22

Rossi

Operating instructions − UTD.045.06-2013.00_TR_EN

TR

EN

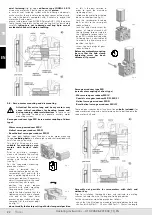

axial fastening

(fig. b), apply

adhesive type LOXEAL 58-14

also on the motor shaft part laying under the

pinion

;

– in case of axial fastening system with hub clamp and dowels,

make sure that they do not overhung from spacer external surfa-

ce: screw the dowels completely and, if necessary, imprint the

motor shaft with a point;

– grease (with grease type KLÜBER Petamo GHY 133N) the pinion

teeth, the seal ring rotary seating and the ring itself, and assemble

carefully,

taking care not to damage seal ring lip in case of

accidental shock with pinion toothing

.

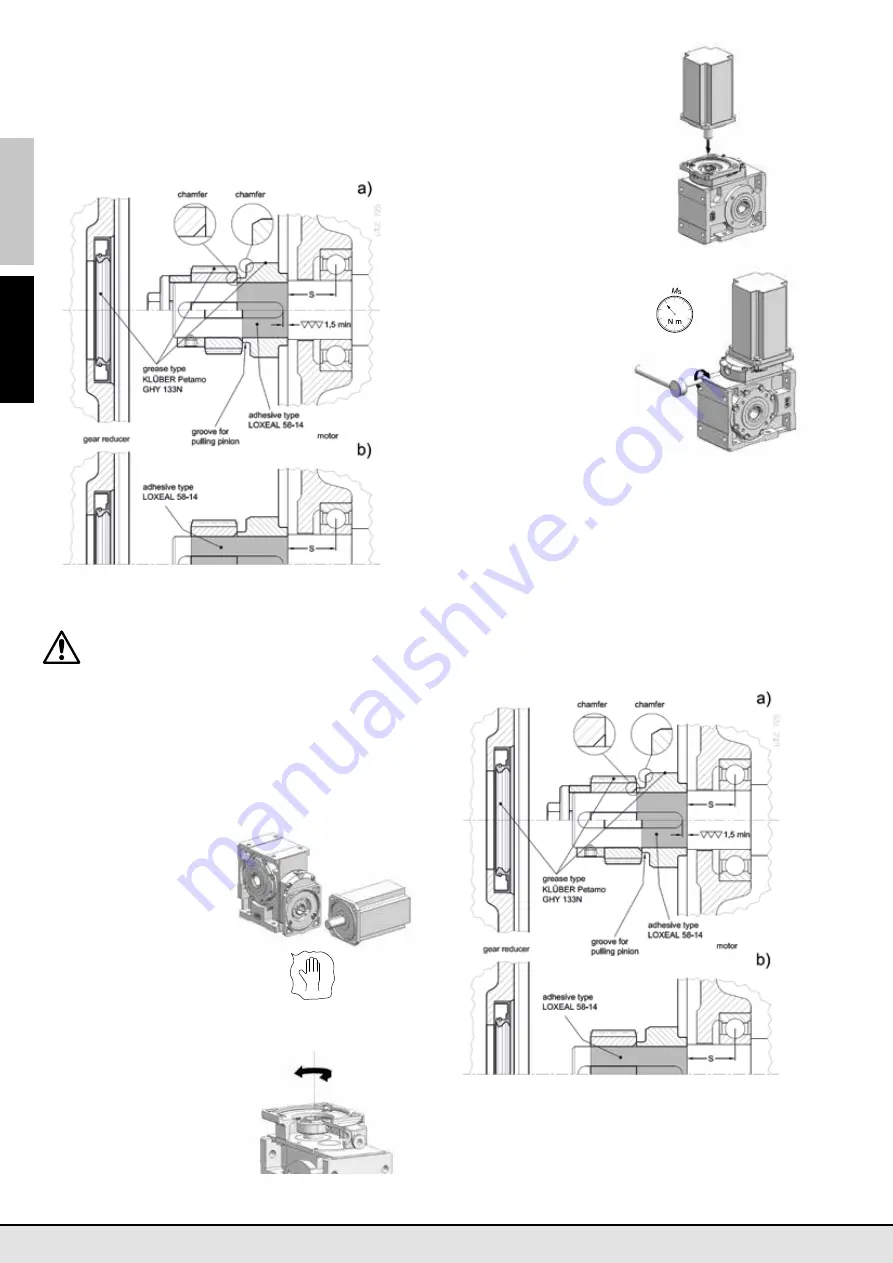

9.5 - Servo motor mounting and dismounting

Attention! Excessive long and heavy motors may

cause critical conditions for bending torque and,

during running, abnormal vibrations

. In these cases,

it is advisable to adopt an adequate auxiliary motor

mounting system.

Servo gear reducer type MR (servo motor coupling of direct

type):

–

Worm servo gear reducer MR V

–

Helical servo gear reducer MR 2I

–

Bevel-helical servo gear reducer MR CI

The servo gear reducer input face has a servo motor mounting

flange,

including bolts,

a hollow high speed shaft provided with

axial slots and hub clamp.

This kind of fitting can be even

suitable for mounting servo

motors with keyless shaft

end

.

Prior to installation, throughly

clean and lubricate the mating

surfaces to avoid the risk of

seizing and fretting corrosion

(see fig. 1).

For the servomotor mounting

proceed as follows:

–

when a lowered key is

needed, replace the key on the

servomotor shaft end with the

one supplied together with the

servo gear reducer; if necessary,

adjust it accordingly to the servo

motor shaft keyway length;

–

position the gear reducer

vertically with motor mounting

flange upwards (see fig. 2);

– rotate the hub clamp so that the

tightening screw head is aligned

with one of the input holes

present on gear reducer flange,

removing first the relevant plugs

(see fig. 2);

–

do not modify the factory setting of hub clamp axial position

fi g. 1

fi g. 2

as this is the best solution in

order to reach the maximum

tightening effect;

– introduce the motor from the top

down to shoulder (see fig. 3);

– lock the servomotor fasetning

bolts or nuts to the servo gear

reducer flange;

–

lock the hub clamp screw by

means of torque wrench until

the tightening torque stated in

the tightening torque table (at

page 24) is reached (also during

this operation it is advisable not

to modify the hub clamp axial

position, see fig. 4);

– screw the hole plugs of gear

reducer flange.

Before any motor dismounting

be sure that the hub clamp

tightening screw has been

unloosed, if present

.

Servo gear reducer type MR

(servo motor coupling of direct type)

–

Worm servo gear reducer MR IV

–

Coaxial servo gear reducer MR 2I, MR 3I

–

Helical servo gear reducer MR 3I

–

Bevel-helical servo gear reducer MR ICI

The servo gear reducer input face has a flange (

bolts included

) for

servo motor mounting and a helical pinion gear to be fitted onto the

servo motor shaft end.

Assembly not possible for servomotors with shaft end

without key

.

Prior to installation, thoroughly clean and lubricate the mating

surfaces to avoid the risk of seizing and fretting corrosion.

For the servo motor mounting proceed as follows:

– check that the fit-tolerance (standard locking) between hole and

shaft end is K6/j6 for D

≤

28 mm, J6/k6 for D

≥

38 mm; the length

fi g. 3

fi g. 4