,

a vinyl siding standoff or furring strips can be

used in order to ensure that the termination is

not recessed into siding.

The vinyl siding standoff is required for walls

with vinyl siding.

Minimum components for a Dura-Vent

Horizontal Installation:

A) Dura-Vent Horizontal Termination Kit

B) Wall Thimble (required for combustible

walls)

Minimum components for a Dura-Vent

Vertical Termination:

D) Dura-Vent Vertical Termination Kit. See

above for pipe lengths.

wards the wall or ceiling, as much out of

view as possible. The final positioning of

the pipe and 90

o

elbow assembly is deter-

mined by the mounting orientation of the

adapter on the stove and twist-locked for

a solid connection.

Note:

a)

Twist-lock procedure: Four indenta-

tions, located on the female ends of

pipes and fittings, are designed to slide

straight onto the male ends of adjacent

pipes and fittings, by orienting the four

pipe indentations so they match and

slide in to the four entry slots on the

male ends (diagram 1). Push the pipe

sections completely together, then

twist-lock one section clockwise ap-

proximately one-quarter turn, until the

two sections are fully locked. The fe-

male locking lugs will not be visible from

the outside on the Black Pipe or fittings.

They may be located by examining the

inside of the female ends. Apply seal-

ant "Mill-Pac" to inner pipe and high

temp silicone sealant to outer pipe on

every twist-lock joint.