Operation Manual

Total 26

page 20

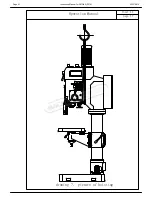

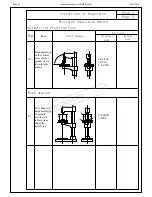

Installation:

Working area of the machine shall be the size when the worktable rounds its column in one

cycle. Its diameter is about

Ø2000

mm. Further more, space for the work pieces, toolbox, and

machine accessories as well as operating and maintenance space must be considered.

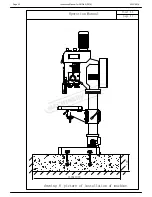

The machine should be placed on a solid ground. No foundation construction is required if

ground of workshop is solid enough. However, we suggest that you’d better to make a

foundation as per the attached drawing 8 and shall consider some space for foundation screw

bolts use.

When the foundation is completely dry, the machine could be laid down on the adjustable

pad. Concrete could be filled when screw bolts are placed. Fastening screw bolts after

concrete is completely dry. Leveling the machine first, required tolerance should not be

over 0.04/1000mm both in horizontal and cross plane. Checking all items of the accuracy as

per the table sheet of the certificate. Accuracy value for each checked item must not be over

the required value.

Preparation before machine running:

A strict checking, testing and try cutting of the machine have been made before machine

delivery. No adjustment of the machine itself is necessary. Before machine running, clean all

surfaces of the machine first by using cloth with kerosene or gasoline, checking all

lubrication points then turn the main switch of the machine to the “on” position, running the

machine with middle or slow speed and checking all revolution direction is correct, operating

levers are in a correct position, checking machine noise and working temperature are all ok.

The machine should be running for a certain period of time, then it could be used if no any

un-normal condition happened.

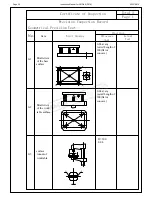

7.

Use and operation of the machine

:

For the operating levers, handles, electric switches and buttons, please refer to the diagram 1

and diagram 4.

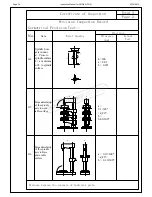

Mounting and dismounting of tool cutters:

The machine equipped with a tool dismounting device to be controlled by a nob ( 16 ). Push

forward the nob ( 16 ) to the spindle box direction when tool mounting is required. As for

dismounting tool cutters, pull out the nob ( 16 ), hold the tool cutter by left hand,

meanwhile, turn the feed lever ( 4 ) by right hand, then the spindle quill goes up rapidly,

the tool cutter will fall down until tool taper shank strokes the shaft of spindle.

Page 22

Instruction Manual for GHD-50 (D178)

23/12/2014