27 / 48

Hakki Pilke 55 Pro

Translation

Version 3-2022

4.5.

Using the out-feed conveyor

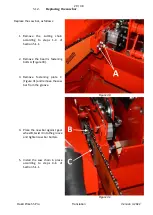

The running speed of the out-feed conveyor can be freely adjusted with adjustment screw A (Figure 29). If

the conveyor is jammed for any reason, the conveyor must be stopped with lever E (Figure 9) and the

machine shut down before the cause is removed. If the issue is at the end of the conveyor (a piece of wood

is stuck between the conveyor and possible extension conveyor), the conveyor belt can be reversed for a

short distance with lever E (Figure 9).

The tightness of the intermediate conveyor’s belt (and the belt’s alignment) can be adjusted as follows:

1.

Loosen fastening nut B (Figure 29).

2.

Tighten/loosen the belt with nut C in Figure 29 (the same amount on both sides of the belt). If the

belt is crooked, loosen nut C (in relation to the spring) on the side towards which you wish to align

the belt better.

3.

When the conveyor belt is at the correct tension and properly aligned, tighten fastening nuts B on

both sides tightly against nut C.

Figure 29.

The out-

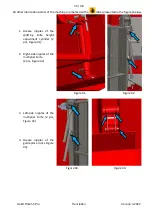

feed conveyor’s belt can be replaced as follows:

1.

Loosen the belt in accordance with the instructions provided above.

2.

Rotate the connection point roughly to the halfway point of the conveyor.

3.

Pull the connection wire out and remove the old belt.

4.

Install the new belt in place in the reverse order.