Page 16

31-5000726 Rev. 0

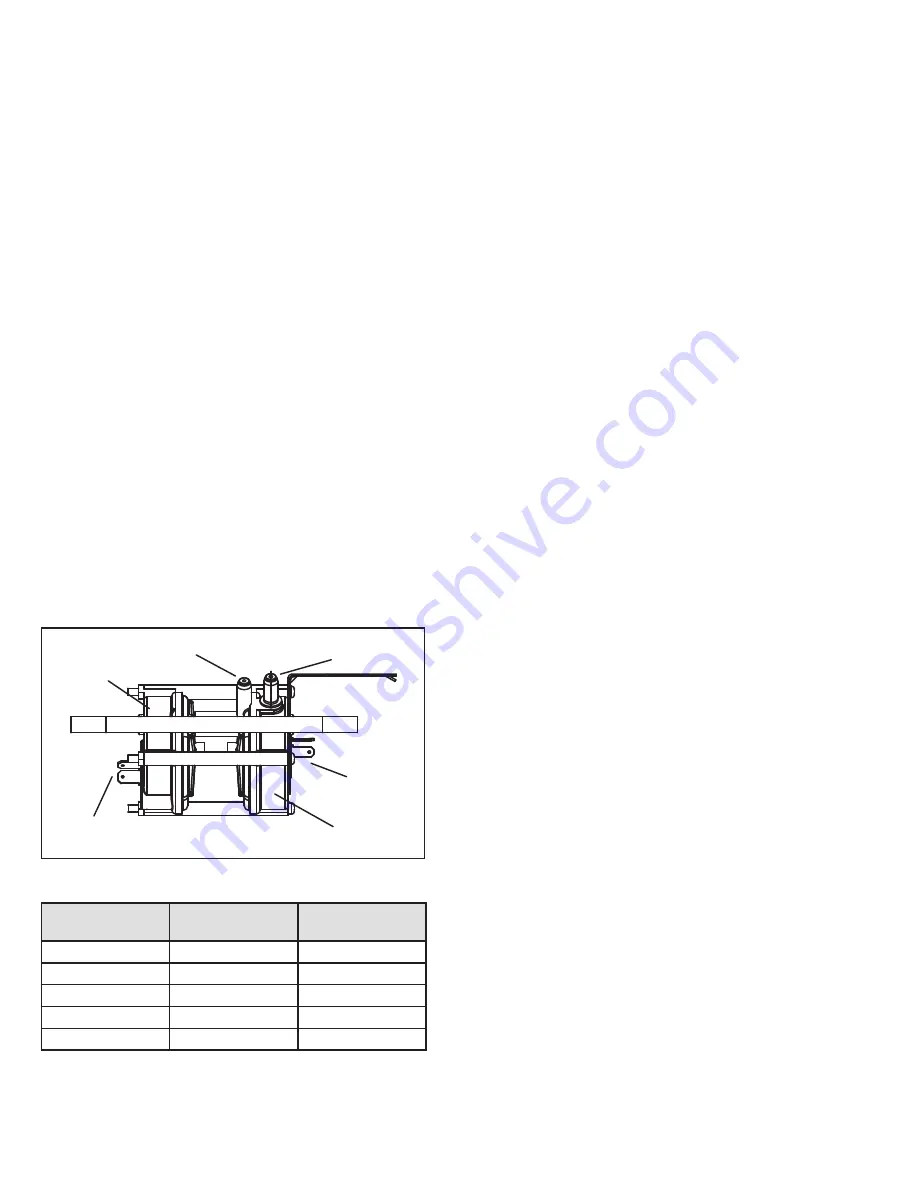

Combustion Air Inducer Pressure Switch (S18)

NF96UV series units are equipped with a dual combustion

air pressure switch (first and second stage) located on the

combustion air inducer orifice bracket. See Figure 11. The

switch is connected to the combustion air inducer housing

by means of a flexible silicone hose. It monitors negative

air pressure in the combustion air inducer housing.

The switches are a single-pole single-throw proving

switch electrically connected to the integrated control.

The purpose of the switch is to prevent burner operation

if the combustion air inducer is not operating or if the flue

becomes obstructed. On heat demand (first or second

stage) the switch senses that the combustion air inducer is

operating. It closes a circuit to the integrated control when

pressure inside the combustion air inducer decreases to a

certain set point.

Set points vary depending on unit size. See Table 6.

The pressure sensed by the switch is negative relative

to atmospheric pressure. If the flue becomes obstructed

during operation, the switch senses a loss of negative

pressure (pressure becomes more equal with atmospheric

pressure) and opens the circuit to the furnace control and

gas valve. A bleed port on the switch allows relatively

dry air in the vestibule to purge switch tubing, to prevent

condensate build up.

NOTE:

The switch is factory set and is not field adjustable.

It is a safety shut-down control in the furnace and must

not be by-passed for any reason. If switch is closed or

bypassed, the control will not initiate ignition at start up.

Figure 11. Combustion Air Pressure Switch

3/16 Terminals

Low Fire Switch

High Fire Switch

1/4" Terminals

Tap (negative - )

Tap (po)

Unit

Set Point

Low Heat

Set Point

High Heat

-045

0.40

0.70

-070

0.50

0.85

-090

0.50

0.85

-110

0.50

0.90

-135

0.45

0.90

Table 6.

Pressure Switch Setting 0 - 4500’

Pressure Switch Check

To check pressure switch differential, refer to Figure 12

and use the provided fittings and tubing to follow the steps

below.

1.

Remove thermostat demand and allow unit to cycle

off.

2.

Remove the tubing from the negative side (red and

black or red) and positive side (black) of the pressure

switch (leave both connected to cold end header box).

3.

Take the 2” length square tubing and connect to the

positive (+) side of the pressure switch. Take the 10”

length square tubing and tee into the tubing from the

positive side of the cold end header box and the other

side of the 2” square tubing. Connect the other end of

the 10” square tubing the the positive (+) side of the

measuring device.

4.

Take a second piece the 2” length square tubing and

connect to the negative (-) side of the pressure switch.

Take a second piece of 10” length square tubing and

tee into the tubing from the negative (-) side of the cold

end header box and the other side of the 2” square

tubing. Connect the other end of the 10” square tubing

the the negative (-) side of the measuring device.

5.

Operate unit and observe manometer reading.

Readings will change as heat exchanger warms.

a. Take one reading immediately after start-up.

b. Take a second reading after unit has reached

steady state (approximately 5 minutes). This

will be the pressure differential. The pressure

differential should be at least 0.15” greater than

those listed in Table 6. Readings in table are the

set points or “break points”.

6.

Remove thermostat demand and allow to cycle off.

7.

Replace original pressure switch tubing.

NOTE:

Pressure differential values (set point) in table are

the ”break”, or ”open” specifications. ”Make”, or ”close”

pressure differentials are 0.15” greater than the set points

listed in table.