! WARNING

These instructions are intended as an aid to qualified, licensed service personnel for proper installation,

adjustment and operation of this unit. Read these instructions thoroughly before attempting installation

or operation.

Failure to follow these instructions may result in improper installation, adjustment,

service or maintenance possibly resulting in fire, electrical shock, property damage, personal injury

or death.

This product is designed and manufactured to permit installation in accordance with National Codes.

It

is the installer's responsibility to install the product in accordance with National Codes and/or

prevailing local codes and regulations

. The manufacturer assumes no responsibility for equipment installed

in violation of any codes or regulations.

The United States Environmental Protection Agency (EPA) has issued various regulations regarding

the introduction and disposal of refrigerants in this unit.

Failure to follow these regulations may harm

the environment and can lead to the imposition of substantial fines. Because these regulations may vary

due to the passage of new laws we suggest that any work on this unit be done by a certified technician.

Should you have any questions please contact the local EPA office.

The manufacturer's warranty does not cover any damage or defect to the air conditioner caused by the

attachment or use of any components, accessories or devices (other than those authorized by the manufacturer)

into, onto, or in conjunction with the air conditioner.

You should be aware that the use of unauthorized

components, accessories or devices may adversely affect the operation of the air conditioner and

may also endanger life and property

. The manufacturer disclaims any responsibility for such loss or

injury resulting from the use of such unauthorized components, accessories or devices.

Attach the service panel to the outdoor unit securely

. If the service panel is not attached securely, it

could result in a fire or an electric shock due to dust, water, etc.

These instructions are intended as an aid to qualified, licensed service personnel for proper installation,

adjustment and operation of this unit. Read these instructions thoroughly before attempting installation

or operation.

Failure to follow these instructions may result in improper installation, adjustment,

service or maintenance possibly resulting in fire, electrical shock, property damage, personal injury

or death.

This product is designed and manufactured to permit installation in accordance with National Codes.

It

is the installer's responsibility to install the product in accordance with National Codes and/or

prevailing local codes and regulations

. The manufacturer assumes no responsibility for equipment installed

in violation of any codes or regulations.

The following information should be read carefully prior to installing units with scroll compressors.

1.PUMP DOWN PROCEDURE

CAUTION: Scroll compressors should never be used to evacuate the air conditioning system. Vacuums this low can cause

internal electrical arcing resulting in a damaged or failed compressor.

2.CRANKCASE HEATER

Scroll equipped units do not have or do not require a crankcase heater.

3.TIME DELAY COMPONENT

The time delay is located in the low voltage control circuit. When the compressor shuts off due to thermostat operation or a

power failure, this components keeps the compressor off for at least 30 seconds which allows the system pressure to equalize.

4.UNBRAZING SYSTEM COMPONENTS

If the refrigerant charge is removed from a scroll equipped unit by bleeding the high side only, it is sometimes possible for the

scrolls to seal, preventing pressure equalization through the compressor. This may leave the low side shell and suction line tubing

pressurized. If a brazing torch is then applied to the low side while the low side shell and suction line contains pressure, the

pressurized refrigerant and oil mixture could ignite when it escapes and contacts the brazing flame. To prevent this occurrence,

it is important to check both the high and low side with manifold gauge before unbrazing, or in the case of repairing a unit on an

assembly line, bleed refrigerant from both the high and low side.

Message to Owner

These instructions should be carefully read and kept near the product for future reference. While the instructions are

addressed primarily to the installer, useful maintenance information is included. Have your installer acquaint you with

the operating characteristics of the product and periodic maintenance requirements.

Содержание HR18D2VAR

Страница 1: ...No 0010578573 HR18D2VAR HR24D2VAR HR30D2VAR 13 SEER 1 5 to 3 0 Ton HR36D2VAR ...

Страница 13: ...5 5 ...

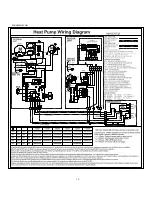

Страница 17: ...HR18 36D2VAR 15 YL GR ...

Страница 18: ...Made in P R C ...