Manager:

LOW

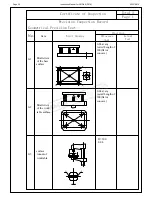

CRUSHING

All electrical enclosures should only be opened with a tool that is not to be kept with the machine.

Never clean or dust machine when power is on.

Hazard

Drilling Mac

hine

D

NEW

MACHINER

Y

HAZARD IDENTIFICA

TION,

ASSESSMENT & CONTROL

STRIKING

MEDIUM

Ensure workpieces are tightly secured on machine.

Item

B

Authorised and signed by:

Safety of

ficer:

LOW

PLANT SAFETY

PROGRAM

No.

Hazard

Identification

Developed in Co-operation Between

A.W

.I.S.A

and

Australia Chamber of Manufactures

This program is based upon the

Australian W

orksafe Standard for Plant(NOHSC:1010-1994)

Assessment

M

H

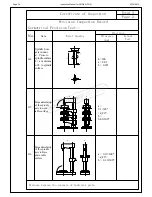

ELECTRICAL

A

C

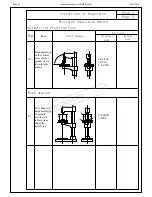

OTHER HAZARDS, NOISE.

F

ENT

ANGLEMENT

CUTTING, ST

ABBING,

O

LOW

PUNCTURING.

MEDIUM

Isolate power to machine prior to any checks or maintenance being carried out.

SHEARING

HIGH

Risk Control Strategies

(Recommended for Purchase / Buyer / User)

Secure & support work material on drill table.

Eliminate, avoid loose clothing / Long hair etc.

Isolate power to machine when changing speeds or maintenance is being carried out.

W

ear safety glasses.

Do not adjust or clean until the machine has fully stopped.

MEDIUM

HIGH

TEMPERA

TURE

MEDIUM

W

ear appropriate protective clothing to prevent hot swarf.

Machine should be installed & checked by a Licensed Electrician.

Revised Date:

www

.machineryhouse.com.au

www

.machineryhouse.co.nz

Aug-08

Make sure all guards are secured shut when machine is on.

Plant Safety Program to be read in conjunction with manufactures instructions

Ensure correct spindle direction when drilling..

W

ear hearing protection as required.

For Radial

Arm Drills ensure that arm is locked before drilling.

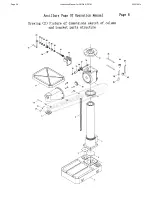

Page 43

Instruction Manual for GHD-50 (D178)

23/12/2014