31 / 48

Hakki Pilke 55 Pro

Translation

Version 3-2022

5.3.

Changing the hydraulic oil and filters

1.

Turn off the machine and

disconnect it from its power

source.

2.

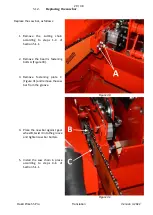

Open the oil tank’s filler cap A.

The tank is located in front of the

work platform on the operator’s

side.

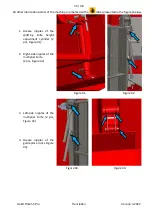

The oil level guard and

thermostat D measure oil level

and temperature in the tank and

warn about insufficient levels or

excessive oil temperature on the

machine’s monitor.

3.

Remove plug C in Figure 34 and

drain the old oil.

4.

Remove the bolts circled in Figure

33, and remove the covers of the

filter housing (2 pcs). Remove the

old filter cartridges and install new

ones. Reattach the covers with the

circled bolts.

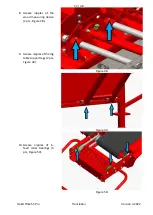

Note! The oil volume is approx. 125

litres, so be prepared to replace the

container more than once as necessary.

Note! Choose the correct type of oil

according to the operating conditions! If

the electric motor is turned on in cold

conditions (below -10°C), the use of an

oil with a viscosity of ISO VG 32 and an

oil heater accessory is recommended.

The recommended oil under normal

conditions is ISO VG 46 (with the oil

temperature no more than 60°C).

5.

Put plug C back in place and feed

the new oil to the tank through

the opening of filler cap A (approx.

125 litres).

6.

Use gauge B (Figure 33) to make

sure that the oil level is near

maximum.

Figure 33.

Figure 34.