22 / 48

Hakki Pilke 55 Pro

Translation

Version 3-2022

If a fault, failure or leak occurs during the test run, determine the cause and take remedial action as

necessary. The machine must be shut down and disconnected from the power source for the duration of

both the diagnostics and repairs.

4.2.

Placing logs on the in-feed conveyor

We recommend the use of auxiliary devices, such as the HakkiFeed 472 log table. If a log table is not

attached to the machine, the maximum allowed log length is 4.5 m. Always lift and place wood on the input

table in a safe manner that does not endanger the operator.

Note! The placing of logs directly onto the in-feed conveyor with a loader is strictly prohibited.

Note! Ensure that the log's centre of gravity stays on the conveyor.

4.3.

Feeding and sawing wood

The in-feed conveyor feeds the wood into the firewood processor. Move timber into the machine by turning

joystick J shown in Figure 9. The feed can be cancelled by turning the joystick to the left. The machine has

been designed to be used with the log table model Hakki Pilke HakkiFeed 471 or 472. Do not use the

machine without a suitable log table due to the weight of the logs.

When feeding wood into the machine, make sure that it does not present a risk of your clothes, hands or

other parts getting caught in the machine, such as due to the shape of the log. Do not use your hand to

guide the log into the cutting section. Adjust the wood measuring device to the desired length and make

sure that the speed of the out-feed conveyor belt is suitable by adjusting it.

1.

Choose the log to process. Note that the maximum log diameter is 55 cm. The knottiness and shape

of the log can increase the diameter.

2.

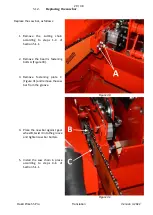

Use joystick J to feed the log into the machine with the in-feed conveyor. Check that the log is not

oversized and that no part of it collides with the log press or saw bar during feeding.

3.

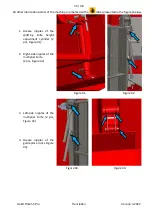

When the log stops in the hydraulic measuring device for cutting, cut the log by pressing button D

(Figure 10) on the joystick. This will activate the saw chain and sawing cycle automatically.

4.

Return the saw bar to the upper position by releasing button D (Figure 10).

5.

Do not start the next cutting motion before the splitting process has turned to reverse back.

Note! Do not operate the feed during sawing or when the saw bar is not fully in the upper position.

Note! Use the machine with HakkiFeed log tables only. Do not lift logs into the machine with a loader!

Note! When using the machine, always make sure that no one else is within the danger zone (10 m) of

the machine or the log table connected to it. See Section 1.5.

4.3.1.

Hydraulic log press

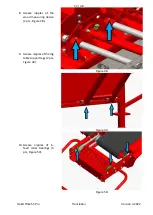

The Hakki Pilke 55 Pro firewood processor is equipped with a hydraulic log press, which always

automatically

presses the log against the in-feed conveyor during the cutting motion. If necessary, the

operator can raise/lower the log press with joystick J (Figure 9) by moving the controller

forwards/backwards. The operator must ensure that the log being fed into the machine does not collide

with the log press due to variations in log size, for example.

Note!

When feeding in a new log, always raise the log press to the upper position!