Page 2

About this Guide

The information in this guide has been carefully

checked and is believed to be accurate. However,

Hach Ultra assumes no responsibility for any

inaccuracies that may be contained in this guide.

In no event will Hach Ultra be liable for direct,

indirect, special, incidental, or consequential

damages resulting from any defect or omission in

this guide, even if advised of the possibility of

such damages. In the interest of continued

product development, Hach Ultra reserves the

right to make improvements in this guide and the

products it describes at any time, without notice or

obligation.

Instrument Controls

The instrument front panel provides these user

interfaces:

•

A touch screen acting as display, touch

pad and keyboard.

•

A LED, showing when instrument is on.

•

A buzzer sounds each time the screen is

touched, and when an event alarm is set.

Sound level and type can be adjusted.

Touch Screen

The user interface on the front panel is a 320x240

pixels color display with touch screen. To make

navigation user friendly, the interface software is

Windows CE based, providing easy selection

through menus.

All the measurement, configuration, calibration

and "standard service" routines can be called by

pressing buttons and menus bar on screen.

Measurement display shows one measurement

slope per sensor in function (up to 3 lines for a 3

channel Orbisphere 51x).

Special Keys on Portable Instruments

The sample mode start/stop button starts

the measurement process when in sample

mode. Pressing the button again manually

interrupts the process and an “aborted” message

is displayed in the numeric view.

The state of the battery is indicated at the bottom

of the measurement view. Pressing the battery

icon calls the “Batteries” state window.

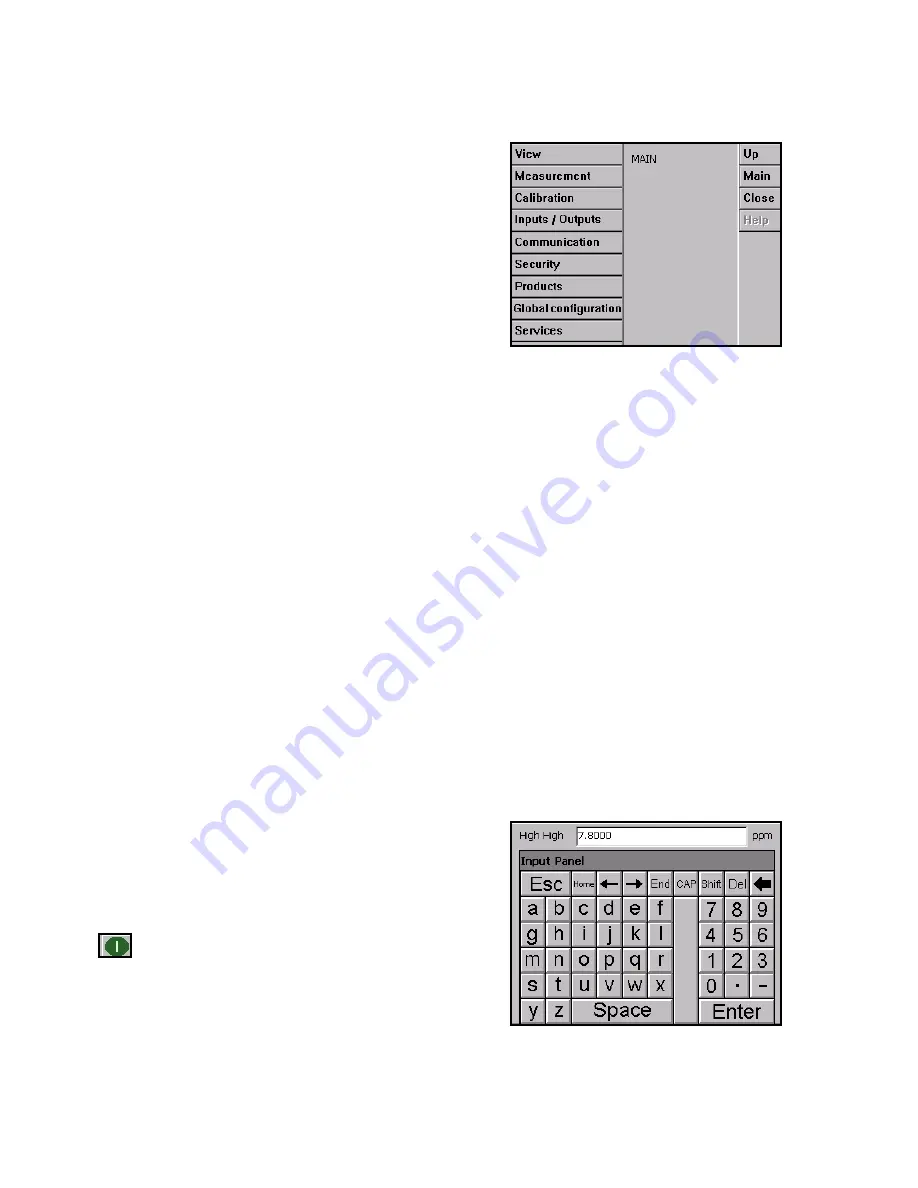

Menu Navigation

Pressing the “menu” button in the header bar calls

the main menu. The display is made of three

columns:

•

Left column is the menus, or submenus

(greyed out options are not available)

•

Center column shows a tree view of the

actual position inside the menu structure

•

Right column has the following generic

controls:

•

Up

- Return to a previous menu

•

Main

- Jump directly to the main menu

•

Close

- Close the menu and return to

the measurement view display

•

Help

- Help topics relating to the

current menu

Virtual Keyboard

When a text box (alphanumeric field) has to be

edited and is pressed, a virtual keyboard appears

on screen. It can be used as a PC keyboard

(pressing CAP give access to special keys).

Once values have been entered, press the

Enter

key to confirm and exit the virtual keyboard.

Operating Information

Содержание ORBISPHERE 511

Страница 1: ...Operator Quick Guide ORBISPHERE 510 511 512 Revision G 05 11 2008...

Страница 16: ......