Copper Wire Size - AWG

(1% Voltage Drop)

Supply Circuit Supply Wire Length - Ft

Ampacity 50 100 150 200

15

14 10 8 6

20

12 8 6 4

25

10 8 6 4

30

10 6 4 4

35

8 6 4 3

40

8 6 4 2

45

6 4 3 2

50

6 4 3 1

12

The condensing unit rating plate and the tables of "Physical and Electrical Specifications / Outdoor

Units" (Table 1) provide pertinent data necessary for the selection of proper size electrical service

and over-current protection devices.

Table 6

provides data on the minimum copper wire size as a function of supply wire length and circuit

ampacity.

Table 6: Minimum Wire Size Based on N.E.C. for 60 C Type Copper Conductors Below 100

Ampacity.

The owner should be made familiar with the location of the over-current protection, the proper size

for this application and the proper procedure for disconnecting power service to the unit.

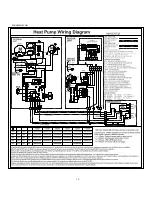

The condensing unit control wiring requires a 24 Volt minimum, 25 VA service from the indoor

transformer as shown on the wiring diagram.

7.SYSTEM STARTUP

1.Turn thermostat to "OFF", turn on power supply at disconnect switch.

2.Turn temperature setting as high as it will go.

3.Turn fan switch to "ON". Indoor blower should run. Be sure it is running in the right direction.

4.Turn fan switch to "AUTO". Turn system switch to "COOL" and turn temperature setting below

room temperature. Unit should run in cooling mode.

5.The compressor, indoor blower, and outdoor fan should now be running. Make sure cool air is

supplied by the unit.

6.Turn the fan switch to the "Auto" position. The blower should stop 90 seconds later.

7.Turn system switch to "Heat" and fan switch to "Auto" .

8.Slowly raise the heating temperature setting. The compressor, indoor blower and outdoor fan should

now be running.

9.If unit operates properly on the heating cycle, raise the heating temperature setting high enough.

10.For thermostats with emergency heat switch return to startup.

Содержание HR18D2VAR

Страница 1: ...No 0010578573 HR18D2VAR HR24D2VAR HR30D2VAR 13 SEER 1 5 to 3 0 Ton HR36D2VAR ...

Страница 13: ...5 5 ...

Страница 17: ...HR18 36D2VAR 15 YL GR ...

Страница 18: ...Made in P R C ...