24

Rossi

Operating instructions − UTD.045.06-2013.00_TR_EN

TR

EN

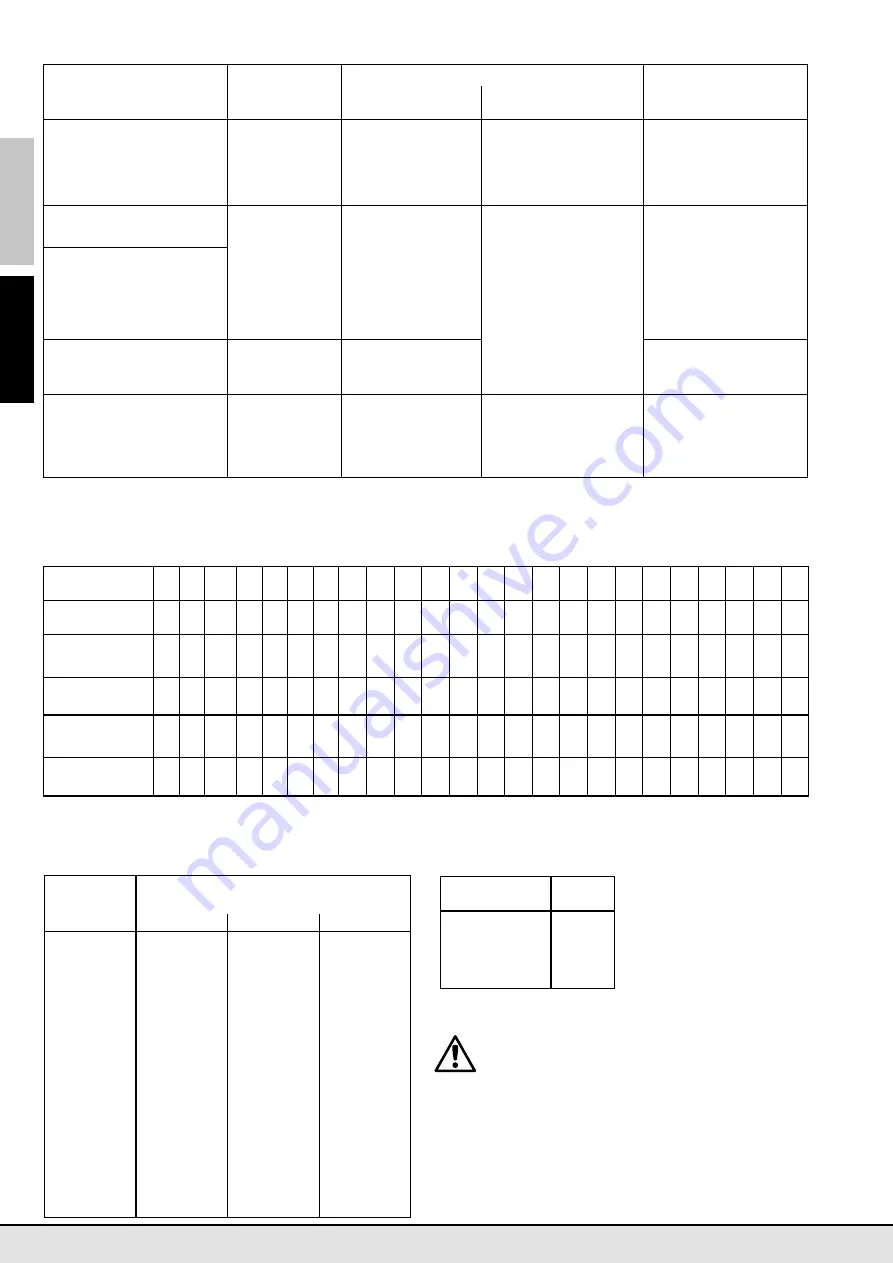

Painting table

Table of tightening torques for axial fastening bolts and shrink disc

2)

1) For worm gear reducers UNI 5931-84.

2) The bolts of shrink disc must be gradually and uniformly tightened, with continuous sequence (not diagonally!) and in several phases up to the reaching of maximum tightening torque stated on table.

1) For servo gear reducers (cat. SR) the final colors is matt black RAL 9005.

2) Integrated low backlash planetary servogearmotors.

3) Before adding further coats of paint, properly protect the seal rings and carefully degrease and sand the gear reducer surfaces.

Note

- Class 8.8 is usually sufficient.

- Before tightening the bolt be sure that the eventual centering of flanges are inserted properly

- The bolts are to be diagonally tightened with the maximum tightening torque.

Table of tightening torques fastening bolts (foot,

flange, hub clamps and flexible half-coupling bolts)

Table of tightening torques for plugs

Product

Size

Internal painting

External painting

Notes

Final color

Blue RAL 5010

Features

Worm

32 … 81

Epoxy powder

(prepainted)

Epoxy powder

(prepainted)

Resistant to atmospheric and

aggressive agents

(atmospheric corrosivity category

C3

according to ISO 12944-2)

Suitable for further coats of

dual-compound paints only

3)

Machined parts remain

unpainted and are protect-

ed with an easily removable

anti-rust oil (before painting

remove the protective oil)

Helical and

bevel helical

40 … 81

Coaxial type

32 … 41

Worm

100 … 250

Single-compound

ester epoxy or

phenolic resin

basis primer

(prepainted)

Single-compound ester

epoxy or phenolic resin

basis primer

(prepainted)

+

Water-soluble

polyacrylic

dual-compound enamel

Resistant to atmospheric

and aggressive agents

(atmospheric corrosivity category

C3

according to ISO 12944-2).

Suitable for further coats

of dual-compound paints

only

3)

Machined parts are pain-

ted wih water-soluble

polyacrylic dual-compound

enamel

The internal painting does

not resist polyglycol syn-

thetic oils (polyalphaolefines

synthetic oils are suitable).

Remove by a scraper or

solvent the possible paint

of gear reducer coupling

surfaces

Coaxial type

50 … 81

Helical and

bevel helical

100 … 631

Coaxial type

100 … 180

Right angle

(cat. L)

160 … 320

Right angle

(cat. L)

80 … 125

–

Water-soluble

polyacrylic

dual-compound enamel

Remove by a scraper or

solvent the possible paint

of gear reducer coupling

surfaces

Shaft mounted

Coaxial

2)

56 … 142

–

Dual-compound epoxy

polyamide primer

+

Water-soluble dual-com-

pound polyacrylic enam-

el (matt black RAL 9005)

Resistant to atmospheric

and aggressive agents

(atmospheric corrosivity category

C3

according to ISO 12944-2).

Suitable for further coats of

dual-compound paints only

3)

Machined parts remain

unpainted and are protect-

ed with an easily removable

anti-rust oil (before painting

remove the protective oil)

Bevel helical

2)

85 … 142

Worm gear

reducer size

32 40 50

– 63,

64 –

80,

81 100

125,

126 160 161 – 200 – 250 –

–

–

–

–

–

–

–

–

Helical and bevel

helical size

40 50

–

63 64 80 81 100 125 140 – 160 180 200 225 250 280 320,

321 360

400,

401

450,

451

500,

501

560,

561

630,

631

Bolts for axial fastening

UNI 5737-88

class 10.9

M8

1)

M8

1)

M10

1)

M10 M10 M10 M10 M12 M14 M16 M16 M20 M20 M24 M24 M30 M30 M36 M36 M30 M30 M36 M36 M36

M

s [N m]

for rings or bush

29 35

43

43 43 51 53

92 170 210 210 340 430 660 830 1350 1660 2570 3150 –

–

–

–

–

Bolts for axial fastening

UNI 5737-88

class 10.9

–

M5

–

M6 M6 M6

–

M8 M8 M8

– M10 M10 M12 M12 M16 M16 M16 M16 M20 M20 M20 M20 M24

M

s [N m]

for shrink disc

–

04

–

12 12 12

–

30

30

30

–

60

60 100 100 250 250 250 250 490 490 490 490 840

Bolt

Ms [N m]

UNI 5737-88, UNI 5931-84

cl. 8.8

cl. 10.9

cl. 12.9

M4

2,9

4

–

M5

6

8,5

10

M6

11

15

20

M8

25

35

40

M10

50

70

85

M12

85

120

145

M14

135

190

230

M16

205

290

350

M18

280

400

480

M20

400

560

680

M22

550

770

930

M24

710

1000

1200

M27

1000

1400

1700

M30

1380

1950

2350

M33

2000

2800

3400

M36

2500

3550

4200

M39

2950

4200

5000

M42

4100

5800

6900

M45

5000

7000

8400

M48

6100

8600

10300

M56

9800

13800

16500

Thread

dimension

M

s [N m]

G 1/4’’

7

16 MB

14

G 1/2’’

14

G 3/4’’

14

G 1’’

25

Attention!

Before tightening, carefully degrease the bolts.

For strong vibrations, heavy duties, frequent motion

reversals apply a thread-braking seal type Loxeal 23-18 or

equivalent.